Waterborne epoxy anticorrosive paint and preparation method thereof

An anti-corrosion coating, water-based epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of increased organic volatiles, inconvenient use, and increased costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

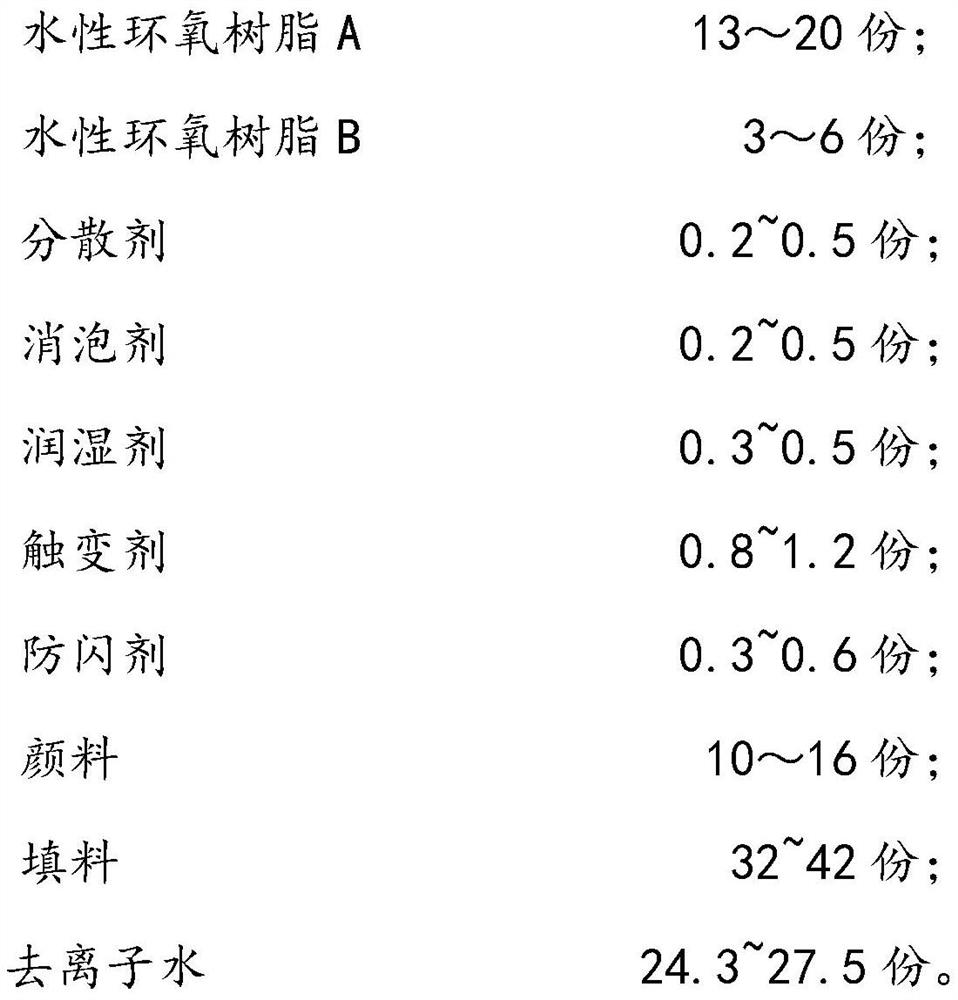

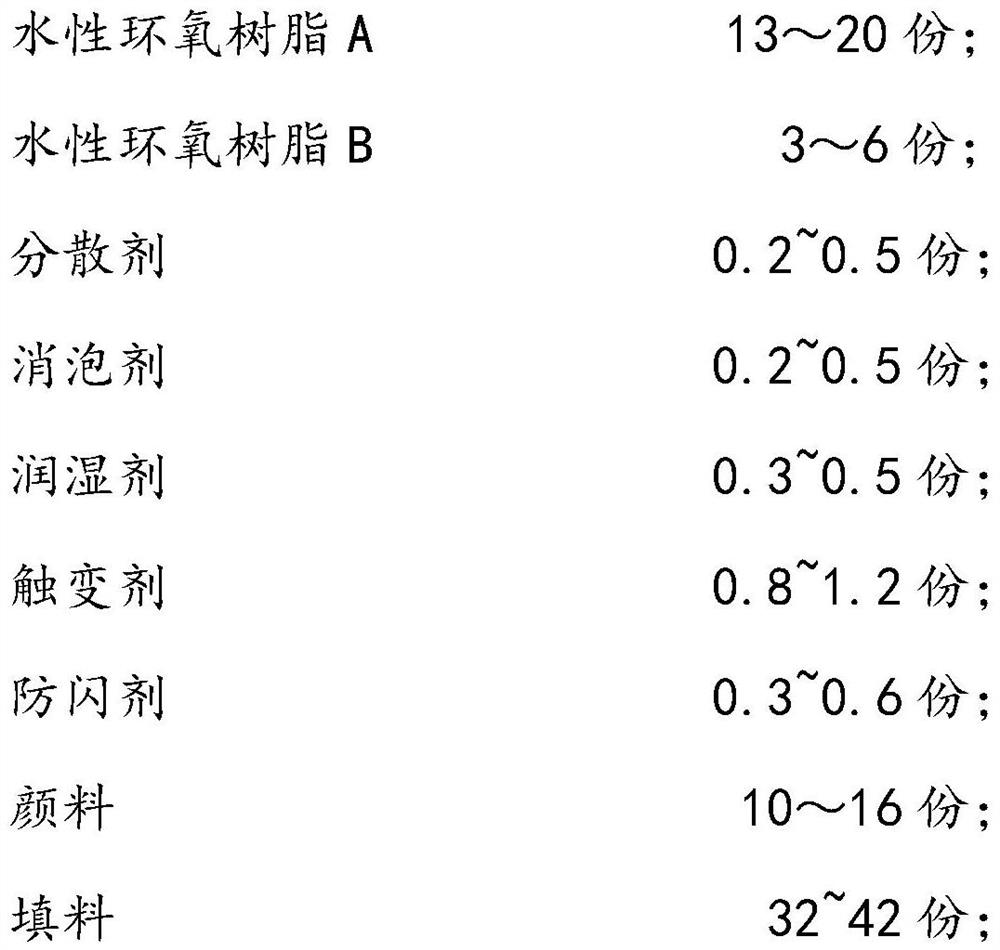

Method used

Image

Examples

Embodiment 1

[0045] In above-mentioned embodiment 1:

[0046] Waterborne epoxy resin B adopts diglycidyl isophthalate;

[0047] The dispersant is 650U; the defoamer is 285W; the wetting agent is 470U; the thixotropic agent is water-based bentonite;

[0048] The water-based curing agent adopts modified polyamide;

Embodiment 2

[0050] Waterborne epoxy resin B adopts diglycidyl hexahydrophthalate;

[0051]The dispersant uses 690W defoamer, uses 280W wetting agent, uses 360S thixotropic agent, and uses water-based silicate;

[0052] The anti-flash agent adopts Puwei F5100

[0053] The water-based curing agent adopts modified alicyclic amine;

Embodiment 3

[0055] Waterborne epoxy resin B adopts diglycidyl adipate;

[0056] The dispersant is 520S;

[0057] The defoamer is 290W, and the wetting agent is 385S;

[0058] The thixotropic agent adopts organically modified hectorite clay;

[0059] The anti-flash agent adopts Puwei F5100;

[0060] The water-based curing agent adopts modified polyamidoamine;

[0061] In Comparative Example 1 and Comparative Example 2, except for water-based epoxy resins A and B, the specific raw materials and ratios adopted are consistent with those in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com