Making process of low-sugar low-salt Dongpo litchi cookies

A production process, lychee technology, applied in the production process of Dongpo lychee cookies, can solve the problems that large-scale machinery is not conducive to small workshop family production, easy to produce obesity, greasy taste, etc., to prevent hypoglycemia and other diseases, golden color , nutritious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

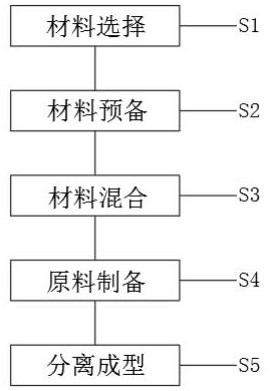

[0026] see figure 1 , a low-sugar and low-salt Dongpo lychee cookie manufacturing process, comprising the following steps:

[0027] S1: material selection, the ingredients of the low-sugar and low-salt Dongpo lychee cookies are as follows: 160 parts of Hefeng butter, 185 parts of ghee, 240 parts of powdered sugar, 5 parts of salt, 160 parts of milk, and 595 parts of low flour , 33 parts of milk powder, 20 parts of custard powder, 155 parts of dried lychee;

[0028] S2: Material preparation, put 150 parts of dried lychees obtained according to S1 into a heater for heating at medium temperature for 4 minutes, put 150 parts of dried lychees after heating on the top of the cutting board, and chop 150 parts of dried lychees with a knife 160 parts of milk obtained according to S1 are put into a container, and 150 parts of dried lychees are put into 160 parts of milk for soaking;

[0029] S3: Mix the materials. According to S1, put 160 parts of Hefeng cream, 185 parts of ghee, 240 ...

Embodiment 2

[0039] see figure 1 , a low-sugar and low-salt Dongpo lychee cookie manufacturing process, comprising the following steps:

[0040] S1: Material selection, the ingredients of the low-sugar and low-salt Dongpo lychee cookies are as follows: 170 parts of Hefeng cream, 200 parts of ghee, 250 parts of powdered sugar, 3 parts of salt, 150 parts of milk, and 580 parts of low flour , 30 parts of milk powder, 20 parts of custard powder, 150 parts of dried lychee;

[0041] S2: Material preparation, put 150 parts of dried lychees obtained according to S1 into a heater for heating at medium temperature for 4 minutes, put 150 parts of dried lychees after heating on the top of the cutting board, and chop 150 parts of dried lychees with a knife , put 150 parts of milk obtained according to S1 into a container, put 150 parts of chopped lychee into 150 parts of milk and soak;

[0042] S3: Mix the materials. According to S1, put 170 parts of Hefeng butter, 200 parts of ghee, 250 parts of pow...

Embodiment 3

[0052] see figure 1 , a low-sugar and low-salt Dongpo lychee cookie manufacturing process, comprising the following steps:

[0053] S1: material selection, the ingredients of the low-sugar and low-salt Dongpo lychee cookies are as follows: 180 parts of Hefeng cream, 200 parts of ghee, 240 parts of powdered sugar, 2 parts of salt, 160 parts of milk, and 556 parts of low flour , 33 parts of milk powder, 22 parts of custard powder, 160 parts of dried lychee;

[0054] S2: Material preparation, put 160 parts of dried lychees obtained according to S1 into a heater for heating at medium temperature for 4 minutes, put 160 parts of dried lychees after heating on the top of the cutting board, and chop 160 parts of dried lychees with a knife 160 parts of milk obtained according to S1 are put into a container, and 160 parts of chopped lychee are put into 160 parts of milk for soaking;

[0055] S3: Mix the materials. According to S1, put 180 parts of Hefeng butter, 200 parts of ghee, 240...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com