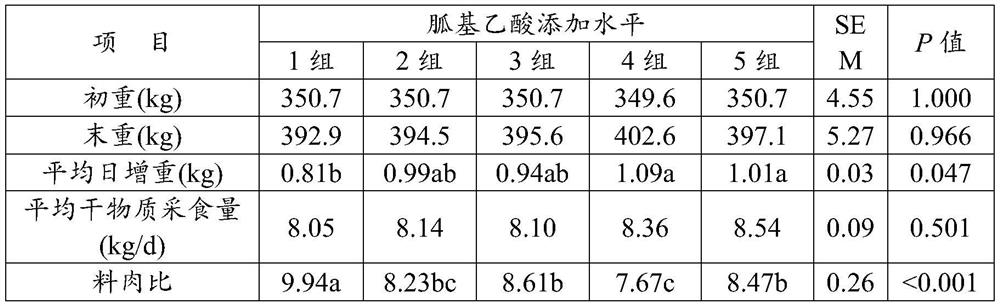

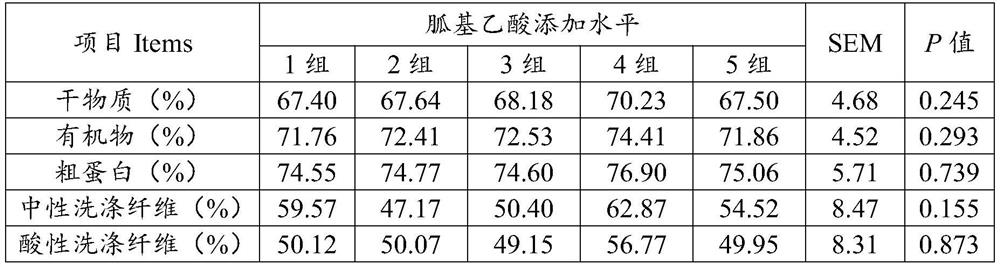

Application of guanidinoacetic acid in improving production performance, slaughter performance and meat quality of beef cattle

A technology of guanidinoacetic acid and production performance, which is applied to slaughter performance and meat quality. Guanidinoacetic acid can solve the problems of unknown production performance of beef cattle in the field of improving beef cattle production performance, so as to improve the body's antioxidant capacity and reduce dripping water. Loss, the effect of improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 2.5g guanidinoacetic acid is stirred evenly with the concentrated material fed with every meal of every beef cattle to obtain mixed concentrated material; the daily consumption of concentrated material is 1.5% of the beef cattle body weight; wherein the concentrated material is made of the following raw materials by weight percentage Composition: 60% corn, 10% wheat bran, 25% soybean meal, 1% calcium bicarbonate, 4% premix; the premix contains: 150000IU per kilogram of premix: vitamin A150000IU, vitamin D320000IU, vitamin E3000IU , Fe 3200mg, Mn 1500mg, Zn 2000mg, Cu650mg, I 35mg, Se 10mg, Co 10mg, Ca 130g, P 30g;

[0033] (2) Beef cattle are first fed with the mixed concentrate obtained in step (1) at each meal, and then fed with coarse material. The mass ratio of the dry matter of the mixed concentrate to the coarse material is 4:6; they are fed twice a day; the coarse material is Elephant grass silage, the preparation method of elephant grass silage is: mowing el...

Embodiment 2

[0035] (1) 5g guanidinoacetic acid is stirred evenly with the concentrate fed with every meal of each beef cattle to obtain a mixed concentrate; the daily consumption of the concentrate is 1.5% of the beef cattle body weight; wherein the concentrate consists of the following raw materials by weight percentage 60% of corn, 10% of wheat bran, 25% of soybean meal, 1% of calcium bicarbonate, 4% of premix; the premix contains: vitamin A150000IU per kilogram, vitamin D320000IU, vitamin E 3000IU, Fe 3200mg, Mn 1500mg, Zn 2000mg, Cu650mg, I 35mg, Se 10mg, Co 1mg, Ca 130g, P 30g;

[0036] Beef cattle are first fed with the mixed concentrate obtained in step (1) for each meal, and then fed with coarse material, the mass ratio of dry matter between the mixed concentrated material and coarse material is 4:6; they are fed twice a day; the coarse material is elephant grass silage Feed, the preparation method of elephant grass silage is identical with embodiment 1.

Embodiment 3

[0038] (1) Stir 10g of guanidinoacetic acid with the concentrate fed with every meal of each beef cattle to obtain a mixed concentrate; the daily consumption of the concentrate is 1.5% of the body weight of the beef cattle; wherein the concentrate consists of the following raw materials by weight percentage 60% of corn, 10% of wheat bran, 25% of soybean meal, 1% of calcium bicarbonate, 4% of premix; the premix contains: vitamin A150000IU per kilogram, vitamin D320000IU, vitamin E 3000IU, Fe 3200mg, Mn 1500mg, Zn 2000mg, Cu650mg, I 35mg, Se 10mg, Co 10mg, Ca 130g, P 30g;

[0039] Beef cattle are first fed with the mixed concentrate obtained in step (1) for each meal, and then fed with coarse material, the mass ratio of dry matter between the mixed concentrated material and coarse material is 4:6; they are fed twice a day; the coarse material is elephant grass silage Feed, the preparation method of elephant grass silage is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com