Vegetable drying equipment

A technology for drying equipment and vegetables, applied in lighting and heating equipment, conveyor objects, furnaces, etc., can solve the problems of poor drying effect of vegetables, improve drying effect, promote water evaporation, increase elasticity and ductility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

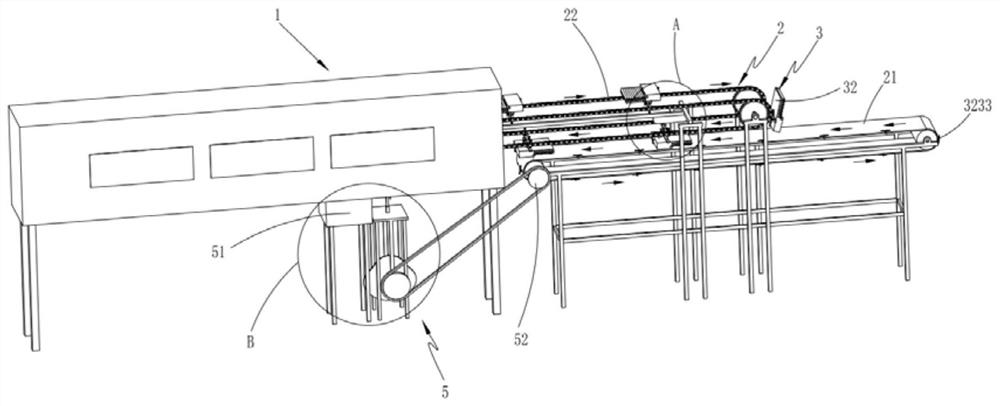

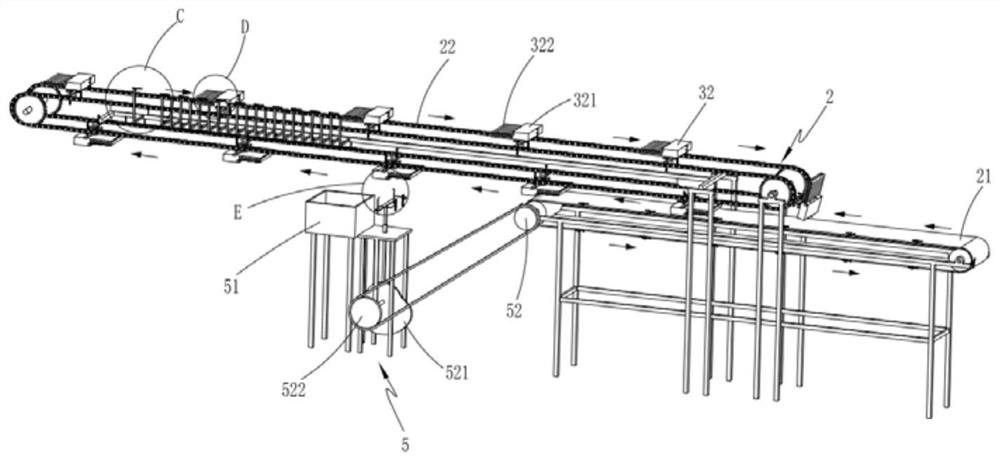

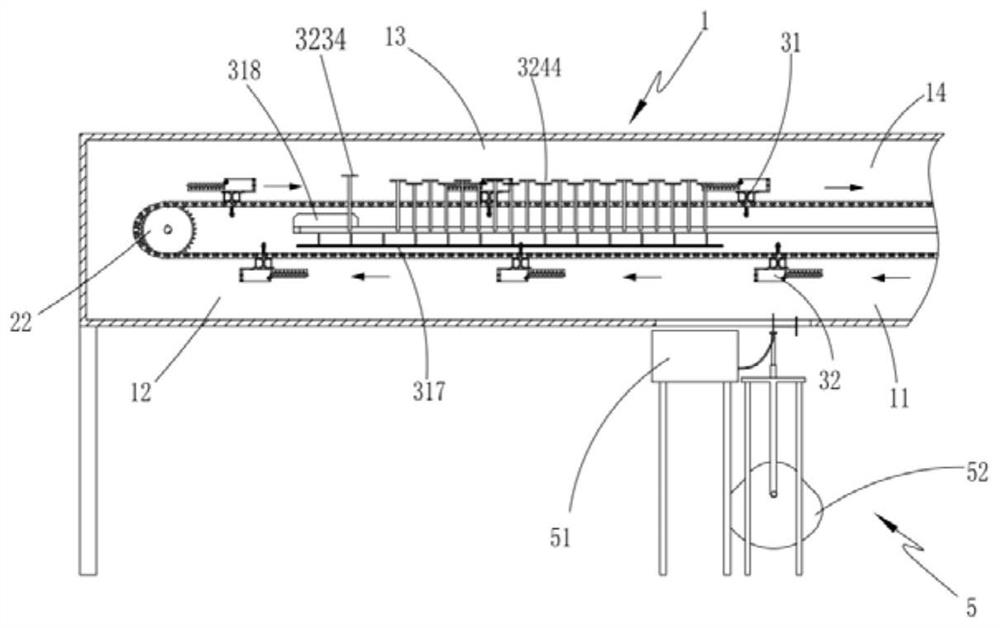

[0050] Such as Figure 1 to Figure 3 Shown, a kind of vegetable drying equipment comprises:

[0051] An oven 1, the oven 1 includes a preheating zone 11, a drying zone a12, a drying zone b13 and a cooling zone 14;

[0052] The conveying device 2, the conveying device 2 includes a conveying assembly a21 installed on one side of the oven 1 and arranged in a rotary manner, and is erected above the conveying belt assembly a21 and passes through the preheating zone 11, the The drying area a12, the drying area b13 and the conveying assembly b22 of the cooling area 14;

[0053] The reclaiming device 3, the reclaiming device 3 includes several sets of mounting assemblies 31 distributed on the rotary path array along the conveying assembly b22 and capable of rotating and moving up and down, and correspondingly installed below the mounting assemblies 31 and A material receiving assembly 32 that follows the movement of the installation assembly 31;

[0054] The material receiving asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com