Separation method of pyrite and pyrrhotite

A pyrrhotite and separation method technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem of inability to achieve effective separation of pyrite and pyrrhotite, and inability to obtain high-grade pyrite concentrate Mining and other problems, to achieve the effect of reducing floatability and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

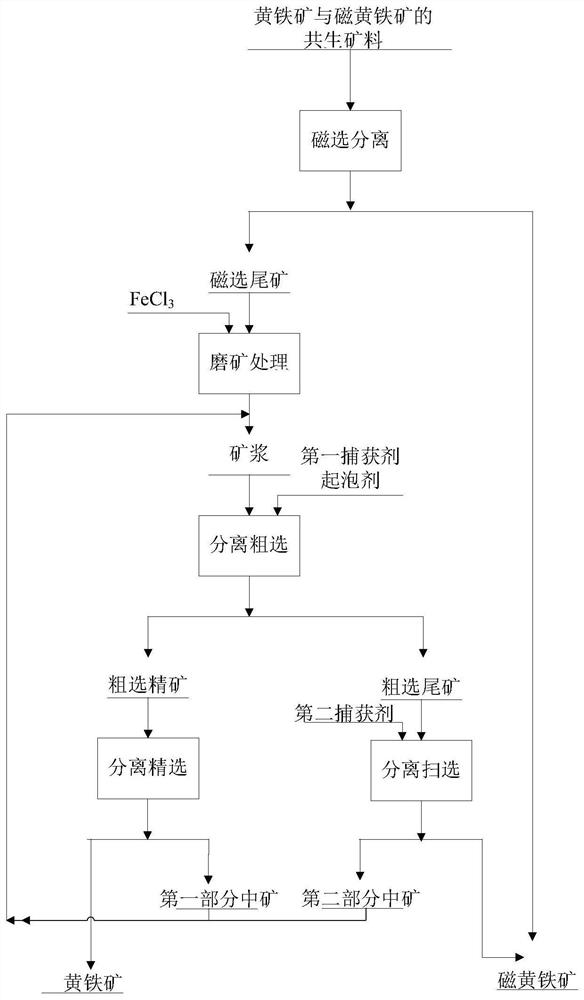

Method used

Image

Examples

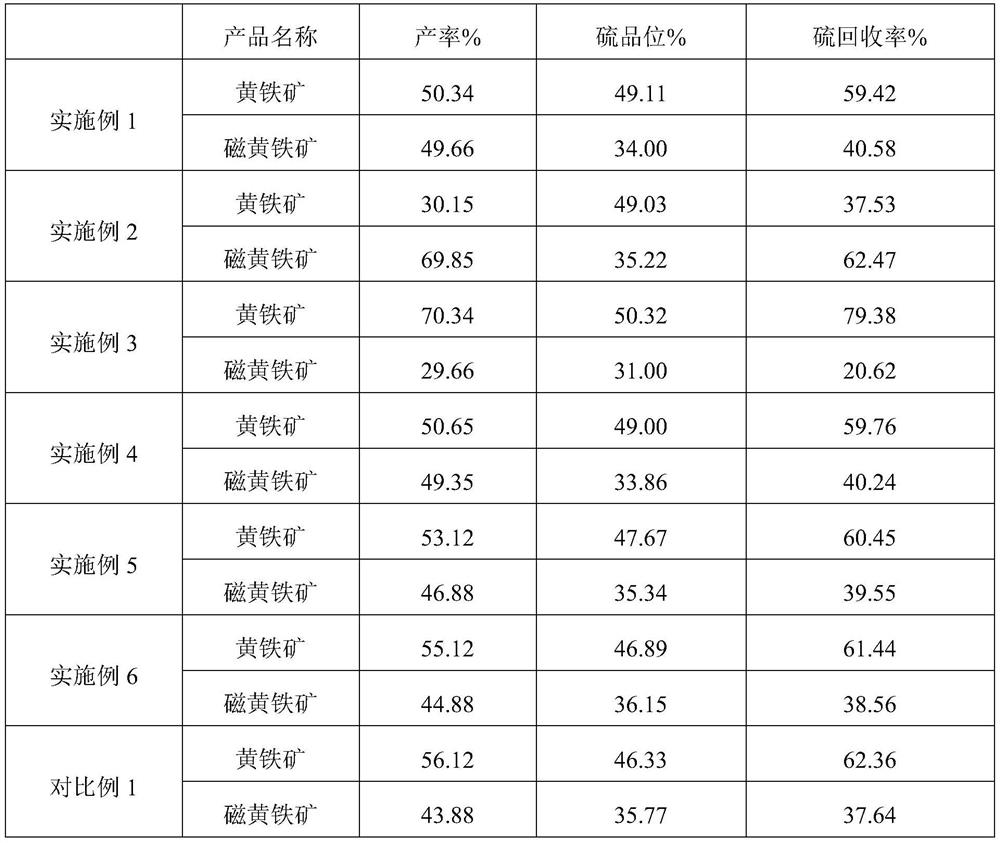

Embodiment 1

[0035] This example is the sulfur concentrate obtained by flotation in a lead-zinc-sulfur separation plant. Gangue minerals such as silicate and quartz. Among them, the pyrite content is 45%, the pyrrhotite content is 50%, and the sulfur grade is 41.61%.

[0036] The symbiotic ore of pyrite and pyrrhotite is first separated by magnetic separation to obtain magnetic separation concentrate and magnetic separation tailings, wherein the magnetic field strength is 3500Oe, and the magnetic separation concentrate is the first part of pyrrhotite.

[0037] The magnetic separation tailings and FeCl 3 Mixing and grinding treatment, wherein, the grinding concentration is 65%, relative to each ton of magnetic separation tailings, FeCl 3 The dosage is 150g, the grinding fineness is 91.22% of ore grains with particle size less than 0.045mm, the grinding medium is iron medium, and the grinding time is 10min.

[0038] The pulp, dixanthate and No. 2 oil are mixed and subjected to separation ...

Embodiment 2

[0042] This example is a sulfur concentrate obtained by sequentially flotation zinc and sulfur in a high-sulfur copper-lead-zinc ore using a copper-lead mixed flotation process. The main mineral in the obtained sulfur concentrate is pyrrhotite, and its content is 75%. Followed by pyrite, its content is 21%, and the rest are gangue minerals such as quartz, feldspar and dolomite. In particular, the pyrrhotite content of the sulfur concentrate is relatively high, and the sulfur grade of the sulfur concentrate is only 39.38%.

[0043] The symbiotic ore of pyrite and pyrrhotite is first separated by magnetic separation to obtain magnetic separation concentrate and magnetic separation tailings, wherein the magnetic field strength is 4000Oe, and the magnetic separation concentrate is the first part of pyrrhotite.

[0044] The magnetic separation tailings and FeCl 3 Mixing and grinding treatment, wherein, the grinding concentration is 65%, relative to each ton of magnetic separation ...

Embodiment 3

[0049] This example is a sulfur concentrate obtained by using copper priority flotation and copper flotation tailings sulfur separation in a copper-sulfur ore. The main mineral in the sulfur concentrate is pyrite, with a content of 70.5%, followed by pyrrhotite ore, its content is 26%, the rest is gangue minerals such as quartz, the sulfur grade of this sulfur concentrate is 44.59%.

[0050] The symbiotic ore of pyrite and pyrrhotite is first separated by magnetic separation to obtain magnetic separation concentrate and magnetic separation tailings, wherein the magnetic field strength is 3000Oe, and the magnetic separation concentrate is the first part of pyrrhotite.

[0051] The magnetic separation tailings and FeCl 3 Mixing and grinding treatment, wherein, the grinding concentration is 65%, relative to each ton of magnetic separation tailings, FeCl 3 The dosage is 100g, the grinding fineness is 91.11% of ore grains with particle size less than 0.045mm, the grinding medium i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap