Non-sputtering precise painting method and painting system

A precise and sputtering technology, applied in spray booths, spraying devices, electrostatic spraying devices, etc., can solve problems such as inclusions and poor film surface quality, achieve high density, avoid insufficient preheating and curing, and compact system structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

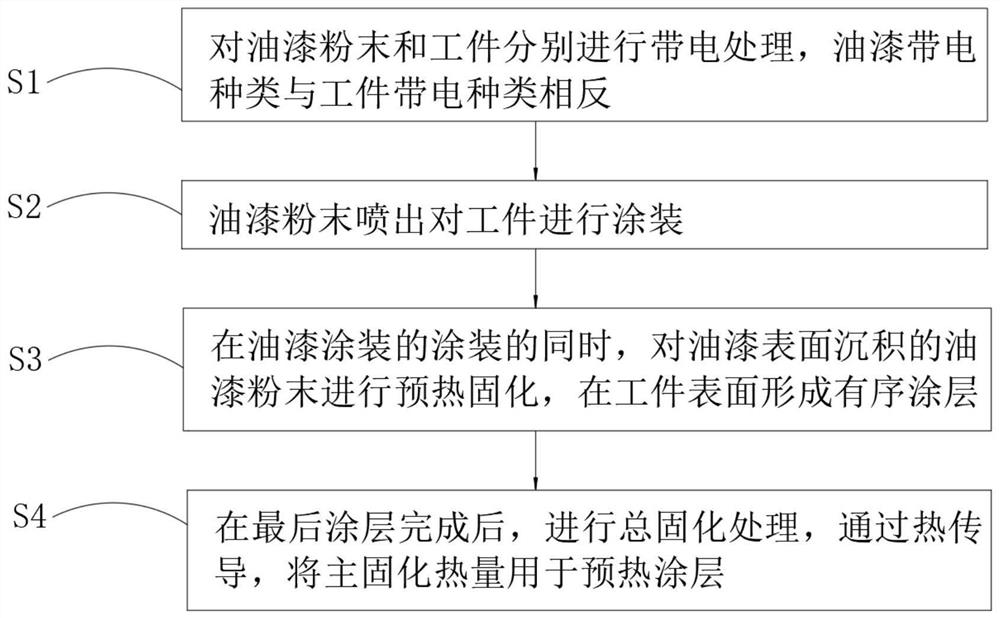

[0036] refer to figure 1 , a non-sputtering precision painting method, comprising the following steps:

[0037] S1: Carry out electrification treatment on the paint powder and the workpiece, and keep the electrification type of the paint opposite to the electrification type of the workpiece;

[0038] S2: the paint powder is sprayed out to coat the workpiece;

[0039] S3: while the paint coating is being applied, the paint powder deposited on the paint surface is preheated and solidified to form an orderly coating on the surface of the workpiece;

[0040] S4: After the final coating is completed, the main curing treatment is carried out, and the total curing heat is used for preheating the coating through heat conduction.

[0041] The method in this embodiment preheats and solidifies the deposited paint powder, so that individual coatings on the surface of the workpiece are formed one by one. When a single coating is formed, because its thickness is relatively thin, the gas h...

Embodiment 2

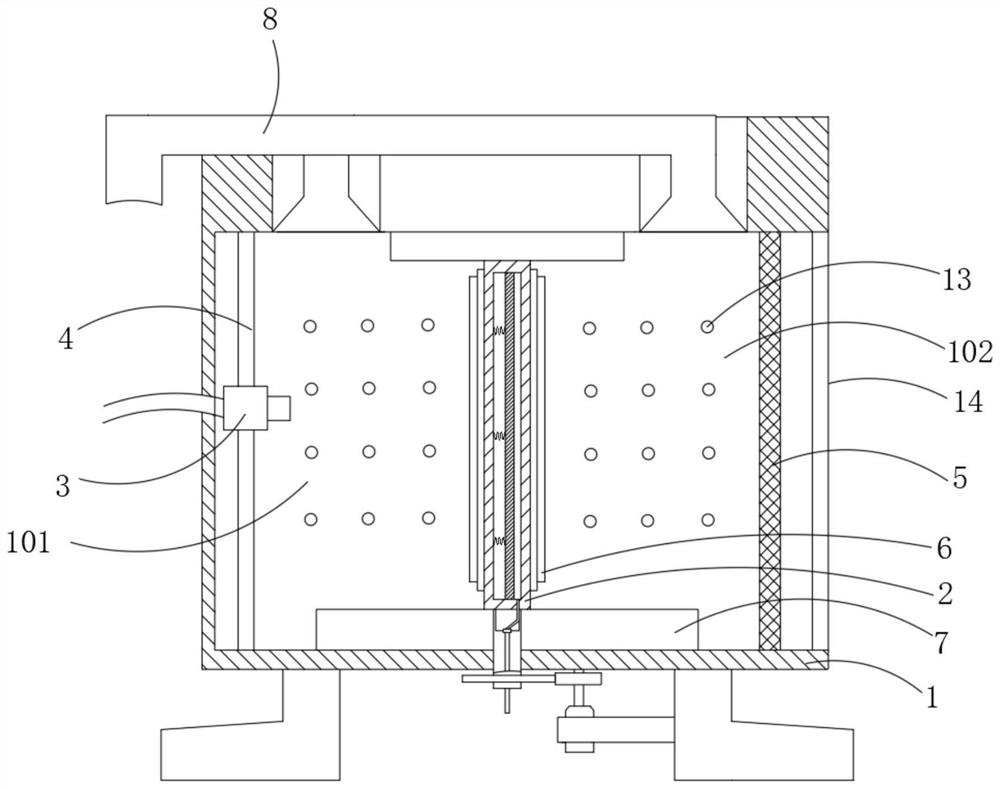

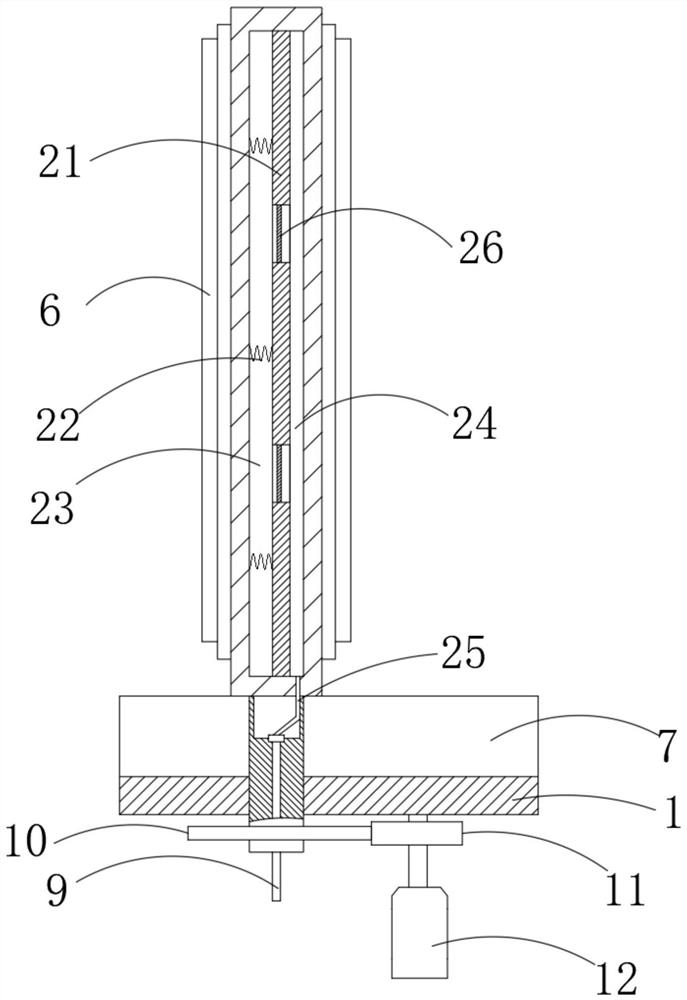

[0043] A non-sputtering precision painting system is disclosed in this embodiment. The painting system includes a painting platform 1, a loading plate 2 connected in rotation with the frame, a spray gun 3 and a heating plate 5. The painting platform 1 is provided with Working chamber, the working chamber of the working chamber coating platform 1 is divided into a spraying chamber 101 and a curing chamber 102 by the object carrier plate 2, and the sides corresponding to the object carrier plate 2 and the spray gun 3 or the heating plate 5 are respectively arranged for Mount the workpiece holder 6.

[0044] Further, the spray gun 3 and the mobile bracket 4 provided inside the spray chamber 101, the spray gun 3 is installed on the mobile bracket 4, the mobile bracket 4 can move inside the spray chamber 101, adjust the distance between the spray gun 3 and the workpiece, and improve the system suitability.

[0045] The nozzle of the spray gun 3 applies a high-voltage negative voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com