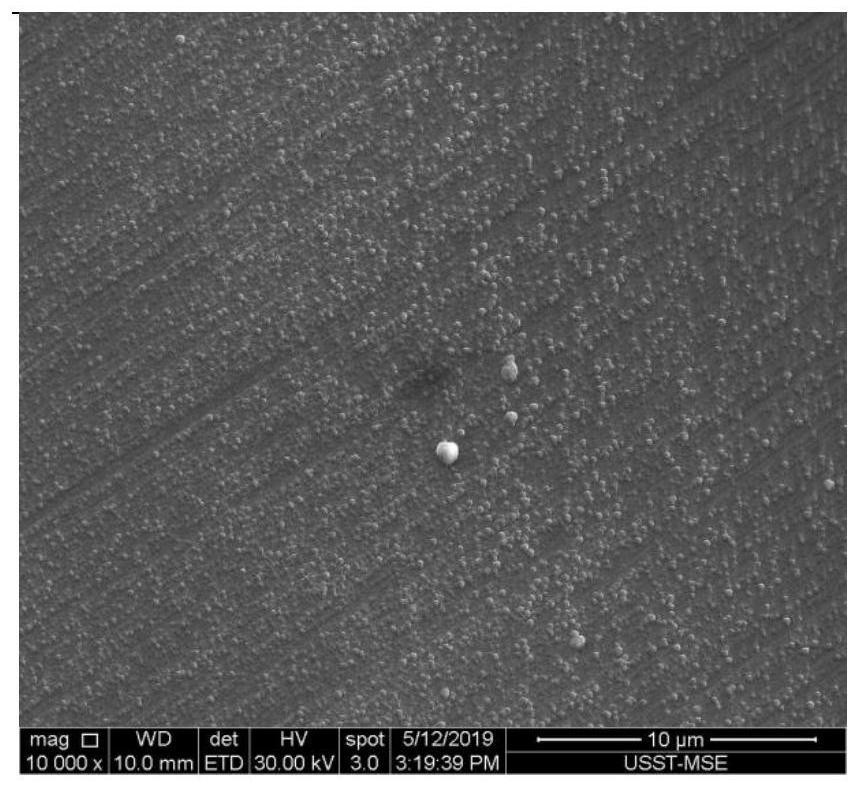

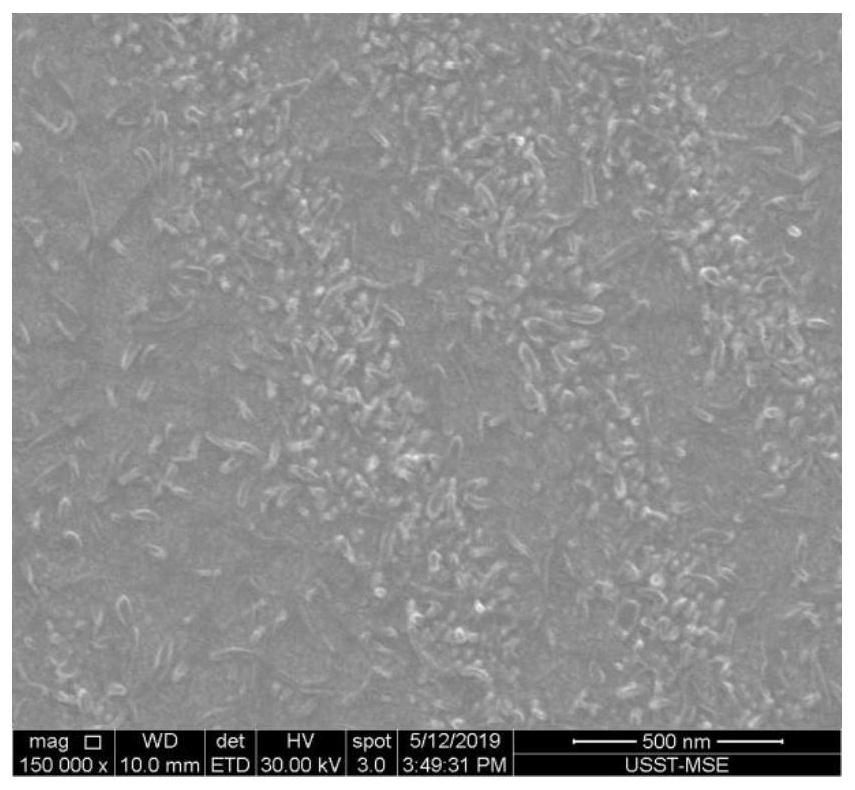

Preparation method of copper nanosphere particles with continuously adjustable size

A technology of spheres and metal nano-particles, which is applied in the field of continuously adjustable metal nano-spheres, can solve the problems of time-consuming, cumbersome preparation process, and the inability to control the continuous adjustment of particle size, so as to achieve the operation process Simple, simple preparation process, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0022] (1) Use a diamond pen to cut the substrate (such as a silicon wafer) into 10 parts with a size of about 3mm×3mm.

[0023] (2) On the heater, stick the cut silicon chip on the copper block with paraffin, and extend the excessively long part out of the copper block. After cooling, use 1200-grit sandpaper to grind off the excessively long part of the silicon wafer to make a square silicon wafer with a size of about 2mmX2mm, ensuring that the central hollow ring of the gold and copper rings can be covered without exceeding the gold and copper rings range. Repeat this operation for the other 9 silicon wafers.

[0024] (3) Glue the obtained 2mm×2mm silicon wafer on the transparent cylinder with paraffin wax, put the transparent cylinder into a disk mill, and then calibrate it. Using 1200 grit sandpaper, subtract 200µm in thickness.

[0025] (4) Glue the reduced-thickness silicon wafer on the right-angle frame with paraffin, install the right-angle frame back to the Tripod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com