A vortex beam generation system, method and phase modulation combination device

A phase modulation and combination device technology, applied in the field of laser applications, can solve the problems of inability to flexibly meet processing requirements, inability to withstand kilowatt-level lasers, lack of flexibility and convenience, and achieve continuously adjustable size, long focal depth, and anti-misalignment. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

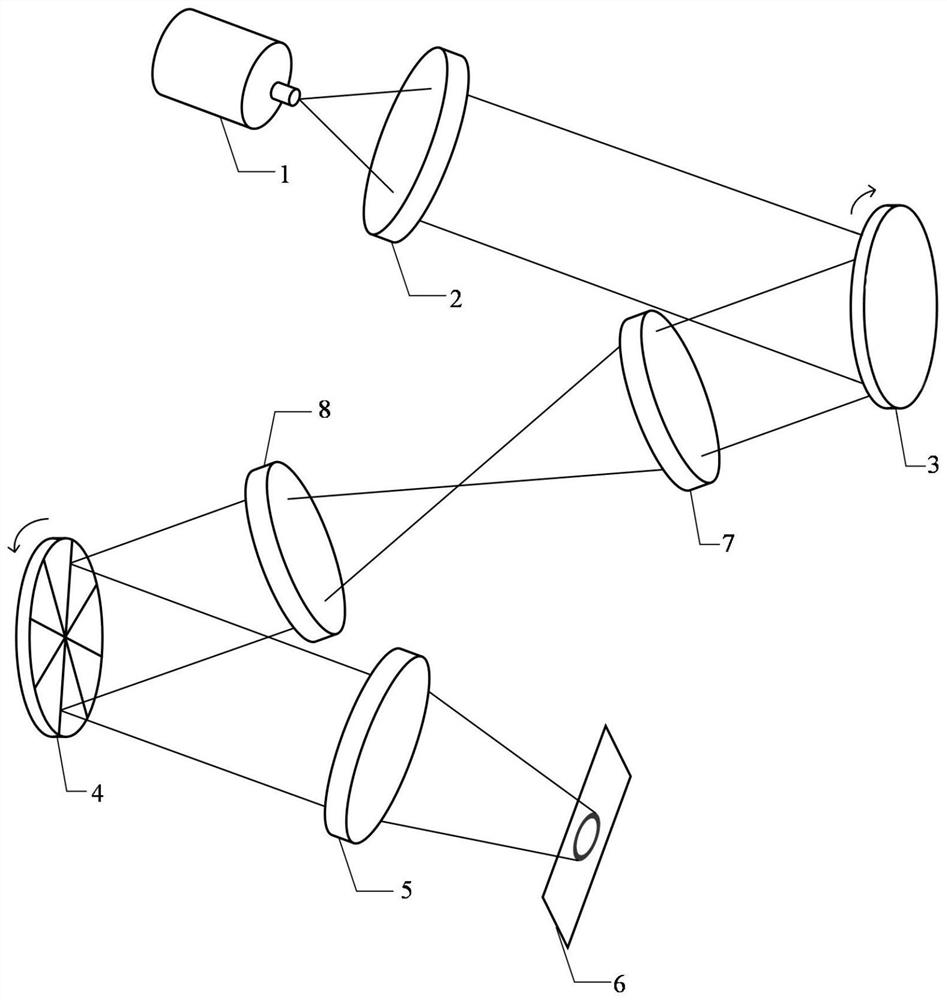

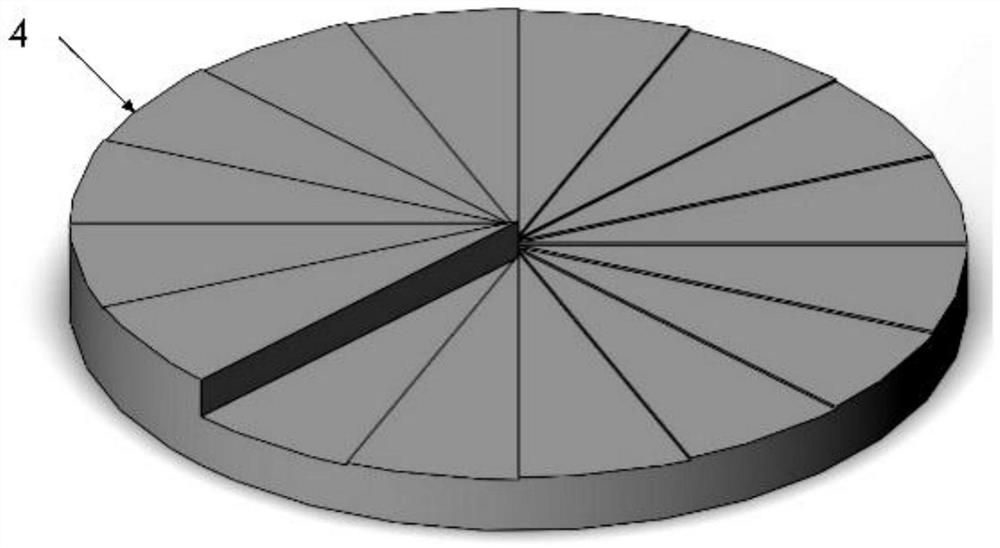

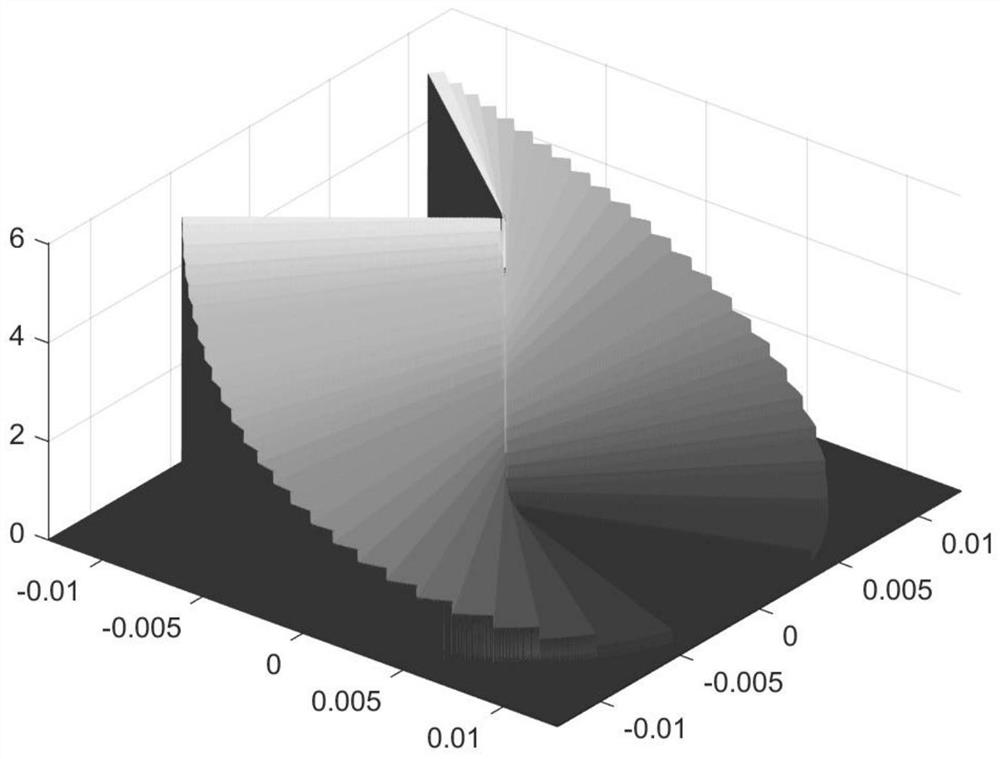

[0043] see figure 1 and figure 2 , this embodiment discloses a phase modulation combination device, including two helical-specific reflective spiral phase mirrors, and the phases of the two reflective spiral phase mirrors are respectively set to Aθ 2 and -Aθ 2 , A is a constant, which is used to control the variation range of the topological number of the obtained vortex beam. The topological number of the obtained vortex light takes all integers in the interval from 0 to 4Aπ, and θ is the azimuth angle with the center of the reflective spiral phase mirror as the origin , two reflective spiral phase mirrors are set on the optical path, the laser beam is reflected by the two reflective spiral phase mirrors in turn, and then the laser beam is attached with a spiral phase factor with a set topological number, and becomes an annular vortex beam with adjustable radius. The topological number of the resulting vortex beam is tuned by rotating one or both reflective spiral phase mi...

Embodiment 2

[0062] see figure 1 , this embodiment discloses a vortex beam generation system, including a collimation unit 2, a focusing unit 5, and the phase modulation combination device described in Embodiment 1, the phase modulation combination device is arranged between the collimation unit 2 and the focus unit on the optical path between 5;

[0063] The collimation unit 2 is used to collimate the input laser to obtain a collimated laser beam;

[0064] The two reflective spiral phase mirrors of the phase modulation combination device are used to sequentially reflect the collimated laser beam emitted by the collimation unit, and then attach a spiral phase factor with a set topological number, so that the laser beam becomes a radius-adjustable ring vortex beam;

[0065] The focusing unit 5 is used to focus the ring-shaped light beam emitted by the phase modulation combination device to obtain a light spot with ring-shaped energy distribution.

[0066] Further, before the collimation ...

Embodiment 3

[0074] This embodiment discloses a method for generating a vortex beam. The vortex beam generating system described in Embodiment 2 is adopted. The method includes the following steps: the laser emits a laser with a Gaussian distribution of light intensity, and the beam passes through a collimation unit for collimation. Straight processing to obtain a collimated laser beam;

[0075] The initial positions of the two reflective spiral phase mirrors of the phase modulation combination device are aligned. At this time, the phase modulation combination device has no phase modulation effect on the laser beam. Rotate one or two of the reflective spiral phase mirrors to adjust the resulting vortex beam. topological number, the angular difference between the two reflective spiral phase mirrors must be Integer multiples of , when the angle difference between the two reflective spiral phase mirrors is , the laser beam is sequentially reflected by two reflective spiral phase mirrors, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com