Industrial robot shell manufacturing method

A technology of industrial robots and production methods, applied in the field of industrial robot shell production, to achieve the effects of simple structure, positive social value and economic value, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

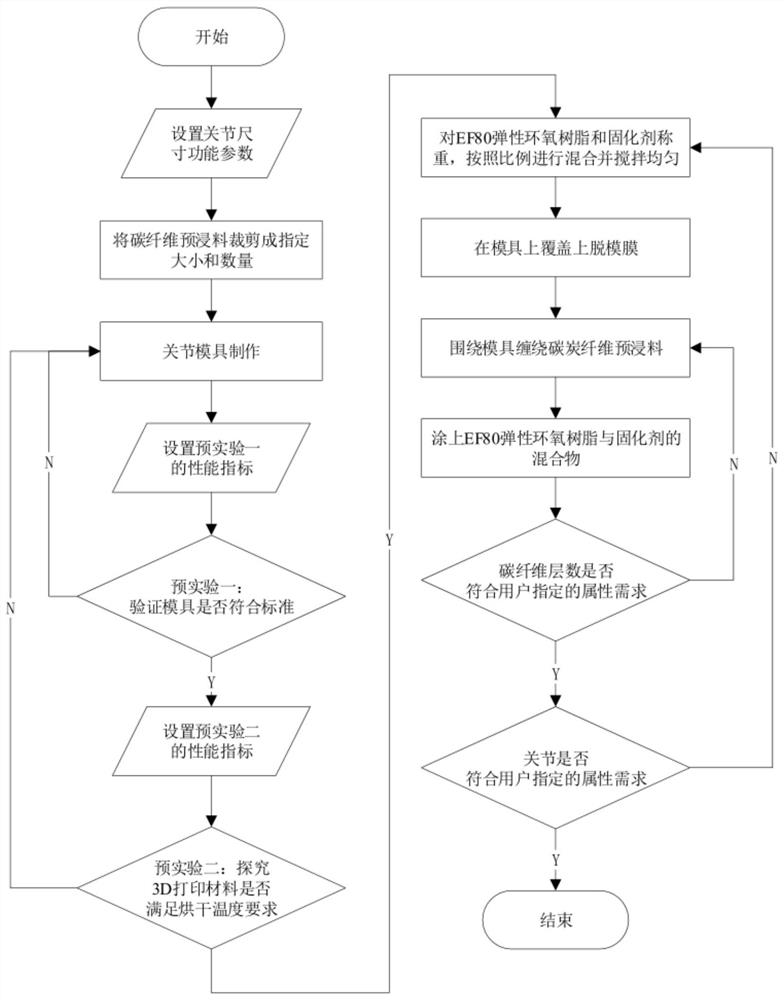

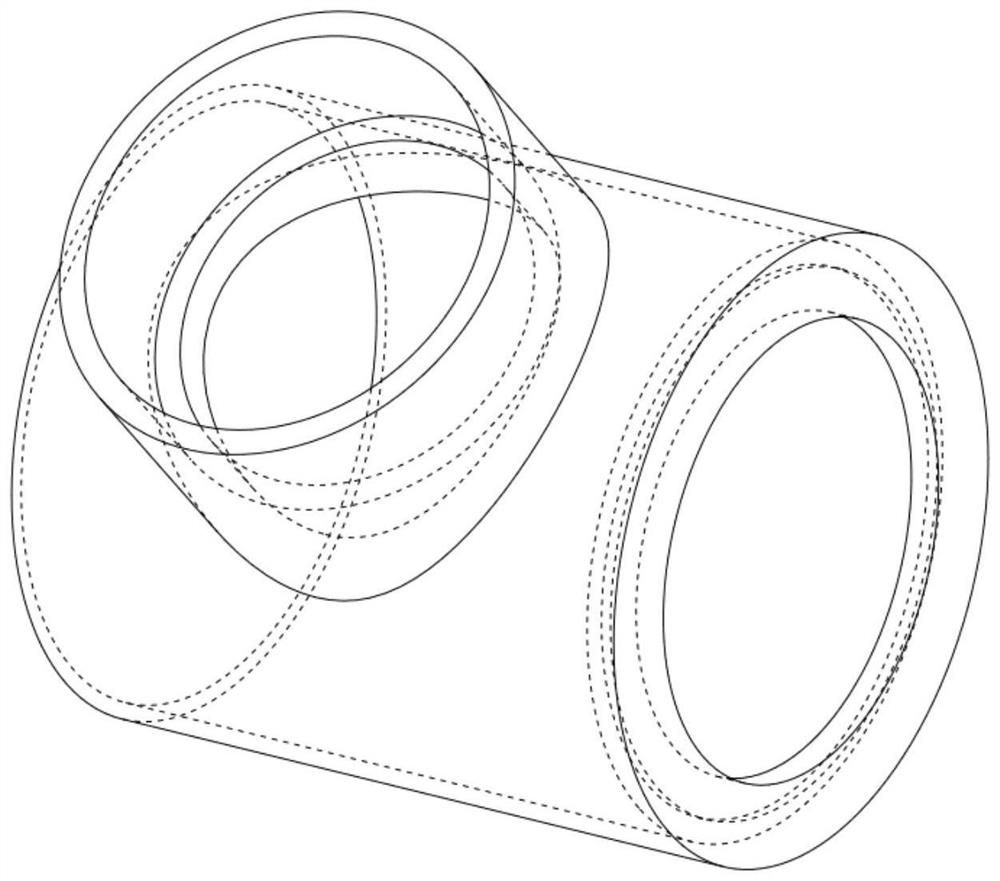

[0036] Set the functional parameters of the joint shell size of the industrial robot, such as image 3 As shown; cut the carbon fiber prepreg into the specified size and quantity; make the shell mold: use the simulation software to design the mold required for the target shell, including: inner core tube wall, side tube wall, end face cover, outer left The side pipe wall and the outer right pipe wall, in which the inner core pipe wall and the side pipe wall are closed, not through pipes, such as Figure 5 As shown; set the performance index of the pre-experiment 1; through the pre-experiment 1, judge whether the mold meets the standard, and use ABS material to print the mold; set the performance index of the pre-experiment 2, and judge whether the mold meets the requirements of the manufacturing process conditions, that is, whether deformation occurs; Through the second pre-experiment, set the drying temperature of the carbon fiber material according to the melting point and g...

Embodiment 2

[0038]Set the functional parameters of the joint shell size of the industrial robot; cut the carbon fiber prepreg into the specified size and quantity; make the shell mold: use the simulation software to design the mold required for the target shell, including: inner core tube wall, side tube wall , the end cover, the outer left pipe wall and the outer right pipe wall, in which the inner core pipe wall and the side pipe wall are closed, not through pipes; set the performance index of the pre-experiment 1; through the pre-experiment 1, determine whether the mold is According to the standard, use the PLA material to print the mold; set the performance index of the pre-experiment 2 to judge whether the mold meets the requirements of the manufacturing process conditions, that is, whether there is deformation; pass the pre-experiment 2, according to the melting point and glass transition of the PLA material used to make the mold The temperature parameter is used to set the drying te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com