Oil-water separation device based on application of machining center

A technology for oil-water separation device and processing center, which is applied in separation methods, liquid separation, grease/oily substance/float removal devices, etc., and can solve the problems of difficult separation, low efficiency, and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

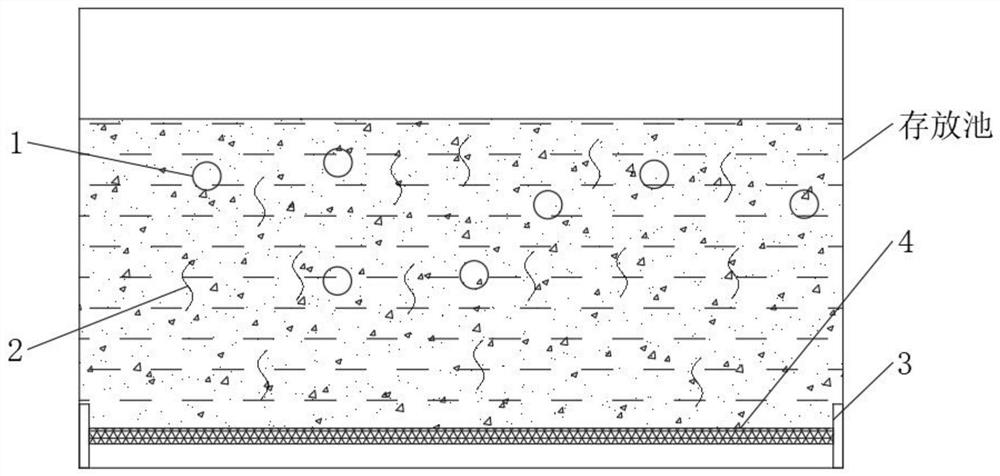

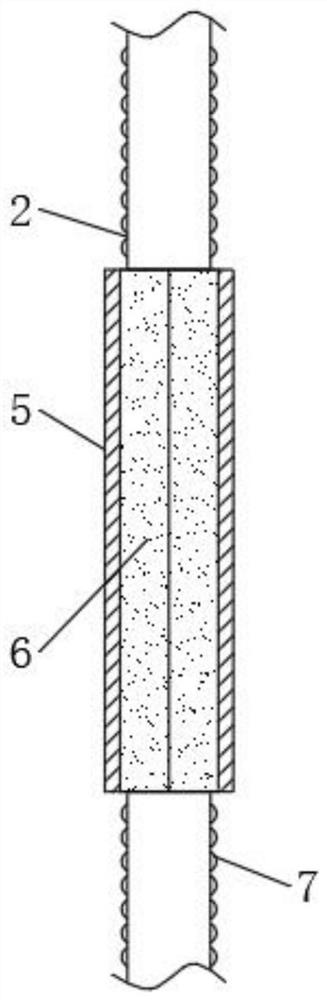

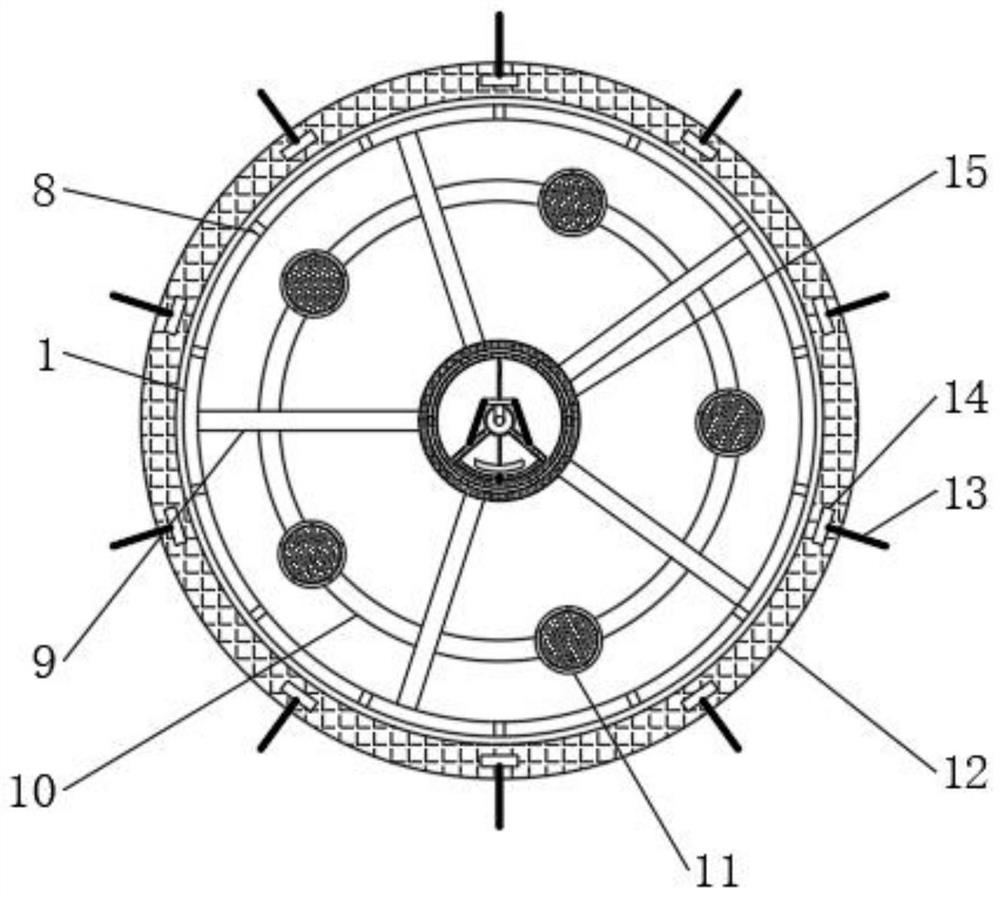

[0044] see Figure 1-3 with Image 6 , an oil-water separation device based on the application of a machining center, including a storage pool containing adsorption balls 1 and lipophilic fibers 2, a pair of support plates 3 are fixedly connected to the inner wall of the storage pool, and an electromagnetic net 4 is fixedly connected between the pair of support plates 3 , the inside of the electromagnetic network 4 is equipped with a heating wire 27, and the inside of the adsorption ball 1 is provided with a magnetic levitation device, and a plurality of evenly distributed connecting rods 9 are fixedly connected between the magnetic levitation device and the adsorption ball 1. A fixed ring 10 is fixedly connected between them, the outer end of the fixed ring 10 is fixedly connected with a sterilizing ball 11, the inside of the sterilizing ball 11 is filled with antibacterial fibers, and the outer end of the adsorption ball 1 is dug with a plurality of evenly distributed throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com