A preparation method of organic tungsten catalyst for polydicyclopentadiene composite material injection molding

A technology of polydicyclopentadiene and composite materials, applied in the fields of organic chemistry, chemical instruments and methods, metallocene, etc., can solve the problem of unsatisfactory catalytic effect, general stability, impurity tolerance, poor miscibility and dispersibility and other problems to achieve the effect of improving miscibility and dispersion uniformity, reducing layered accumulation, reducing specific gravity and polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

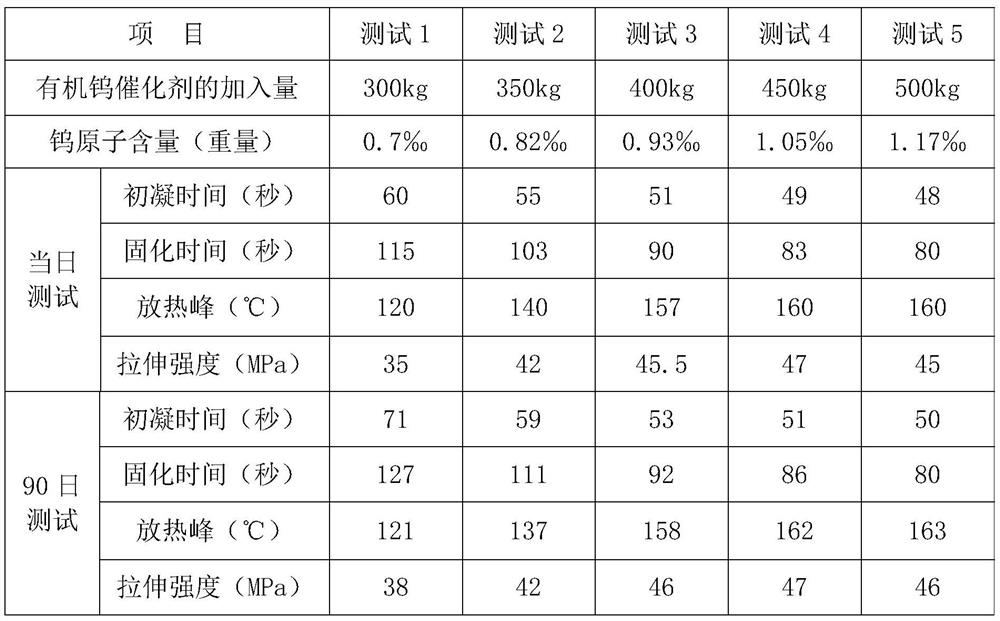

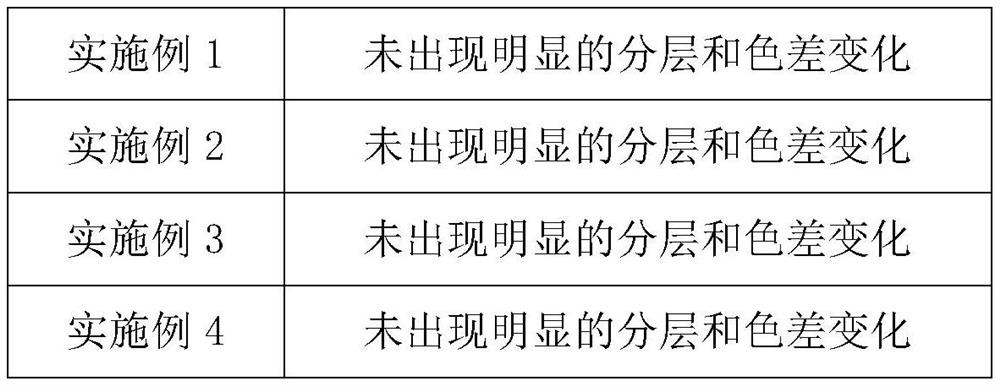

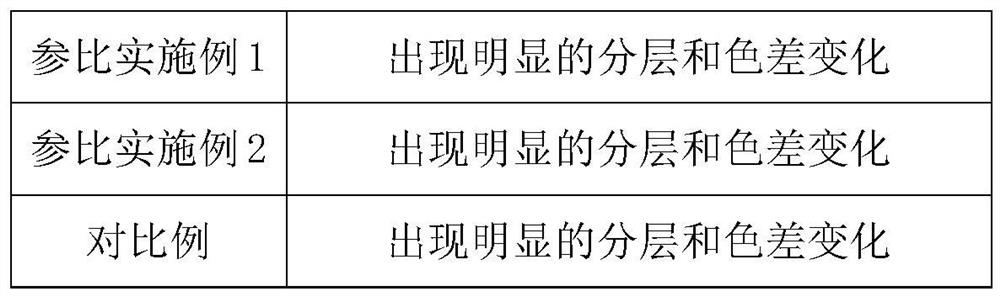

Examples

Embodiment 1

[0043] The organic tungsten catalyst for injection molding of polydicyclopentadiene composites was prepared according to the following steps:

[0044]S1. In the reactor with heating device and stirring device, the volume is 3000L, feed nitrogen to replace the air 3 times, then add 200kg BHT polymerization inhibitor into the reactor;

[0045] S2. Pump 2400L dicyclopentadiene into the reactor, stir until evenly mixed, and then feed nitrogen into the reactor to replace the air for 3 times;

[0046] S3. Under the condition of isolated air, add 6kg of platinum carbon into the reaction kettle, stir until the dispersion is uniform;

[0047] S4. Turn on the heating device of the reactor, and heat the temperature of the reactor to 140° C.;

[0048] S5. Introduce nitrogen into the evaporating tank with a heating device and a volume of 300L to replace the air for 3 times, then add 300kg of tungsten hexachloride into the evaporating tank, turn on the heating device of the evaporating tan...

Embodiment 2

[0052] The organic tungsten catalyst for injection molding of polydicyclopentadiene composites was prepared according to the following steps:

[0053] S1. In the reactor with heating device and stirring device, the volume is 3000L, feed nitrogen to replace the air 3 times, then add 200kg BHT polymerization inhibitor into the reactor;

[0054] S2. Pump 2400L dicyclopentadiene into the reactor, stir until evenly mixed, and then feed nitrogen into the reactor to replace the air for 3 times;

[0055] S3. under the condition of isolated air, add 2kg of palladium charcoal into the reaction kettle, stir until uniformly dispersed;

[0056] S4. Turn on the heating device of the reactor, and heat the temperature of the reactor to 110° C.;

[0057] S5. Introduce nitrogen into the evaporating tank with a heating device and a volume of 300L to replace the air for 3 times, then add 300kg of tungsten hexachloride into the evaporating tank, turn on the heating device of the evaporating tank,...

Embodiment 3

[0061] The organic tungsten catalyst for injection molding of polydicyclopentadiene composites was prepared according to the following steps:

[0062] S1. In the reactor with heating device and stirring device, the volume is 3000L, feed nitrogen to replace the air 3 times, then add 200kg BHT polymerization inhibitor into the reactor;

[0063] S2. Pump 2400L dicyclopentadiene into the reactor, stir until evenly mixed, and then feed nitrogen into the reactor to replace the air for 3 times;

[0064] S3. Under the condition of isolated air, add 10kg of platinum carbon into the reaction kettle, stir until it is evenly dispersed;

[0065] S4. Turn on the heating device of the reactor, and heat the temperature of the reactor to 170° C.;

[0066] S5. In the evaporating tank with a heating device and a volume of 300L, feed nitrogen to replace the air 3 times, then add a mixture of 300kg tungsten hexachloride and tungsten oxytetrachloride into the evaporating tank, turn on the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com