Anti-glycation collagen peptide and preparation method thereof

A collagen peptide and collagen technology, applied in the field of anti-glycation collagen peptide and its preparation, can solve the problem of no anti-glycation collagen peptide, etc., and achieve the effects of improving blood vessel elasticity, being easy to digest, and improving skin moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

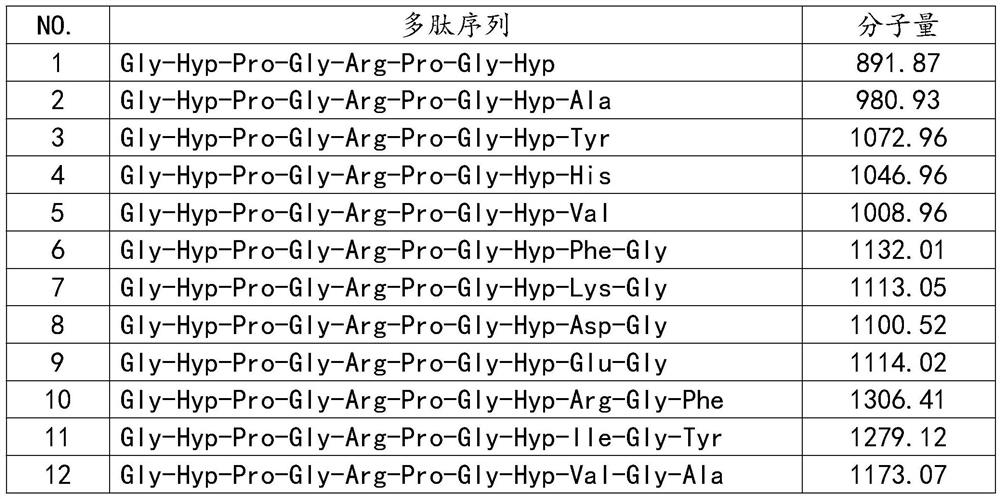

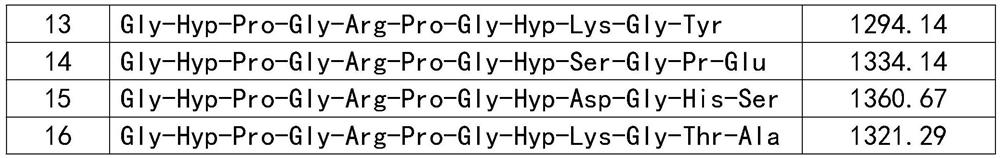

Image

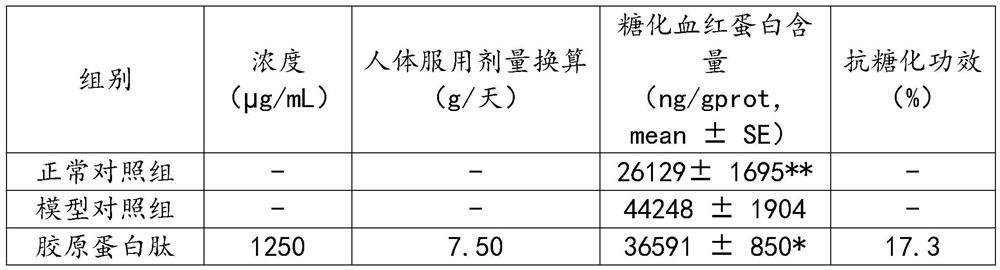

Examples

Embodiment 1

[0025] An anti-glycation collagen peptide made by the following steps:

[0026] Step S1 Preparation of the total protein crude extract: Weigh the raw material, add sodium hydroxide solution to soak for 2 hours, wash twice, add demineralized water, and homogenize in a grinder to a paste to obtain the total protein crude extract;

[0027] Step S2 Preparation of the crude collagen extract: adjust the pH value of the crude total protein extract to 2, heat to 75° C., and keep the gel for 3 hours to obtain the crude collagen extract;

[0028] Step S3 refining of the crude collagen extract: adding a clarifier to the crude collagen extract, adjusting the pH value to 2, stirring evenly and then standing for 2 hours to obtain a refined collagen product;

[0029] Step S4 preparation of collagen peptide: adjust the pH value of the refined collagen to 5, add complex protease for enzymatic hydrolysis, and enzymatically hydrolyze for 2 hours at a temperature of 45° C. to obtain an enzymatic ...

Embodiment 2

[0032] An anti-glycation collagen peptide made by the following steps:

[0033] Step S1 Preparation of the total protein crude extract: Weigh the raw material and add sodium hydroxide solution to soak for 3 hours, wash 3 times, add demineralized water, and homogenize in a grinder to a paste to obtain the total protein crude extract;

[0034] Step S2 Preparation of the crude collagen extract: adjust the pH value of the crude total protein extract to 3, heat to 80° C., and keep the gel for 5 hours to obtain the crude collagen extract;

[0035] Step S3 refining of the crude collagen extract: adding a clarifying agent to the crude collagen extract, adjusting the pH value to 5, stirring evenly and then standing for 5 hours to obtain a refined collagen product;

[0036] Step S4 preparation of collagen peptide: adjust the pH value of the refined collagen to 7, add complex protease for enzymatic hydrolysis, and enzymatically hydrolyze for 4 hours at a temperature of 50° C. to obtain a...

Embodiment 3

[0039] An anti-glycation collagen peptide made by the following steps:

[0040] Step S1 Preparation of the total protein crude extract: Weigh the raw material, add sodium hydroxide solution to soak for 4 hours, wash 3 times, add demineralized water, homogenize in a grinder to a paste, and obtain the total protein crude extract;

[0041] Step S2 Preparation of the crude collagen extract: adjust the pH value of the crude total protein extract to 4, heat to 90° C., and keep the gel for 8 hours to obtain the crude collagen extract;

[0042] Step S3 refining of the crude collagen extract: adding a clarifier to the crude collagen extract, adjusting the pH value to 7, stirring evenly and then standing for 8 hours to obtain a refined collagen product;

[0043] Step S4 preparation of collagen peptide: adjust the pH value of the refined collagen to 8, add complex protease for enzymatic hydrolysis, and enzymolyze for 6 hours at a temperature of 60° C. to obtain an enzymatic hydrolysis so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com