Composite quaternary hydrogel capable of realizing high solar evaporation rate and preparation method thereof

A technology of evaporation rate and hydrogel, which is applied in general water supply saving, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of high-speed evaporation of water, high phase change enthalpy, etc., and achieve excellent light-to-heat conversion ability , enhance energy absorption, reduce the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

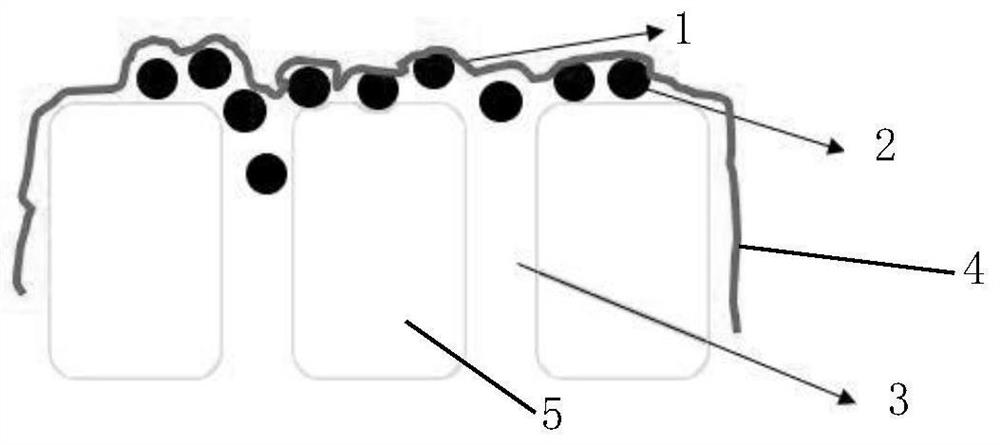

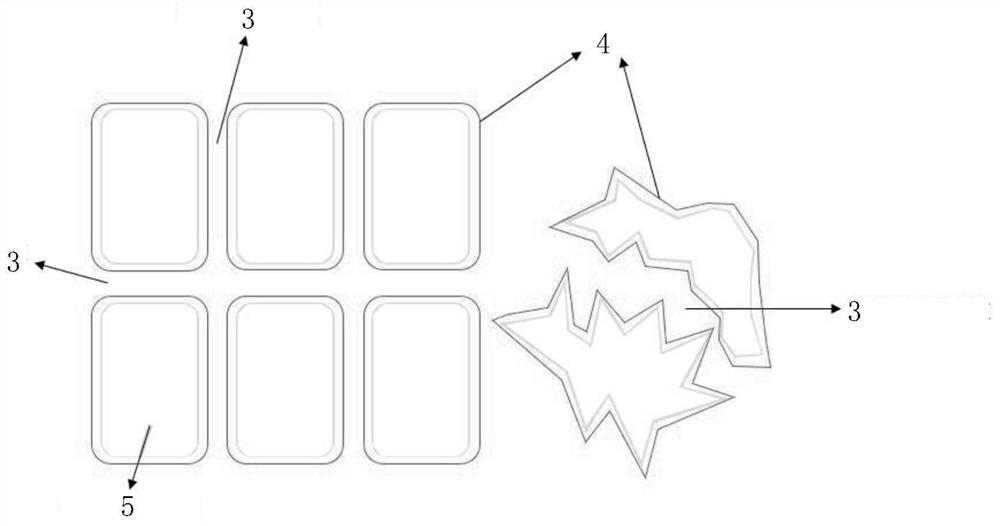

[0036] A composite quaternary hydrogel that can achieve high solar evaporation rates, as figure 1 and figure 2 As shown, the composite quaternary hydrogel is composed of polyvinyl alcohol gel matrix skeleton 5, carbon-based Chinese ink coating and titanium dioxide coating 1; wherein there are multiple gel internal pores 3 inside the polyvinyl alcohol gel matrix skeleton 5 , the carbon-based Chinese ink coating is composed of nanoparticles 2; the lower surface of the carbon-based Chinese ink coating is attached to the upper surface of a polyvinyl alcohol gel matrix skeleton 5, and the upper surface of the carbon-based Chinese ink coating is attached to a conformal titanium dioxide coating 4 On the lower surface, the upper surface of the conformal titanium dioxide coating 4 is attached to the lower surface of the titanium dioxide coating 1; the surface of the internal channel wall of the polyvinyl alcohol gel matrix skeleton 5 is also deposited with a conformal titanium dioxide...

Embodiment 2

[0039] A method for preparing a composite quaternary hydrogel capable of realizing a high solar evaporation rate, comprising the following steps:

[0040] (1) Dissolve the mixture.

[0041] Prepare the gel matrix solution: heat a certain amount of polyvinyl alcohol in distilled water to 80° C. and stir on an electromagnetic stirring table, and prepare an aqueous solution with a mass fraction of 10%. After being completely dissolved, let it stand for 1 hour to eliminate air bubbles to obtain a clear and transparent solution.

[0042] Preparation of polypyrrole suspension: a certain amount of polypyrrole nanoparticles was dispersed in distilled water and ultrasonically oscillated for 20 minutes to prepare a polypyrrole suspension with a mass fraction of 10%.

[0043] Mixing: Mix the polyvinyl alcohol solution and the polypyrrole suspension according to the mass ratio (polyvinyl alcohol: polypyrrole) of 10:1, and stir for a period of time to make the mixture even, and the mixtur...

Embodiment 3

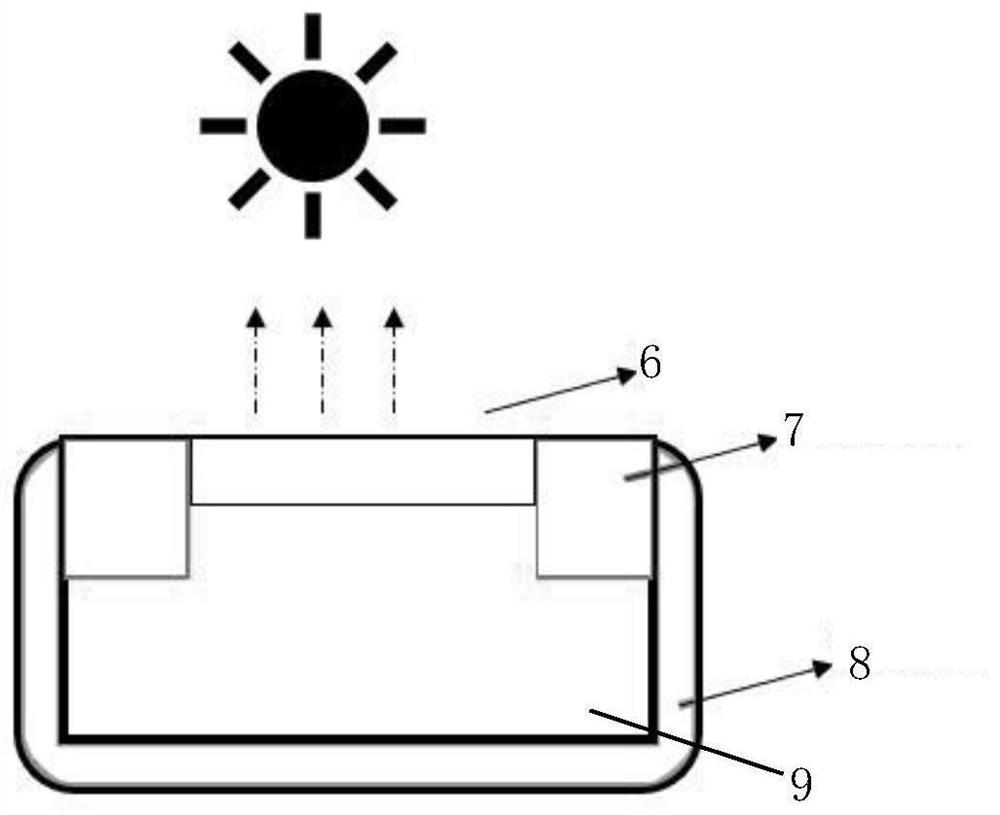

[0059] Such as image 3 As shown, the composite gel prepared in Example 2 is applied to the evaporation system device and the actual application scene to test its evaporation performance:

[0060] Use die cutting to obtain a light receiving area of 4cm 2 The saturated water-containing composite hydrogel (from the composite gel obtained in Example 2) is placed in a foam heat insulating material mold, and the foam heat insulating material is polyethylene white foam, and the vacant area is 4cm 2 . Wrap thermal insulation cotton on the outside of the glass dish to avoid heat conduction loss. The bottom of the composite hydrogel is in contact with water, and the water in the glass dish can be transported vertically and horizontally through the internal pore structure to penetrate into various parts of the composite gel, so sunlight can be absorbed in situ on the surface and inside of the gel for use Evaporate water.

[0061] The experimental results show that at a temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com