Composite foam adhesive and liquid crystal display comprising same

A technology of liquid crystal display and foam glue, which is applied in the direction of instruments, adhesives, film/sheet adhesives, etc., can solve the problems of high cost of lamination tape, high difficulty of lamination detection, and low lamination yield. Achieve the effect of solving fragmentation, suitable for mass industrial production and application, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

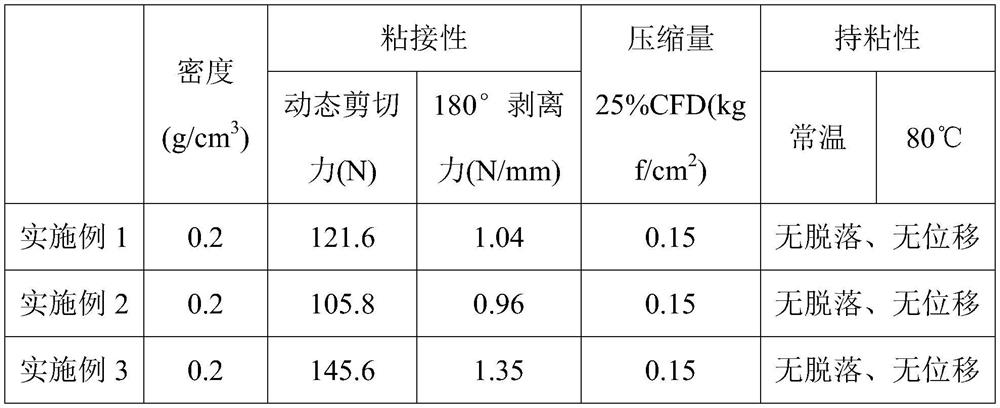

Embodiment 1

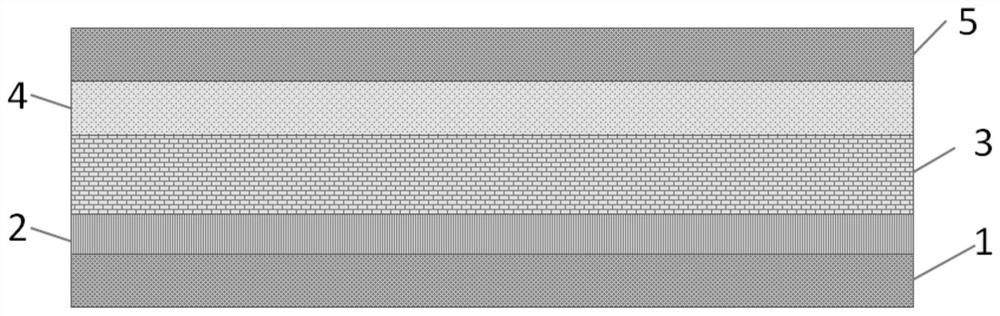

[0026] A composite foam glue, the thickness of which is the schematic diagram of its cross-sectional structure as figure 1 As shown, it includes a first acrylic glue layer 1, a TPU stretchable layer 2, a polyurethane foam layer 3, a PET layer 4 and a second acrylic glue layer 5 arranged in sequence;

[0027] Among them, the thickness of the first acrylic adhesive layer 1 is 0.1 mm, which is from Guangzhou Weisheng Electronics Co., Ltd.;

[0028] The thickness of the TPU stretchable layer 2 is 0.05mm, which comes from Guangzhou Weisheng Electronics Co., Ltd.;

[0029] The thickness of the polyurethane foam layer 3 is 1 mm, which is from Guangzhou Weisheng Electronics Co., Ltd.;

[0030] The thickness of the PET layer 4 is 0.05mm, which is from Guangzhou Weisheng Electronics Co., Ltd.;

[0031]The thickness of the second acrylic glue layer 5 is 0.1 mm, and it comes from Guangzhou Weisheng Electronics Co., Ltd.

Embodiment 2

[0033] A kind of composite foam glue, its structure is identical with embodiment 1, comprises the first acrylic glue layer (Guangzhou Weisheng Electronics Co., Ltd.) of 0.05mm in thickness that is arranged successively, the TPU stretchable layer (Guangzhou Weisheng Electronics Co., Ltd.) of 0.075mm in thickness (Guangzhou Weisheng Electronics Co., Ltd.), a polyurethane foam layer with a thickness of 0.25mm (Guangzhou Weisheng Electronics Co., Ltd.), a PET layer with a thickness of 0.075mm and a second acrylic glue layer with a thickness of 0.15mm (Guangzhou Weisheng Electronics Co., Ltd. ).

Embodiment 3

[0035] A kind of composite foam glue, its structure is identical with embodiment 1, comprises the first acrylic glue layer (Guangzhou Weisheng Electronics Co., Ltd.) of 0.15mm in thickness that is arranged successively, the TPU stretchable layer (Guangzhou Weisheng Electronics Co., Ltd.) of 0.025mm in thickness (Guangzhou Weisheng Electronics Co., Ltd.), a polyurethane foam layer with a thickness of 1.26mm (Guangzhou Weisheng Electronics Co., Ltd.), a PET layer with a thickness of 0.025mm and a second acrylic glue layer with a thickness of 0.05mm (Guangzhou Weisheng Electronics Co., Ltd. ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com