Preparation process of lactobacillus bulgaricus powder with high fermentation activity

A preparation process, Lactobacillus technology, applied in the direction of bacteria, preserved microorganisms, biochemical equipment and methods, etc., can solve the problem of low fermentation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

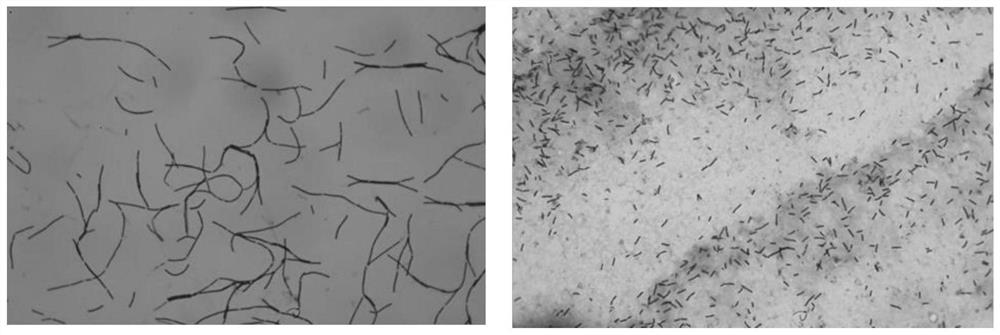

Image

Examples

Embodiment 1

[0037] (1) Strain activation: Under aseptic conditions, after the strains stored at -80°C were returned to room temperature, 2% inoculum was inoculated in 12% aseptic skim milk, and cultured at 37°C for 14 hours. The above conditions were continuously passaged for 3 times.

[0038] (2) Preparation of fermentation medium:

[0039] Accurately weigh 20g / L lactose, cottonseed peptone 8g / L, yeast extract powder 5g / L, fish peptone 3g / L, whey protein concentrate 1g / L, sodium acetate 5g / L, citric acid 0.25g / L, hydrogen phosphate Disodium 4g / L, magnesium sulfate 0.6g / L, manganese sulfate 0.3g / L, the above ingredients were added into purified water with 90% fermentation volume, adjusted to pH 6.6, and sterilized at 115°C for 20min to obtain culture medium A. Accurately weigh 4 g / L of 5'-taste nucleotide disodium and dissolve it in purified water with a fermentation volume of 5% to obtain medium B liquid.

[0040] Accurately weigh 0.55 g / L of sodium iso-D-ascorbate and dissolve it in 5% ...

Embodiment 2

[0053] (1) Strain activation: Under aseptic conditions, after the strains stored at -80°C were returned to room temperature, 2% inoculum was inoculated in 12% aseptic skim milk, and cultured at 37°C for 14 hours. The above conditions were continuously passaged for 3 times.

[0054] (2) Preparation of fermentation medium:

[0055] Accurately weigh 25g / L, cottonseed peptone 5g / L, yeast extract powder 8g / L, fish peptone 5.0g / L, whey protein concentrate 1.5g / L, sodium acetate 8g / L, citric acid 0.35g / L, phosphoric acid Disodium Hydrogen 5g / L, Magnesium Sulfate 0.5g / L, Manganese Sulfate 0.05g / L, the above ingredients were added to purified water with 95% fermentation volume, adjusted to pH 6.4, and sterilized at 115°C for 20min to obtain medium A liquid.

[0056] Accurately weigh 4 g / L of disodium 5'-inosinic acid nucleotide and 2 g / L of disodium 5'-guanylic acid nucleotide and dissolve them in purified water with 5% fermentation capacity to obtain culture medium B.

[0057] Accur...

Embodiment 3

[0070] (1) Strain activation: under aseptic conditions, after the strains stored at -80°C were returned to room temperature, 1% inoculum was inoculated in 15% aseptic skim milk, and cultured at 37°C for 14 hours. The above conditions were continuously passaged for 3 times.

[0071] (2) Preparation of fermentation medium:

[0072] Accurately weigh 15g / L, cottonseed peptone 6g / L, yeast extract powder 5g / L, fish peptone 3g / L, whey protein concentrate 0.5g / L, sodium acetate 2g / L, citric acid 0.2g / L, hydrogen phosphate Disodium 3g / L, magnesium sulfate 0.2g / L, manganese sulfate 0.05g / L, the above ingredients were added to purified water with 95% fermentation volume, adjusted to pH 6.4, and sterilized at 115°C for 20min to obtain culture medium A.

[0073] Accurately weigh 4 g / L of disodium 5'-inosinic acid nucleotide and 2 g / L of disodium nucleotide nucleotide and dissolve them in purified water with 5% fermentation volume to obtain culture medium B.

[0074] Accurately weigh 0.80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com