Method and system for measuring surface tension of liquid metal in welding pool in real time

A technology of liquid metal and surface tension, applied in surface tension analysis, measuring devices, surface/boundary effects, etc., can solve problems such as difficult real-time measurement of surface tension, and achieve high sampling rate, good application prospects, and high signal-to-noise ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

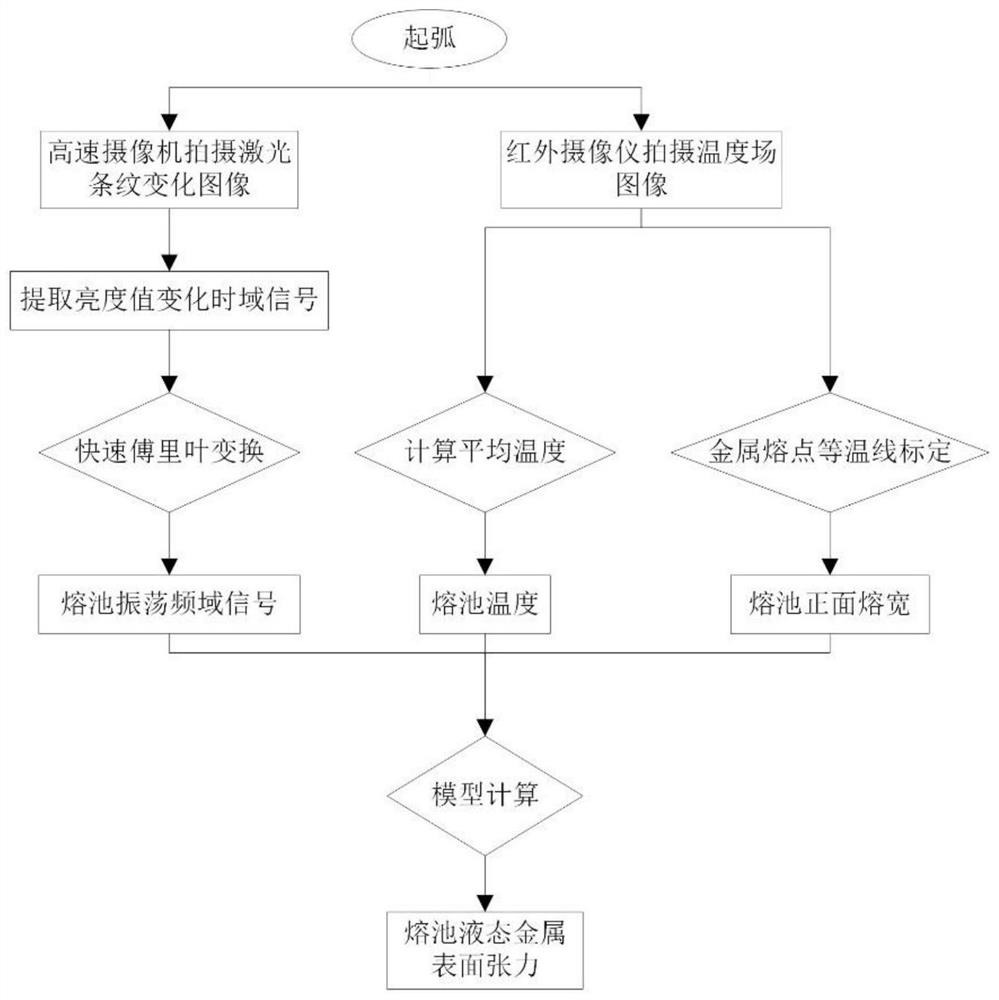

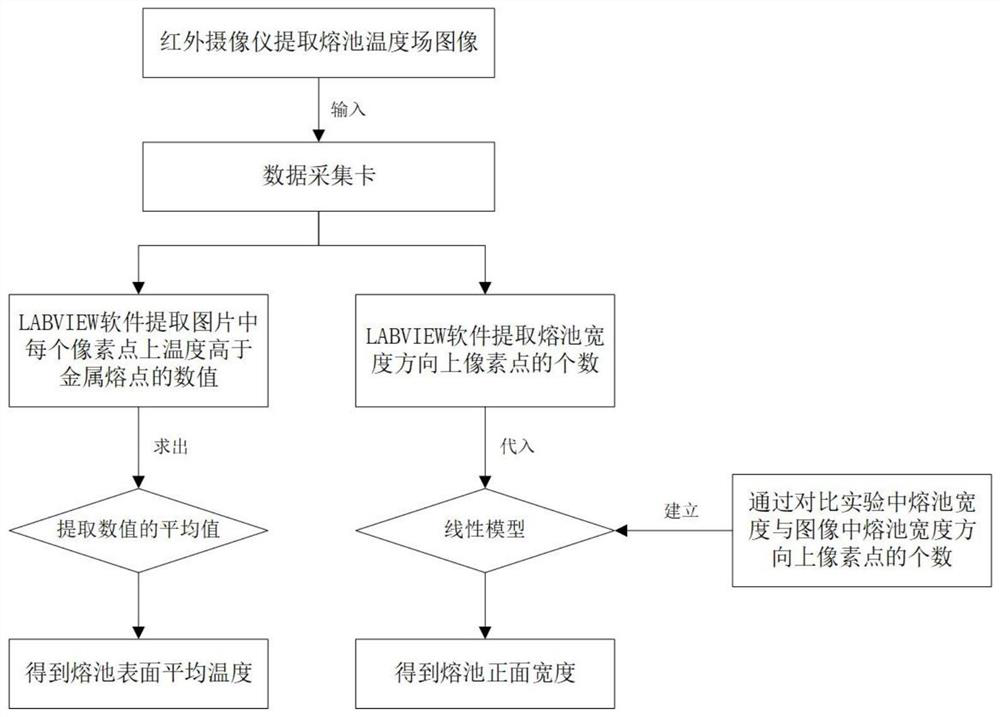

[0052] The embodiment of the invention discloses a method for real-time measurement of the surface tension of the liquid metal in the welding pool, such as figure 1 As shown, the method includes the following steps:

[0053] S1. Real-time projection of the laser stripes reflected by the emitted beam of the laser on the surface of the molten pool that produces the oscillation phenomenon of the molten pool; obtaining the change of the laser stripes; measuring the temperature field image of the molten pool at the moment of arc extinction;

[0054] In step S1, the emitted light beam is adjustable five-line fringe and single-line fringe. The laser stripes are reflected behind the surface of the pool, and the laser stripes can be displayed in real time through projection processing, and the changes of the laser stripes can be obtained by obtaining the projected images displayed in real time. In the actual application process, the laser stripes are projected on the imaging screen, a...

Embodiment 2

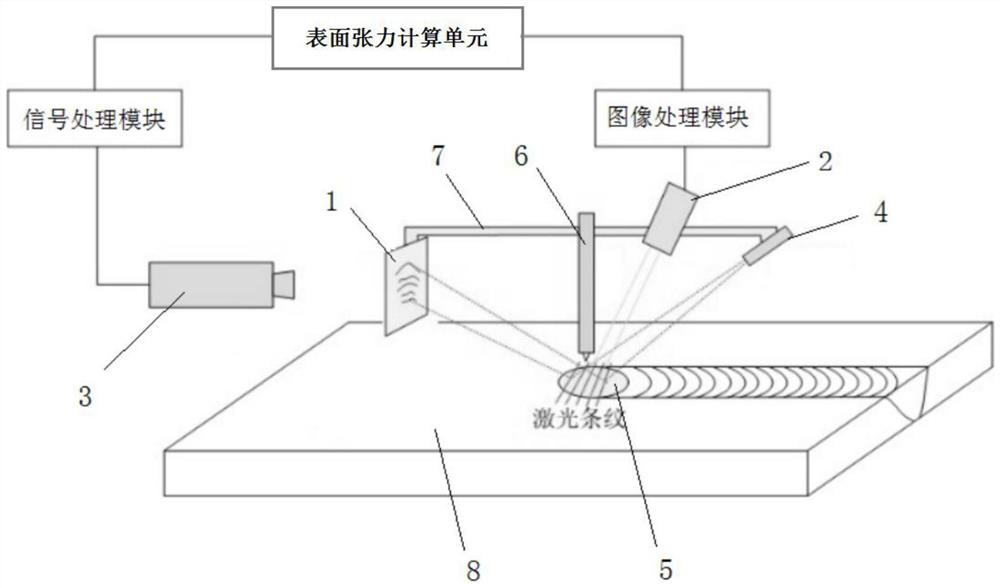

[0080] A system for real-time measurement of the surface tension of the liquid metal in the weld pool, such as image 3 As shown, the system includes a parameter acquisition unit, a parameter processing unit and a surface tension calculation unit; wherein,

[0081] The parameter acquisition unit includes an imaging screen 1, an infrared thermometer 2, a high-speed camera 3 and a laser 4; wherein,

[0082] The laser 4 is used to emit a five-line or single-line structured beam;

[0083] The imaging screen 1 is used to project in real time the laser stripes reflected by the emitted light beam of the laser 4 irradiating the surface of the molten pool 5 that produces the molten pool oscillation phenomenon;

[0084] The high-speed camera 3 is used to obtain the changes of the laser stripes on the imaging screen 1;

[0085] The infrared thermometer 2 is used to measure the temperature field image of the melting pool at the moment of arc extinction;

[0086] The parameter processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com