Subsurface imaging device

An imaging device and sub-surface technology, applied in the field of imaging, can solve the problems of low efficiency, difficult imaging, slow speed, etc., and achieve the effects of improving light intensity, improving imaging speed and efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It can be seen from the background art that the devices in the prior art that realize subsurface imaging based on the principle of total internal reflection have the problems of slow imaging speed and low imaging efficiency. Now combine an imaging device based on the principle of total internal reflection to analyze the reasons for its slow imaging speed and low imaging efficiency:

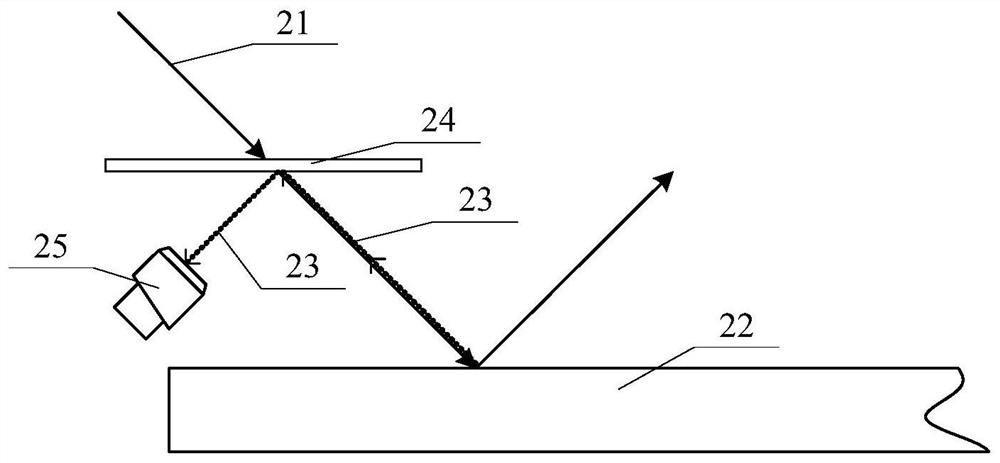

[0041] refer to figure 1 , shows a schematic diagram of the optical path structure of a subsurface imaging device.

[0042] The illumination light 21 produced by the light source (not shown in the figure) is incident on the surface of the object to be imaged 22; ray 23 for imaging.

[0043] In order to improve the local illumination light intensity, the imaging device generally adopts a line light source to generate illumination light 21, so the formed illumination light 21 is a one-dimensional light in the direction perpendicular to the paper surface; , the incident position of the illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com