Hydrogen sensor and application thereof

A sensor, hydrogen technology, applied in the field of hydrogen sensors, to achieve good application prospects, good anti-vibration performance, fast response and recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

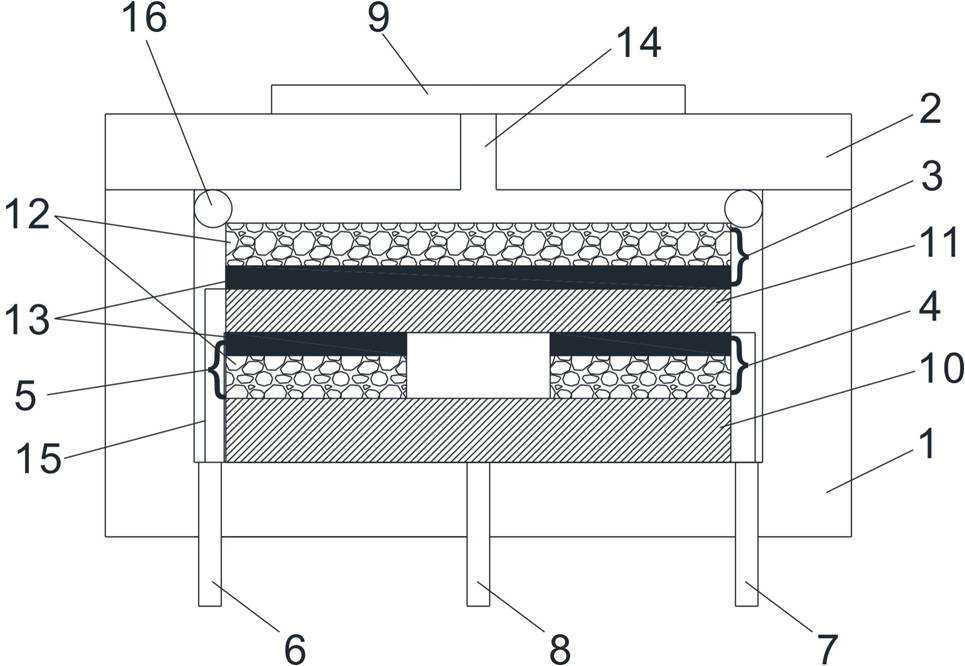

[0025] Such as figure 1As shown, a hydrogen sensor, the sensor is a three-electrode system, the sensor includes a housing 1, an upper cover 2, a working electrode 3, a counter electrode 4, a reference electrode 5, a working electrode pin 6, a counter electrode lead Pin 7, reference electrode pin 8, dust-proof and breathable film 9, anti-vibration layer 10, liquid-absorbing material layer 11, the working electrode 3, counter electrode 4, and reference electrode 5 are all made of PTFE film 12 (polytetrafluoroethylene) Vinyl film) and platinum black 13 coated on one side; the upper cover 2 and the shell 1 are fastened to form an internal cavity structure; the top of the upper cover 2 is provided with a diffusion hole 14, and the dust-proof and breathable membrane 9 is arranged on the upper cover 2 The top covers the diffusion hole 14; the working electrode pins 6, the counter electrode pins 7 and the reference electrode pins 8 are arranged at the bottom of the shell 1 at interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com