Production process of high-binding-force elisa plate

A production process and microplate technology, which is applied in the field of biological instruments, can solve the problems of increasing the amount of protein and weak binding ability between microplate and protein, and achieve the effect of smooth plate surface and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

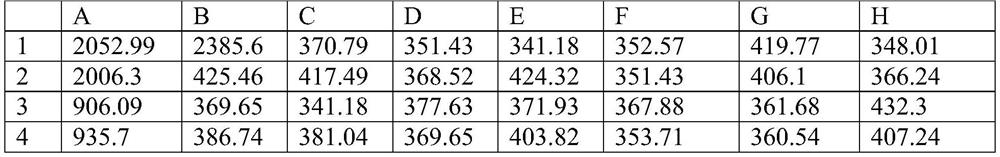

Examples

Embodiment 1

[0064] The present embodiment provides a kind of production technique of high-binding force microtiter plate, comprises the following steps:

[0065] S1: The polystyrene beads and steam are continuously mixed in a pre-foaming machine under the stirring of the stirring tank to complete the foaming reaction. The pre-expanding machine is kept open at atmospheric pressure, and the polystyrene beads that have been expanded are overflowed from the top of the pre-expanding machine. After the polystyrene beads are foamed, aging treatment is carried out so that air is mixed into the cells to obtain aged pre-expanded beads. Put the cured pre-expanded beads into the molding equipment for molding treatment to obtain a 12×8 96-well microplate.

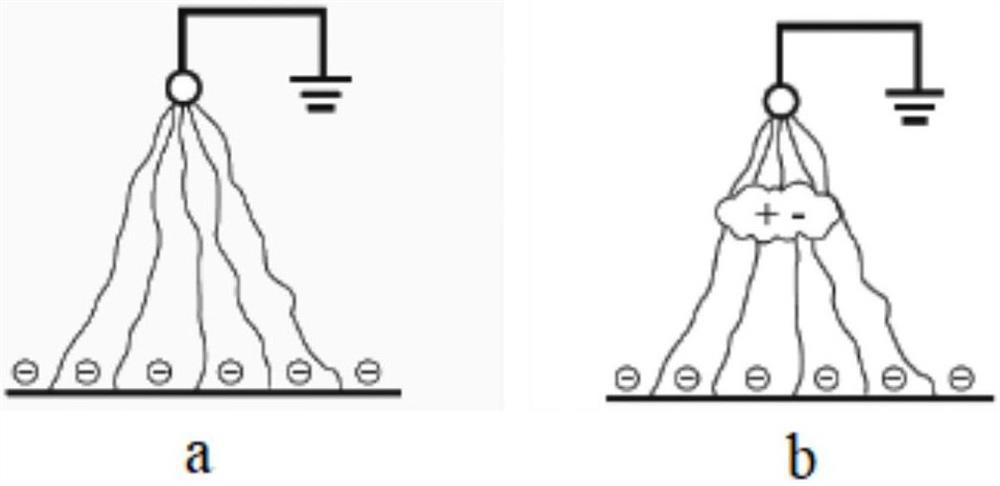

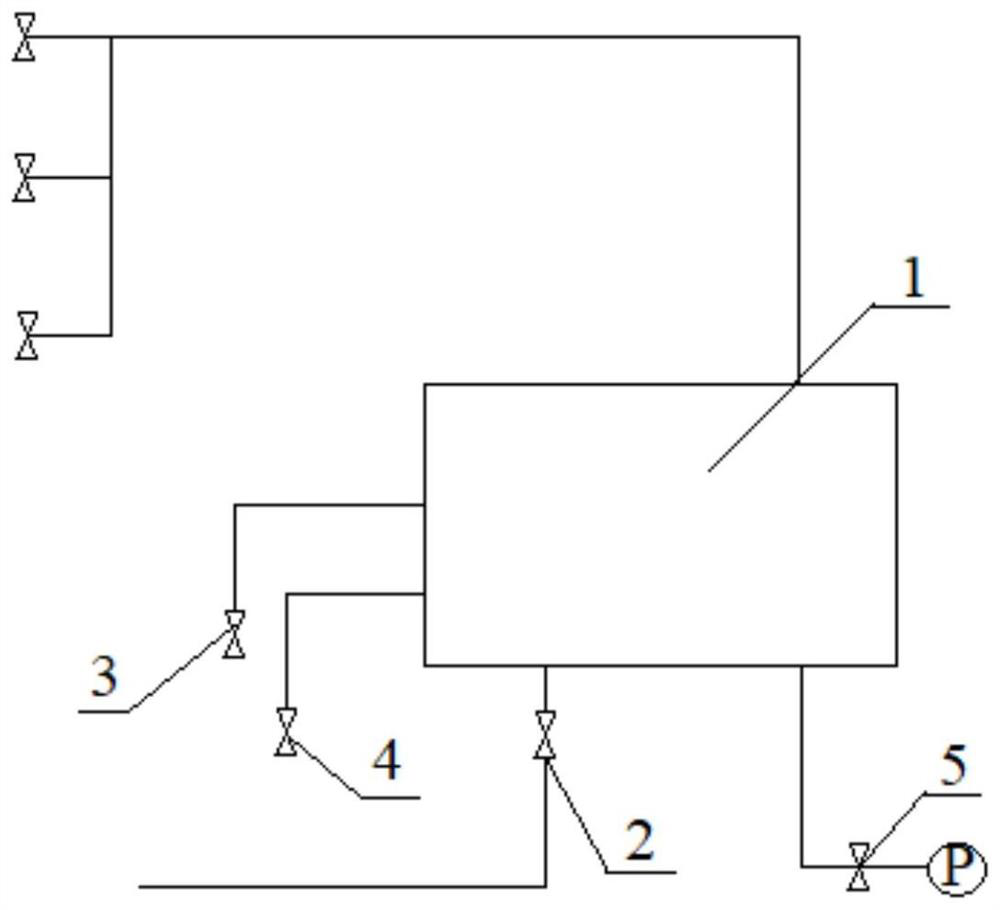

[0066] S2: Place the microplate prepared in step S1 in the plasma surface treatment equipment, open the reaction gas inlet valve 2 and the exhaust valve 5, and pass compressed air into the plasma surface treatment equipment, and the compressed air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Average concentration | aaaaa | aaaaa |

| Average concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com