Conical rod laser amplifier

A laser amplifier and seed technology, applied in lasers, laser parts, laser parts, etc., can solve the problems of low repetition frequency output, unable to provide sufficient gain, unable to fully use the round rod gain medium, etc., to reduce components, reduce Optical power density, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

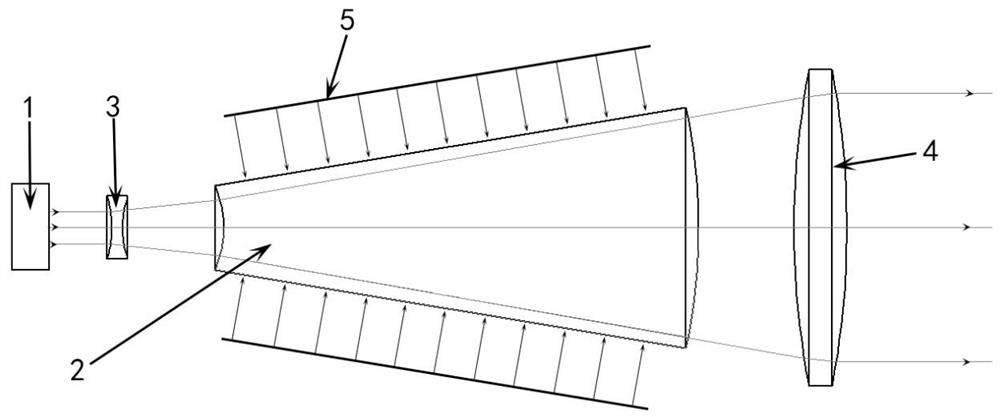

[0032] This embodiment provides a cone-rod laser amplifier, including a pumping source 5, a seed source 1, a diverging lens 3, a cone-rod gain medium 2 and a collimating lens 4 coaxially arranged in sequence, the seed source 1 and the pumping source 5 emit seed light and pump light respectively, the structure is as follows figure 1 shown.

[0033] The diverging lens 3 will be 3mm*3mm (or 3mm) parallel incident seed light diverges with a divergence angle of 5°.

[0034] The cone-rod gain medium 2 uses Nd:YAG crystal, Nd 3+ The doping concentration is 0.8%, and the length is 85 mm; the incident end surface of the cone-rod gain medium 2 is the spherical cap of the spherical cone A, the spherical radius of the spherical cone A is 45 mm, the center of the sphere coincides with the focal point of the diverging lens, and the incident end surface The radius of the bottom is 4 mm, and the height is 0.18 mm; the exit end surface is the spherical cap of the spherical cone B, the sph...

Embodiment 2

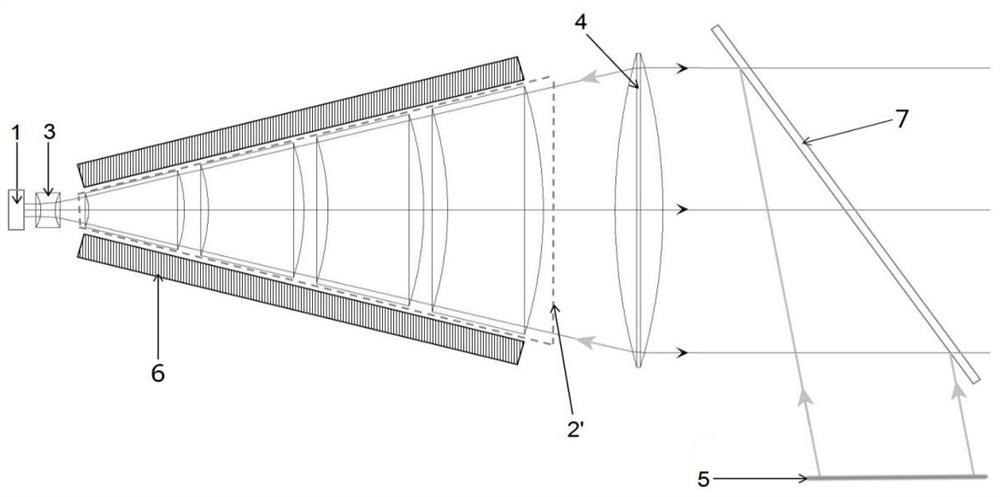

[0041] This embodiment provides a multi-stage cone-rod laser amplifier, including a pump source 5, a heat sink 6, a dichroic mirror 7, and a seed source 1, a diverging lens 3, and a cone-rod gain medium group 2' coaxially arranged in sequence. And collimating lens 4, seed source 1 and pump source 5 emit seed light and pump light respectively, the structure is as follows figure 2 shown.

[0042] The diverging lens 3 will 3 mm parallel incident seed light diverges with a spread angle of 5°.

[0043] The cone-rod gain medium group 2' is composed of a multi-stage cone-rod gain medium, the overall profile is in the shape of a spherical cone, and Nd:YAG crystal is used, wherein Nd 3+ The doping concentration is 0.8%; the incident end face and the exit end face of the cone-rod gain medium at all levels are spherical cone spherical caps, and the centers of the spheres coincide with the focus of the diverging lens 3, and the center angles are equal. The length of the medium is 20...

Embodiment 3

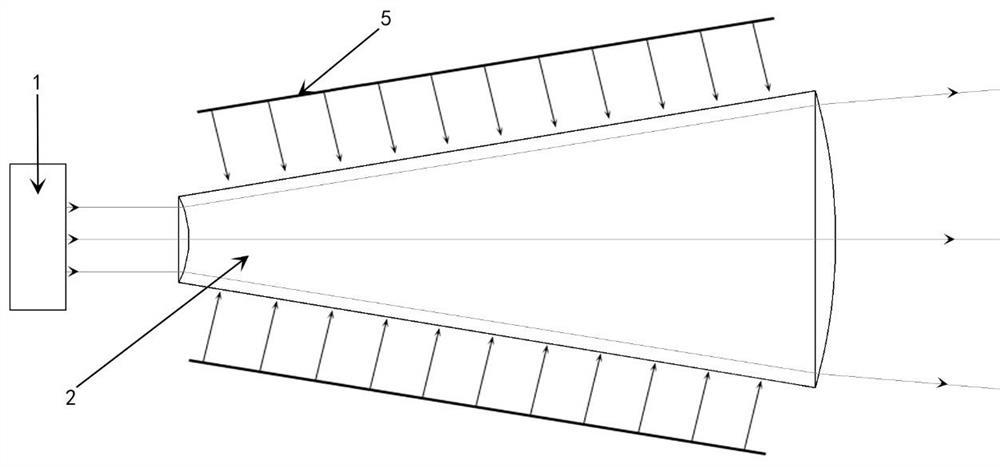

[0050] This embodiment provides an improved cone-rod laser amplifier, including a pumping source 5, a seed source 1 and a cone-rod gain medium 2 coaxially arranged, and the seed source 1 and the pumping source 5 send out seed light and pumping light respectively. light, structured as image 3 shown.

[0051] The cone-rod gain medium 2 is Nd:YAG crystal, Nd 3+ The doping concentration is 0.8%, and the refractive index n=1.82; the cone-rod gain medium 2 is an axirotationally symmetrical figure, its incident end surface is the spherical cap of spherical cone A, its outgoing end surface is the spherical cap of spherical cone B, and its side is a frustum of a cone side; wherein, the spherical cone A and the spherical cone B are coaxial, and are located on the rotational symmetry axis of the incident or outgoing end surface close to the seed source; the spherical radius of the spherical cone A is 15.53 mm, and the bottom of the incident end surface is The diameter is 4mm, larger t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com