A Curved Slab Laser Amplifier

A technology of laser amplifiers and curved panels, which is applied to lasers, laser components, phonon exciters, etc., can solve the problem of not being able to fully utilize the slab medium for energy storage, and achieve a simple structure, small volume, and stable optical power density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

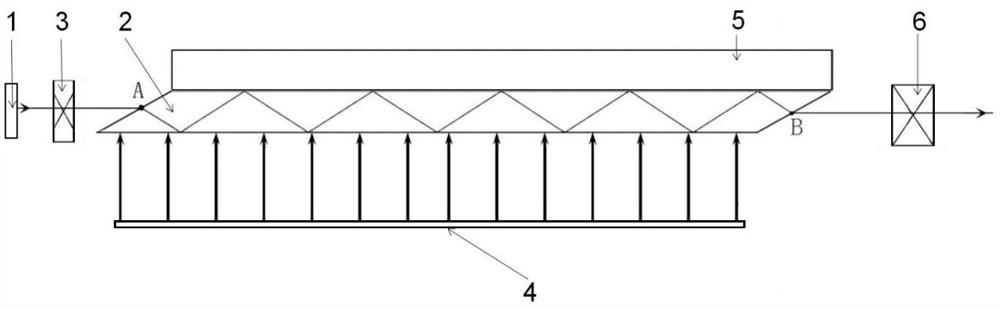

[0030] This embodiment provides a curved slab laser amplifier, including a pump source 4, a heat sink 5, and a seed source 1, a diverging cylindrical lens 3, a curved slab medium 2 and a collimating cylindrical lens 6 coaxially arranged in sequence, Its structure is as figure 1 and image 3 As shown, the pumping light emitted by the pumping source 4 is incident on the lower surface of the curved strip medium 2 to pump the curved strip medium 2, and the heat sink 5 is located on the upper surface of the curved strip medium 2, and the curved surface Panel strips medium 2 for cooling.

[0031] The spot of the seed light emitted by the seed source 1 is a square spot of 1.5mm*1.5mm, which is parallel incident to the diverging cylindrical lens 3 .

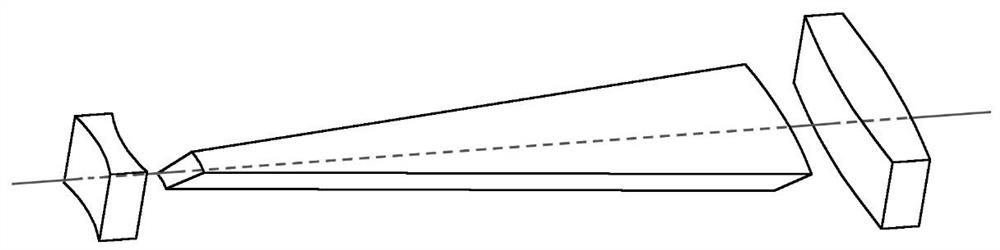

[0032] The diverging cylindrical lens 3 diverges the seed light, and the diffusion angle of the seed light =15°, one of the divergent paths can be seen as figure 1 shown by the dotted line.

[0033] The curved strip medium 2 adopts...

Embodiment 2

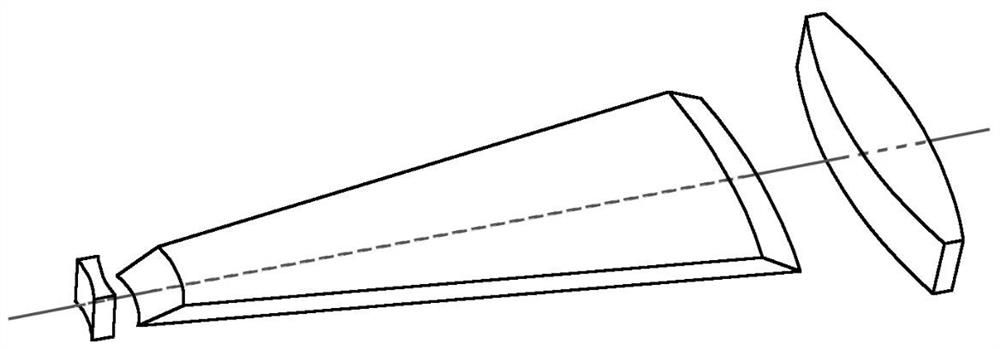

[0042] This embodiment provides a curved slab laser amplifier, including a pump source 4, a heat sink 5, and a seed source 1, a diverging cylindrical lens 3, a curved slab medium 2 and a collimating cylindrical lens 6 coaxially arranged in sequence, Its structure is as Figure 4 and Figure 6 As shown, the pump light emitted by the pump source 4 is incident on the lower surface of the curved strip medium 2 near the sharp corner, pumping the curved strip medium 2, and the heat sink 5 is located on the curved strip medium 2 The non-pumped areas of the large surface and the lower large surface cool the curved strip medium 2 .

[0043] The spot of the seed light emitted by the seed source 1 is a square spot of 1.5mm*1.5mm, which is parallel incident to the diverging cylindrical lens 3 .

[0044] The diverging cylindrical lens 3 diverges the seed light, and the diffusion angle of the seed light =15°, one of the divergent paths can be seen as Figure 4 shown by the dotted line....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com