Five-phase induction motor winding design with star pentagon winding connection mode

A winding connection and induction motor technology, which is applied in the shape/style/structure of the winding conductor to reduce the core loss and vibration noise, improve the winding factor, and be easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

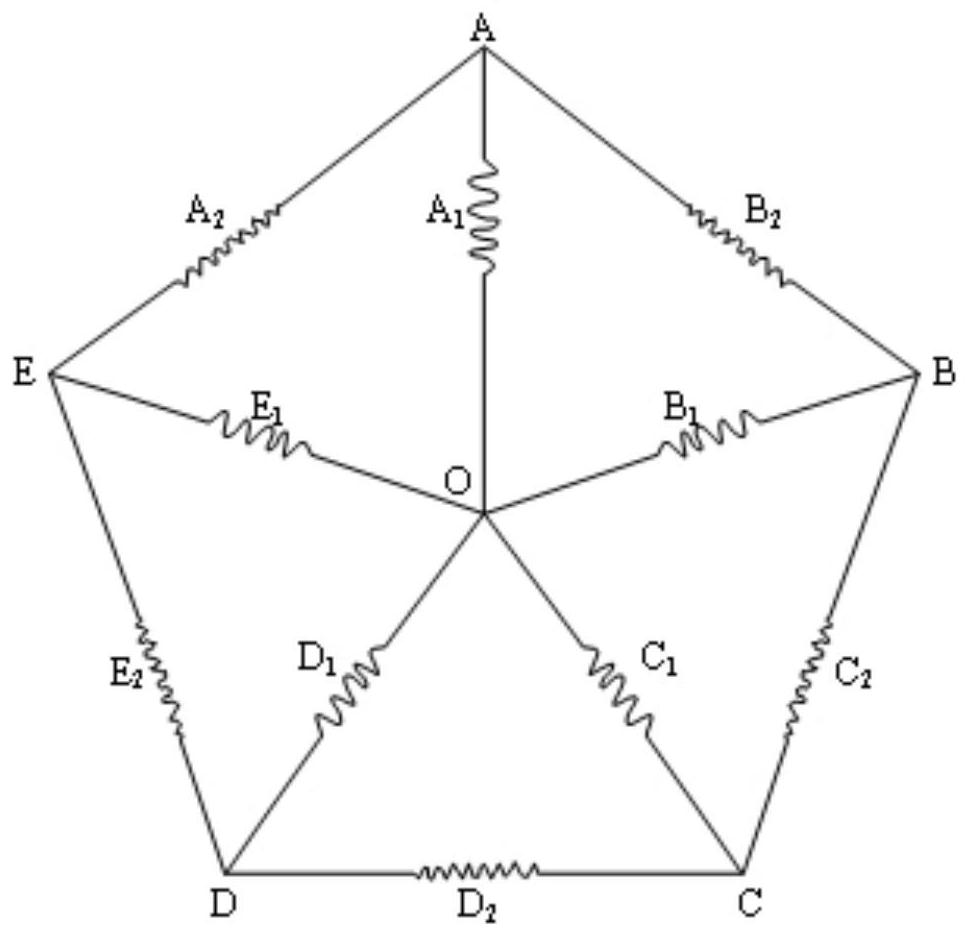

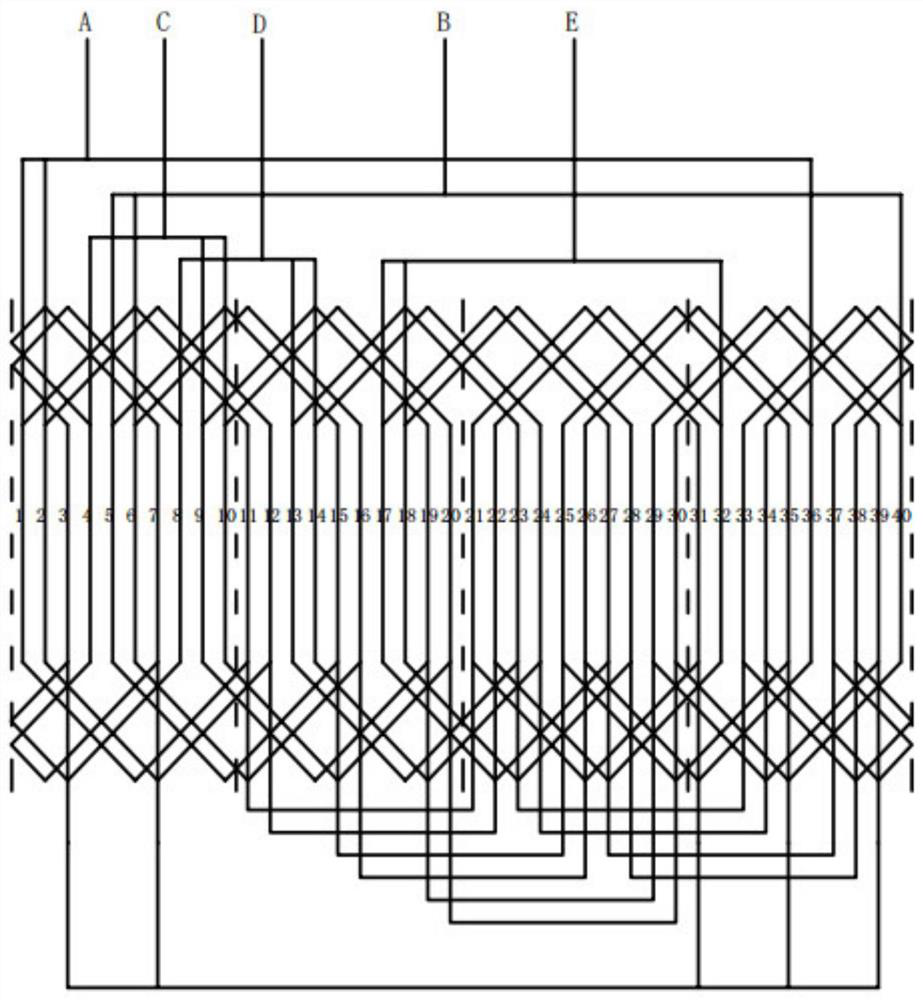

[0024] Specific implementation mode one: combine figure 1 The schematic diagram of the motor winding shown is for illustration. The five-phase induction motor is a single-layer winding with 40 slots; the star pentagonal winding is designed as an external pentagonal internal star winding. Two parts of the winding, and then connect the five lead-out wires of the star-shaped partial winding to the five corresponding vertices of the pentagonal partial winding, and then connect the five lead-out wires of the pentagonal partial winding to the five-phase power supply.

specific Embodiment approach 2

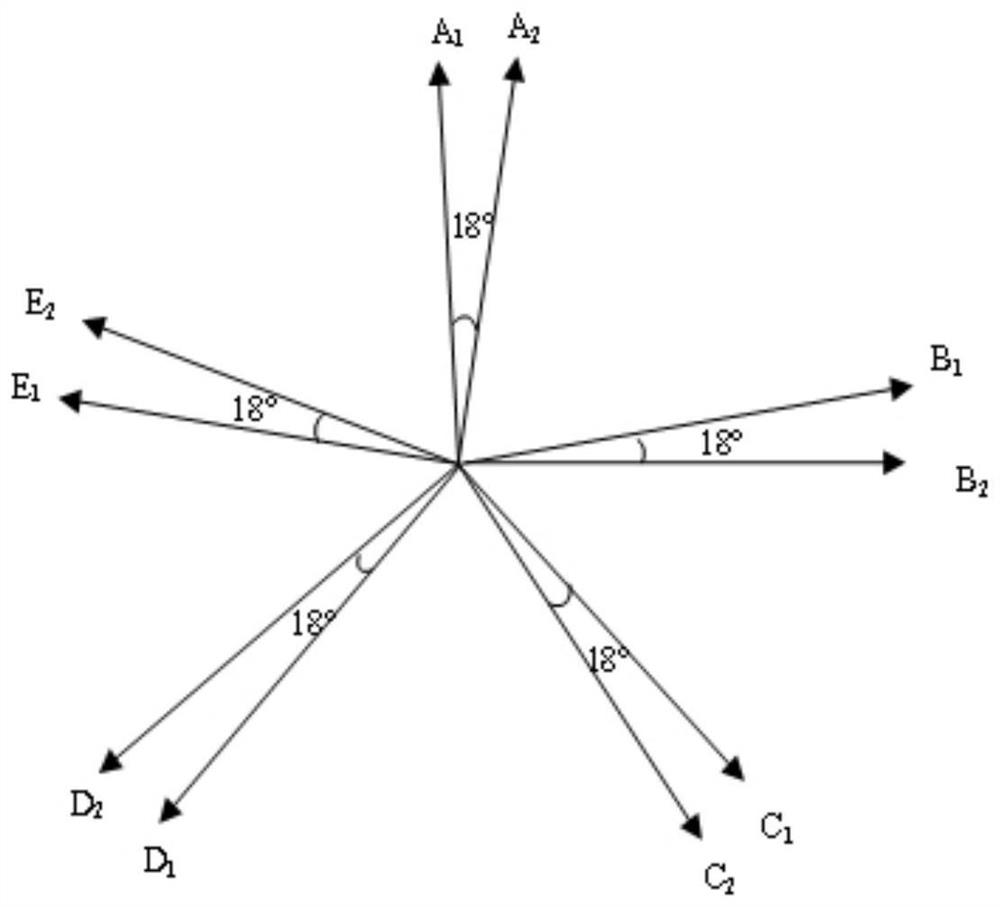

[0025] Specific implementation mode two: combination figure 2 The electrical angle distribution diagram of the motor is shown for illustration. The pitch of this star pentagonal winding coil is 10, and the whole pitch; by dividing each phase belt of the ordinary star winding into two parts: pentagonal and star-shaped , that is, the number of slots occupied by each phase winding under each pole is divided into two equal parts, and the pentagonal and star-shaped windings are arranged alternately. , and there is an electrical angle difference of 18° between the pentagon and the star.

specific Embodiment approach 3

[0026] Specific implementation method three: the star part of the winding is composed of five branches A1, B1, C1, D1, and E1, and the five branches are separated by an electrical angle of 72°; the first and last ends of A1 are respectively marked as a1 and a2; The first and last ends of C1 are respectively marked as c1 and c2; the first and last ends of D1 are respectively marked as d1 and d2; the first and last ends of E1 are respectively marked as e1 and e2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com