Flue gas desulfurization and denitrification system and use method thereof

A technology for desulfurization and denitrification and flue gas, which is applied in the field of flue gas desulfurization and denitrification systems, can solve the problems of inability to clean up the attachments on the inner wall of the tank, low efficiency of flue gas desulfurization and denitrification, etc., to improve the protection ability and reaction efficiency, and improve the spraying effect , Improve the effect of reaction contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

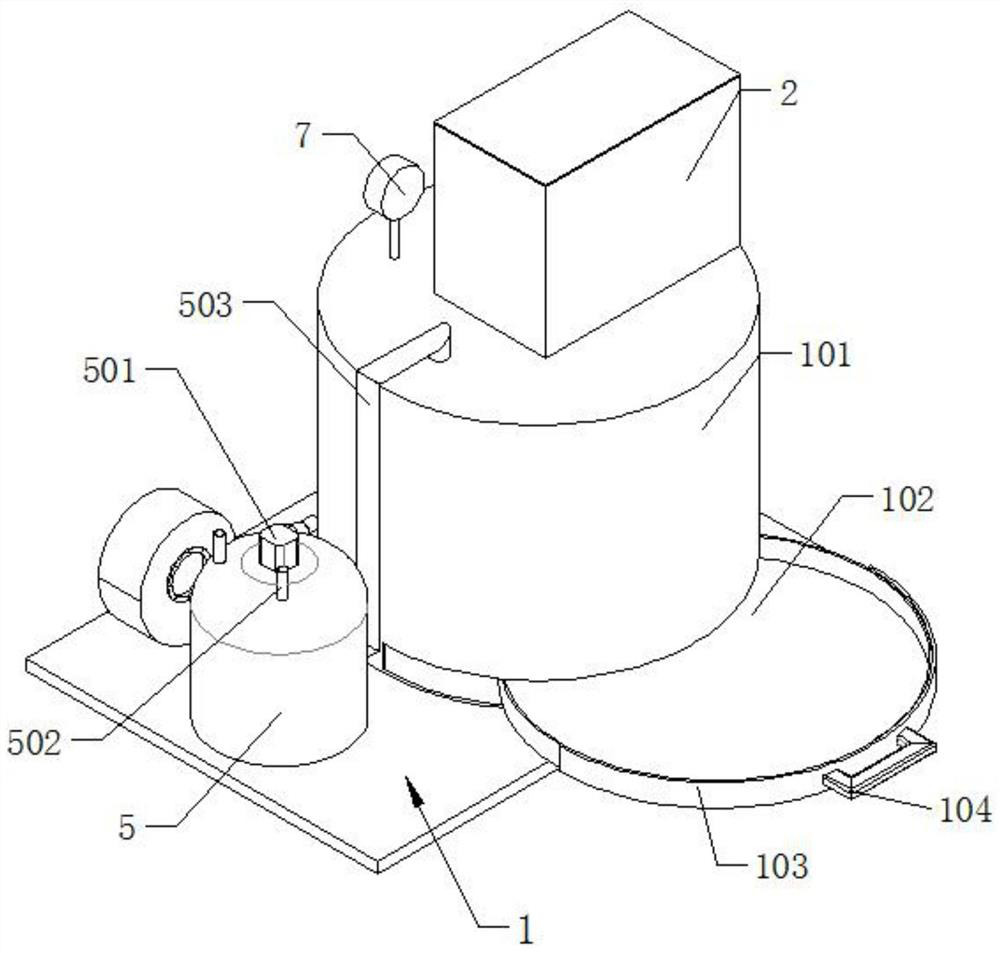

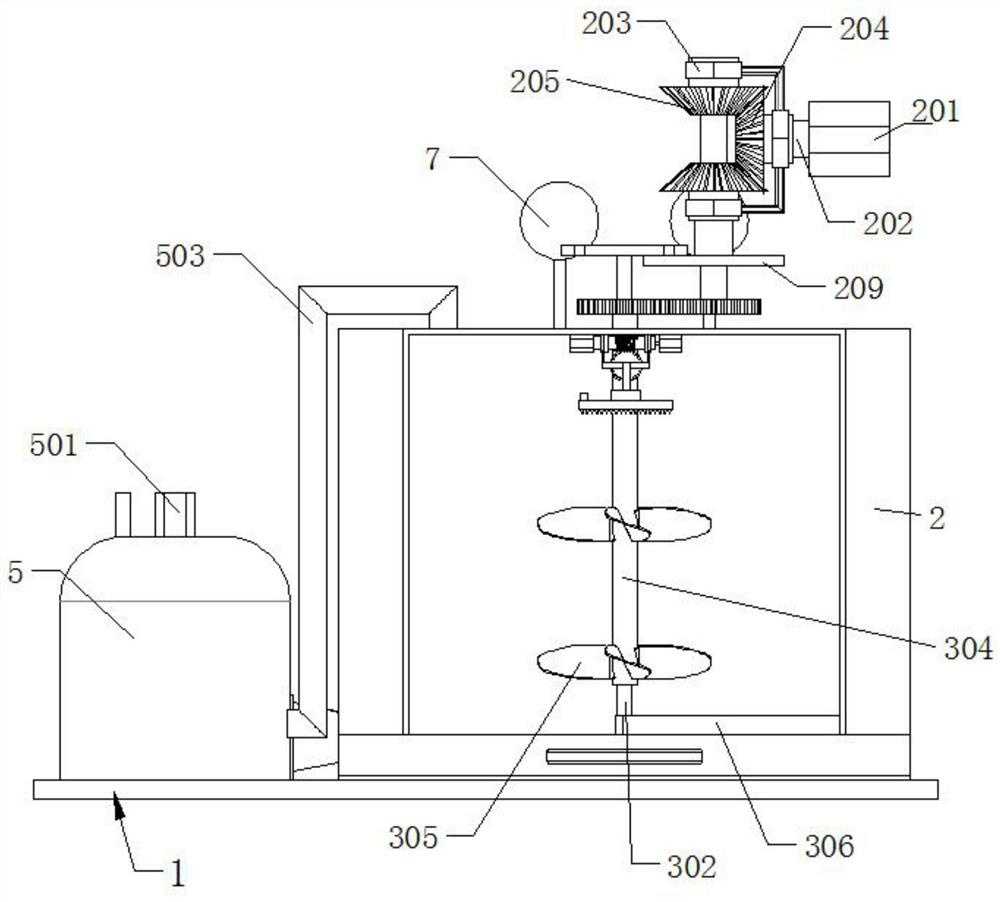

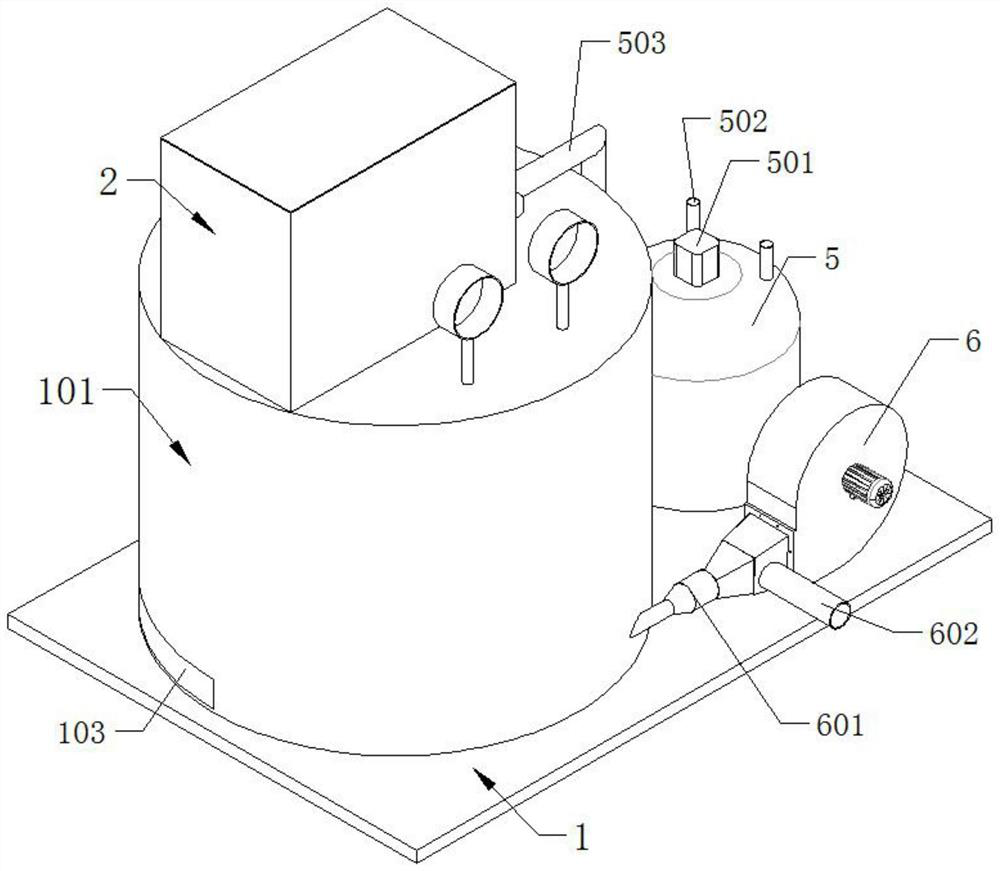

[0038] refer to Figure 1-8 , a flue gas desulfurization and denitrification system and a method of use thereof, comprising a base plate 1, a reaction tank 101 connected to the top of the base plate 1, a smoke delivery mechanism and a delivery mechanism connected to the top of the base plate 1, the smoke delivery mechanism and the delivery mechanism cooperate with the reaction tank 101 , the top of the reaction tank 101 is fixedly connected with a transmission box 2, and the inner cavity of the transmission box 2 is connected with a driving mechanism. Stirring mechanism, the stirring mechanism includes a second outer shaft 304, the second outer shaft 304 is rotatably connected to the top of the reaction tank 101, the inner wall of the second outer shaft 304 is rotatably connected with a wall-cleaning mechanism, and the wall-cleaning mechanism includes a second inner shaft 302, the second The inner shaft 302 is rotatably connected to the inner cavity of the second outer shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com