Battery slurry anti-splashing uniform coating device

A coating device and anti-splash technology, which can be applied to devices for coating liquid on the surface, battery electrodes, mixers with rotary stirring devices, etc. , The slurry is sprayed to other positions above the machine head or the operator, etc., to achieve the effect of saving production raw materials, stable production, and stable discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

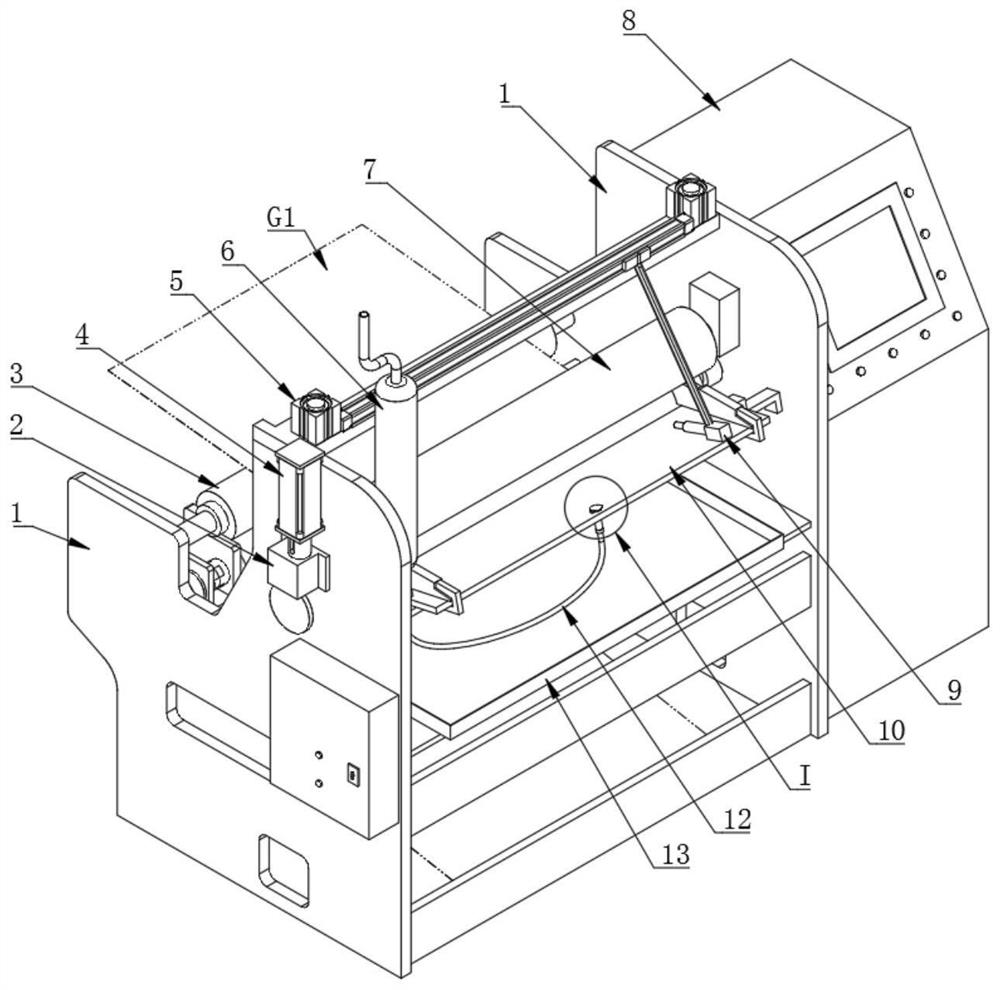

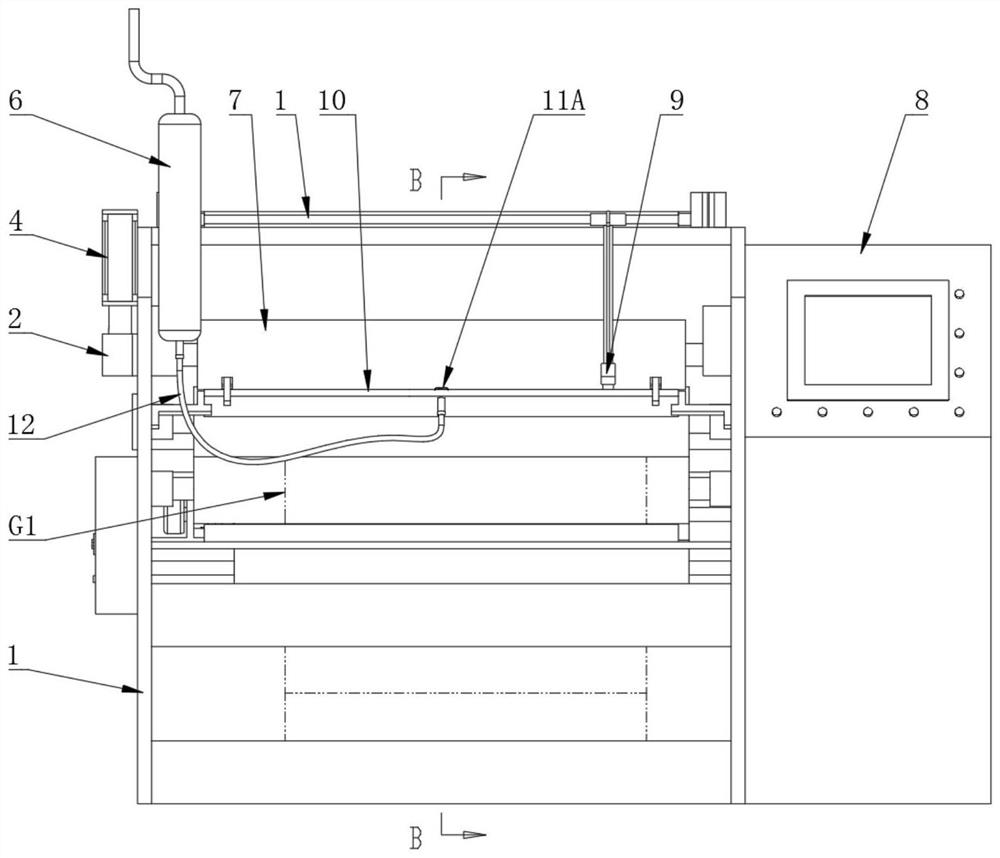

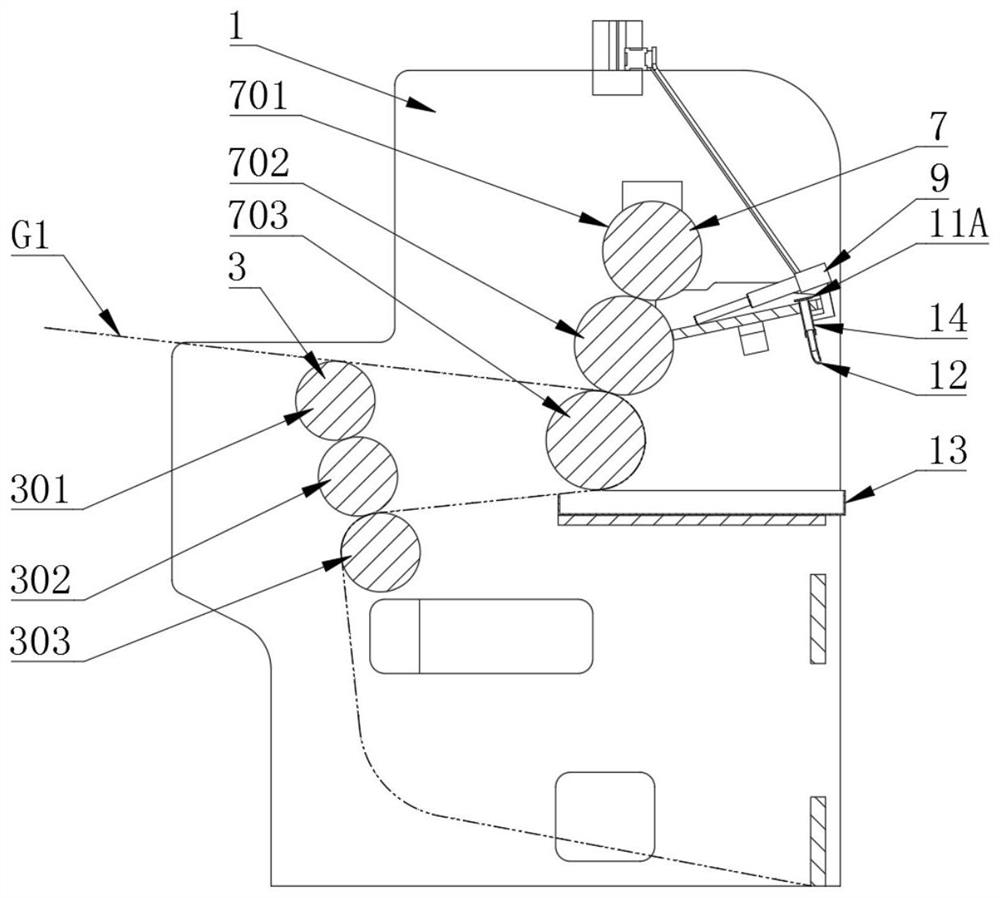

[0037] Such as figure 1 , 2 As shown, a battery slurry anti-splash uniform coating device disclosed in the present invention includes a bracket 1, a reducer 2 arranged on the bracket 1, a first three-roller mechanism 3, and a second three-roller mechanism 7. Inlet motor 4, cylinder 5, slurry filter 6, power control system 8, slurry coating tank 10, slurry coating tank 10 above one side of the slurry coating tank 13. A liquid outlet pipe hole 1001 is provided at the corresponding position on the slurry liquid coating collection tank 13 of the slurry liquid coating tank 10, and a liquid outlet pipe 14 is set inside the liquid outlet pipe hole 1001, and the slurry liquid connecting pipe 12 One end of the slurry connection pipe 12 is connected to the slurry filter 6, and the other end is connected to the outlet pipe hole 1001 in the slurry coating collection tank 13 on the slurry coating tank 10; On the slurry coating tank 10, set up an anti-slurry liquid splash mechanism and a ...

Embodiment 2

[0043] Such as Figure 4 , 5 , 7, a battery slurry liquid anti-splash uniform coating device disclosed in the present invention, the anti-splash device adopts another kind of movable anti-splash device; The silicone elastic part 1102A or the spring elastic part 1102A', the silicone elastic part 1102A or the spring elastic part 1102A' is set on the bottom plate surface of the slurry coating collection tank 13 located in the slurry coating tank 10 of the liquid outlet pipe 14 Above, the cover plate 1101A is arranged above the outlet end of the liquid outlet pipe 14, and the silicone elastic member 1102A or the spring elastic member 1102A′ is linked with the cover plate 1101A correspondingly. Under the action of the working internal pressure, the cover plate 1101A is washed away, and the slurry is output from the liquid outlet pipe 14 and flows into the slurry coating collection tank 13 of the slurry coating tank 10 , and control the working internal pressure in the slurry pump...

Embodiment 3

[0045] Such as Figure 8-10 As shown, the invention discloses a battery slurry anti-splash uniform coating device, and the anti-splash device adopts a fixed anti-splash device; the fixed anti-splash device includes a rectangular parallelepiped structure and In the middle of the structure, there are step-shaped card slots 1105B, liquid baffle slots 11B, upper side wall panels 1101B, lower side wall panels 1102B, circular card slots 1103B, fastening screws 1104B; circular card slots 1103B, fastening screws 1104B are set On the corresponding position of the lower side wall plate 1102B; the slot-shaped structure of the circular slot 1103B matches the shape and structure of the feed-liquid connecting pipe 12; the step-shaped slot 1105B is fixed on the slurry by fastening screws 1104B On the slurry coating tank 10 at the connection material liquid connecting pipe 12 of the liquid coating tank 10; that is, the shape is a cuboid structure liquid baffle tank 11B and the fixed splash gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com