Biochar-based passivator for acid soil remediation and preparation method thereof

A technology of biochar and passivating agent, which is applied in the field of agriculture, can solve the problems of heavy metal mercury secondary pollution, etc., and achieve the effect of promoting crop growth, simple operation, simple and feasible application steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

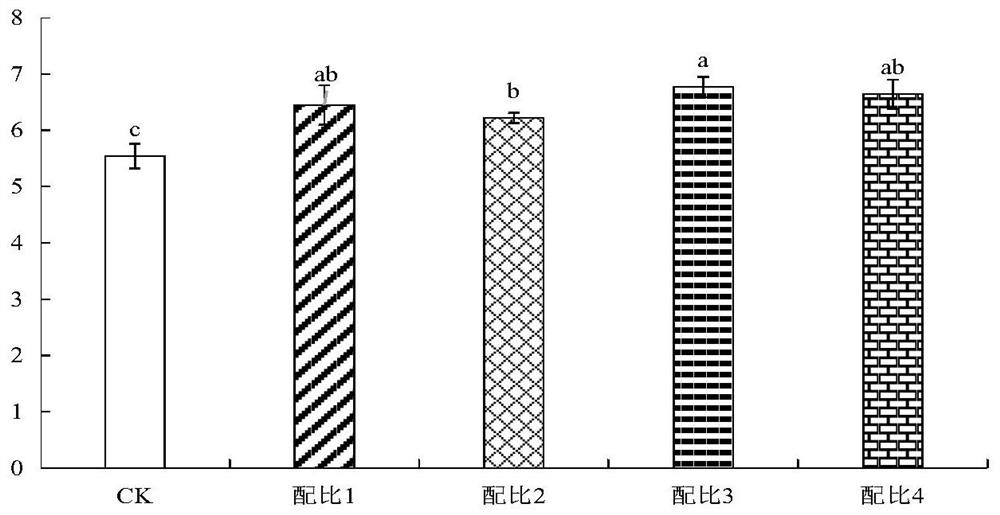

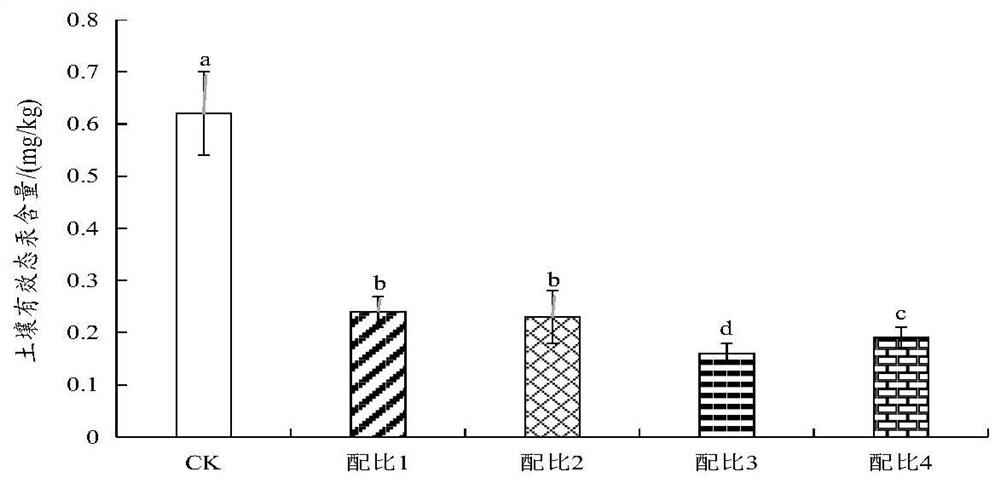

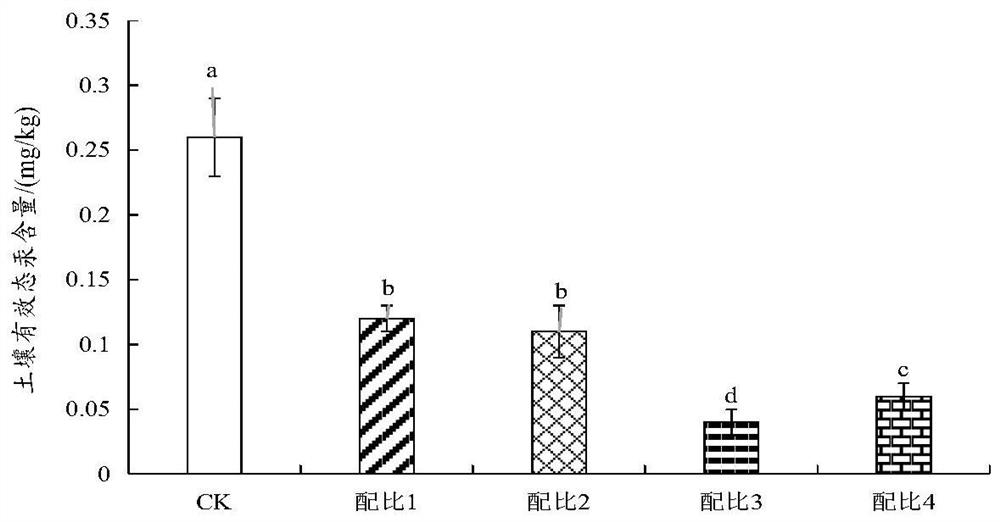

Examples

Embodiment 1

[0042] The preparation method of biochar-based passivator is as follows:

[0043]1) Combination of raw materials: 40kg of cow dung biochar, 10kg of polyacrylamide, 10kg of weathered coal, 20kg of quicklime, 10kg of bentonite, 10kg of camellia shell-hydrothermal carbon material and 10kg of magnesium silicate-hydrothermal carbon material;

[0044] 2) Biochar, weathered coal, quicklime, bentonite, camellia oleifera shell-hydrothermal carbon material and magnesium silicate-hydrothermal carbon material are mixed and granulated, polyacrylamide is melted in water, wrapped and freeze-dried for 2-3 hours.

Embodiment 2

[0046] The preparation method of the biochar-based passivator is consistent with Example 1, except that the dosage of each component is: 30kg of cow dung biochar, 20kg of polyacrylamide, 20kg of weathered coal, 10kg of quicklime, 20kg of bentonite, camellia oleifera shell-hydrothermal carbon material 5kg and magnesium silicate-hydrothermal carbon material 5kg.

Embodiment 3

[0048] The preparation method of the biochar-based passivator is consistent with Example 1, except that the dosage of each component is: 38kg of cow dung biochar, 12kg of polyacrylamide, 18kg of weathered coal, 12kg of quicklime, 18kg of bentonite, camellia oleifera shell-hydrothermal carbon material 6kg and magnesium silicate-hydrothermal carbon material 6kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com