Method for preparing nickel-titanium shape memory alloy with gradient nano-grain structure

A nano-grain and memory alloy technology, which is applied in metal rolling, manufacturing tools, heat treatment equipment, etc., can solve problems such as limited strength and fatigue life, degradation of material mechanical properties, and reduced component stability, so as to reduce energy consumption Dispersion, low cost, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

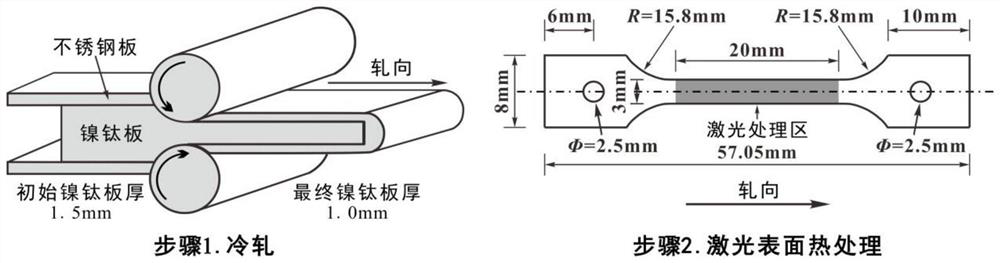

[0020] Below by example, in conjunction with the accompanying drawings, the technical solution of the present invention is further specifically described, as figure 1 As shown, a method for preparing a gradient nanograin structure nickel-titanium shape memory alloy, a commercial coarse-grained superelastic nickel-titanium alloy plate with an initial thickness of 1.5 mm and a chemical composition of 50.8% atomic nickel and 49.2% titanium is as follows For processing:

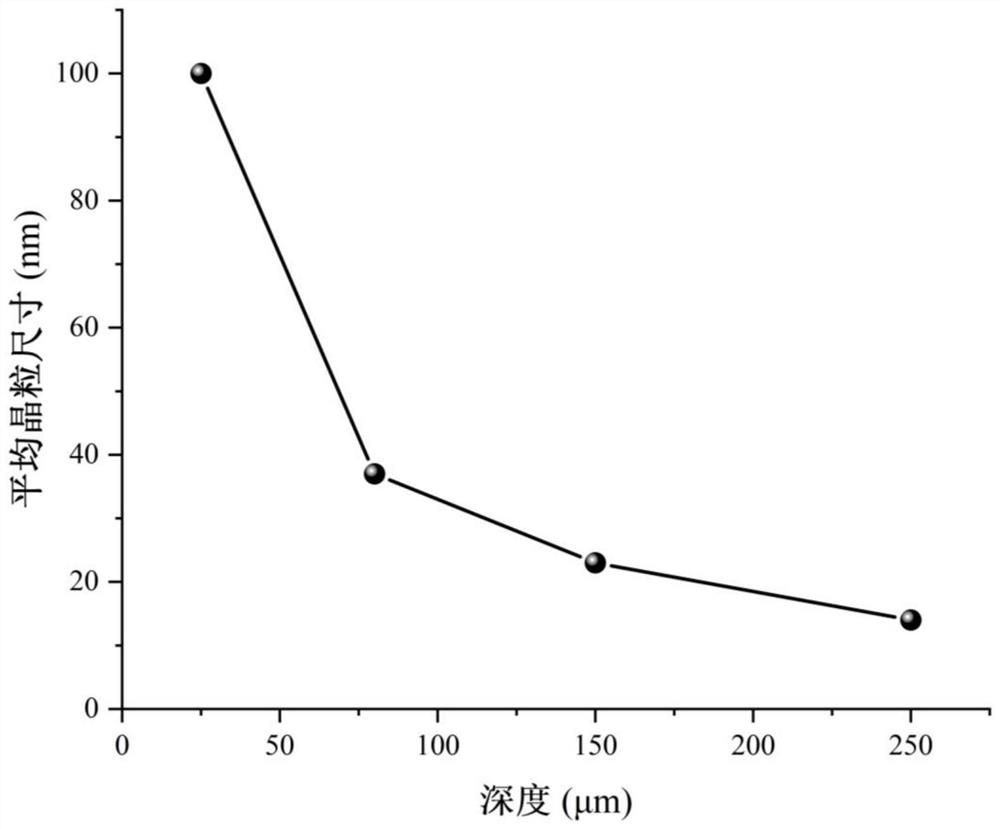

[0021] A. Through repeated cold rolling, the final thickness of the plate is 1mm, and the average grain size is about 14nm;

[0022] B, polishing all surfaces of the above-mentioned ultrafine nanocrystals to a mirror surface;

[0023] C. Surface scanning is carried out on the polished ultrafine nanocrystalline nickel-titanium substrate with a continuous laser power of 100W, the scanning speed is 1000mm / s, and the scanning line spacing is 30μm.

[0024] In step A, the ultrafine nanocrystalline nickel-titanium al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com