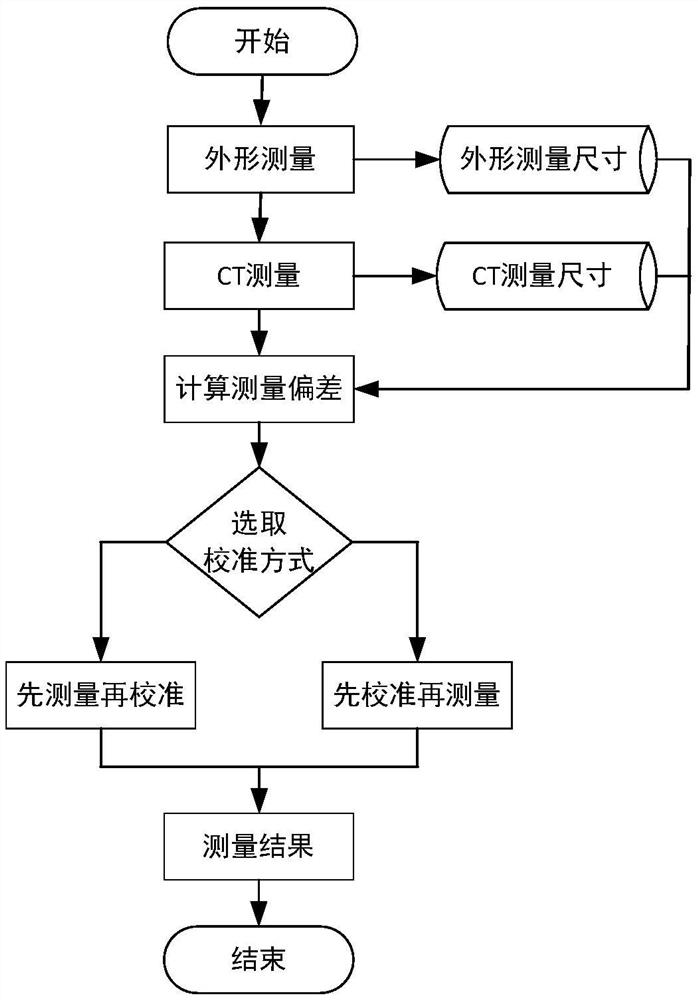

Method for calibrating CT measurement data by using profile measurement data

A technology for measuring data and shape, applied in the field of industrial CT non-destructive testing, can solve problems such as difficult traceability and complex sources of measurement errors, and achieve the effects of wide applicability, improved accuracy and reliability, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: For a titanium alloy 3D printed part, the part has external cylindrical features, and the diameter of an inner flow channel is measured by conventional focus industrial CT, and the method provided by the present invention is applied to perform the following steps:

[0029] Step 1: Select a vernier caliper with a nominal measurement accuracy of ±0.02mm, which is known to be higher than the measurement accuracy of the conventional focal industrial CT used. For the titanium alloy 3D printed part, use a vernier caliper to measure an external cylinder within its scanning area Diameter, the type of this geometric dimension is an entity class, denoted as S 1 ;

[0030] Step 2: Perform CT scan reconstruction on the part to obtain a tomographic image;

[0031] Step 3: Carry out image segmentation on the tomographic image to obtain CT point cloud data;

[0032] Step 4: According to the CT point cloud data, measure the geometric size of the corresponding part in st...

Embodiment 2

[0038] Embodiment 2: For a high-temperature alloy precision casting part, the part has the features of external cylinder, round hole and boss, and adopts small-focus industrial CT to measure the position of 9 round holes inside it, and applies the method provided by the present invention to perform the following step:

[0039] Step 1: Select a three-coordinate measuring machine with a nominal measurement accuracy of (3.7+L / 100) μm. It is known that the accuracy is higher than the small-focus industrial CT measurement accuracy used. For the high-temperature alloy precision casting parts, use three-coordinate The measuring machine measures 3 geometric dimensions within its scanning area, including a cylindrical diameter S 1 , a boss thickness S 2 , a circular hole diameter E 1 , where S 1 and S 2is the entity class size, E 1 is the cavity size;

[0040] Step 2: Perform CT scan reconstruction on the part to obtain a tomographic image;

[0041] Step 3: Carry out image segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com