Automatic control system for motorcycle cylinder block production line

An automatic control system and production line technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of large labor input and low production efficiency, avoid safety accidents, reduce errors, and achieve unmanned Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

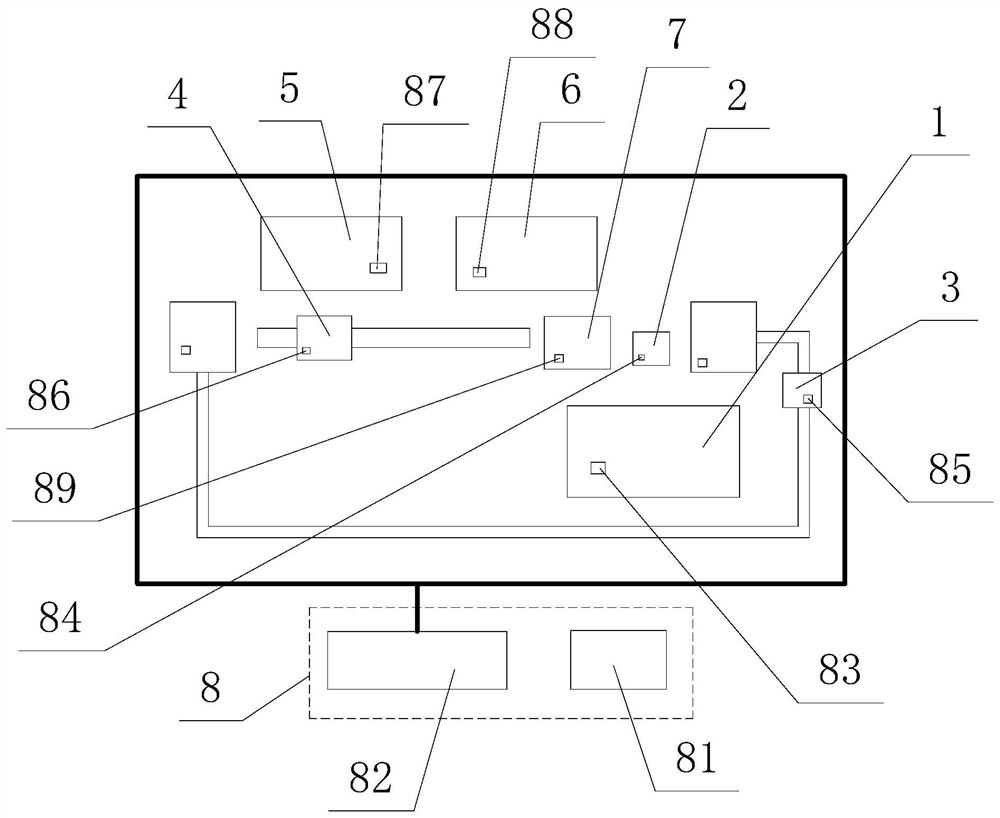

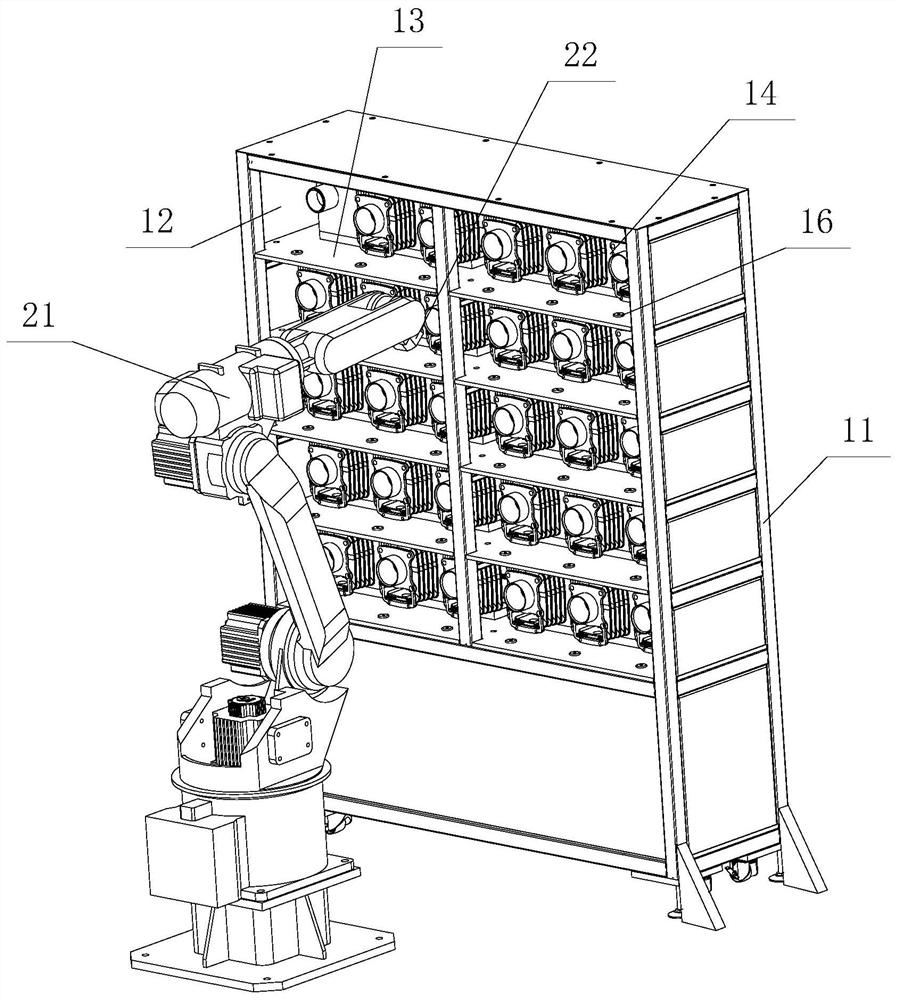

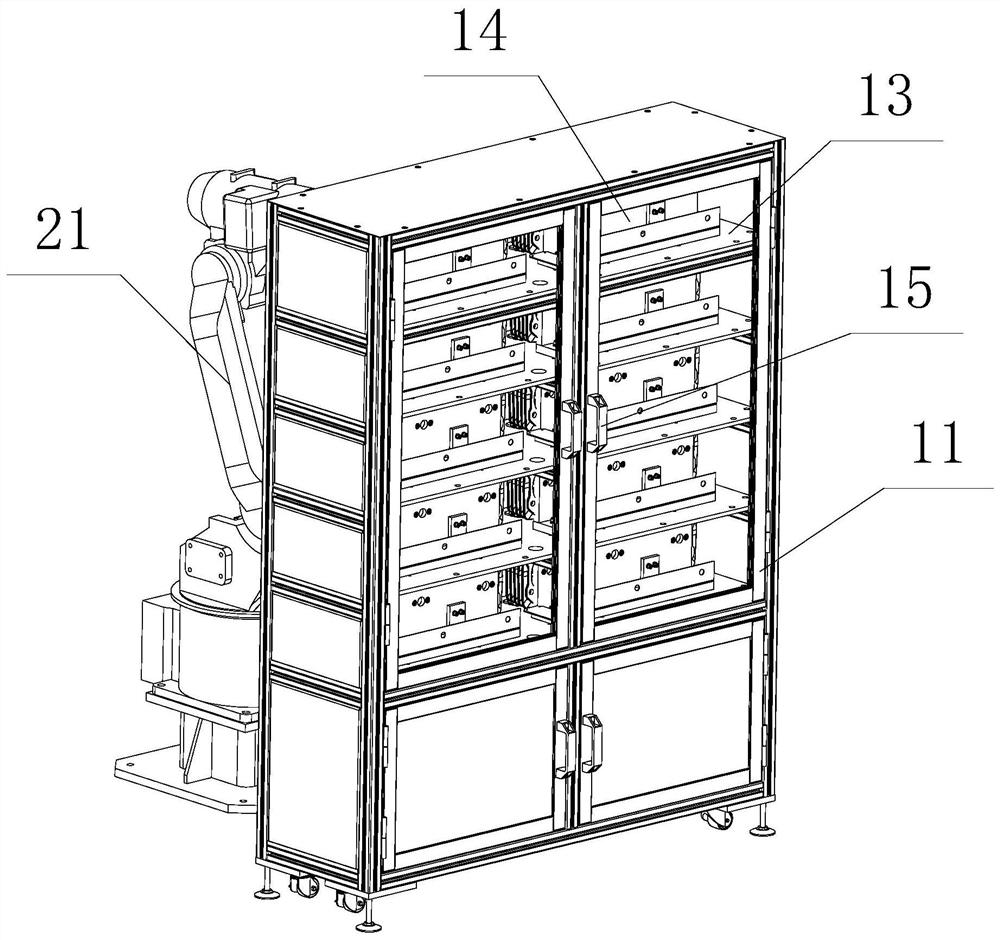

[0041] Such as Figure 1 ~ 13 As shown, the motorcycle cylinder production line provided by the present embodiment includes a discharge frame 14 for placing a cylinder, by providing a discharge frame 14, a cylinder is placed in a point to reduce artificial investment. At the same time, the discharge frame 14 can be used to store the processing completed cylinder to prevent automatic processing, and the processing completed cylinder is more caused by the product accumulation; the apparatus 2 is used to take the cylinder on the discharge frame 14. The tubing device 2 is taken out before processing, and then placed in a processed cylinder for realizing manual investment; feeding device 3 for will The cylinder taken out of the refrigeration device 2 is sent to the processing, and the feed device 3 is mainly used to take the cylinder to be processed by the cylinder to be processed to the processing, and the step of being processed, eliminating the step of manually transferring the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com