Method for improving arc extinguishing efficiency of multi-cavity structure by using magnetic field

A multi-chamber, magnetic field technology, applied in electrical components, spark gaps, spark gap parts, etc., can solve the problems of limited arc extinguishing capacity of chambers, tripping due to lightning strikes, and reducing tripping rate due to lightning strikes, so as to shorten the arc extinguishing time, The effect of reducing line faults and improving arc extinguishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

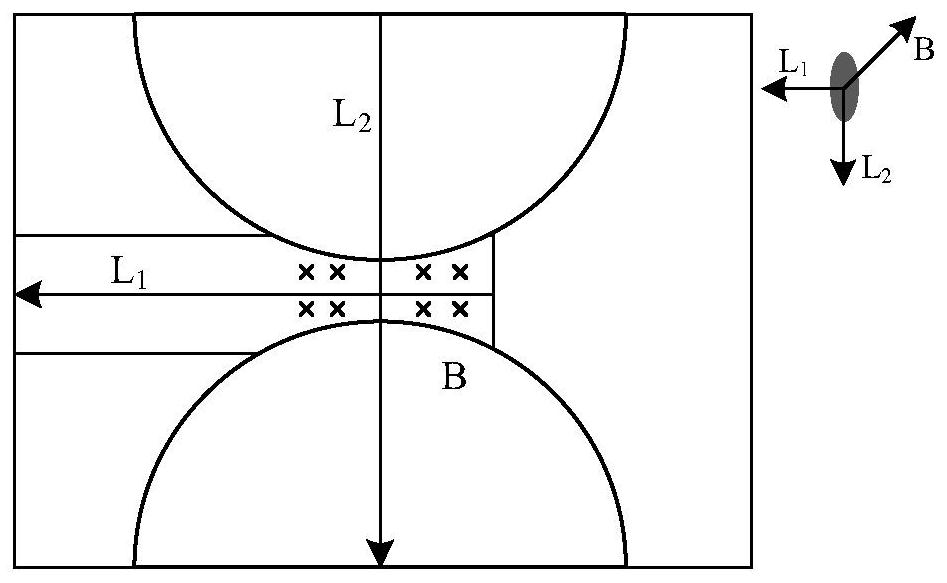

[0022] Such as figure 1 Shown is a schematic diagram of the time-varying magnetic field direction set in a single arc quenching chamber unit, where is the central axis towards which the nozzle in the quenching arc structure is directed, It is the connection line between the high and low pressure ball electrodes, the direction and vector of the magnetic field B Consistent, that is, perpendicular to the central axis facing the nozzle in the arc quenching structure and the line connecting the high and low pressure ball electrodes, and in this way, the arc plasma can be subjected to the Lorentz force in the magnetic field along the direction of the necking.

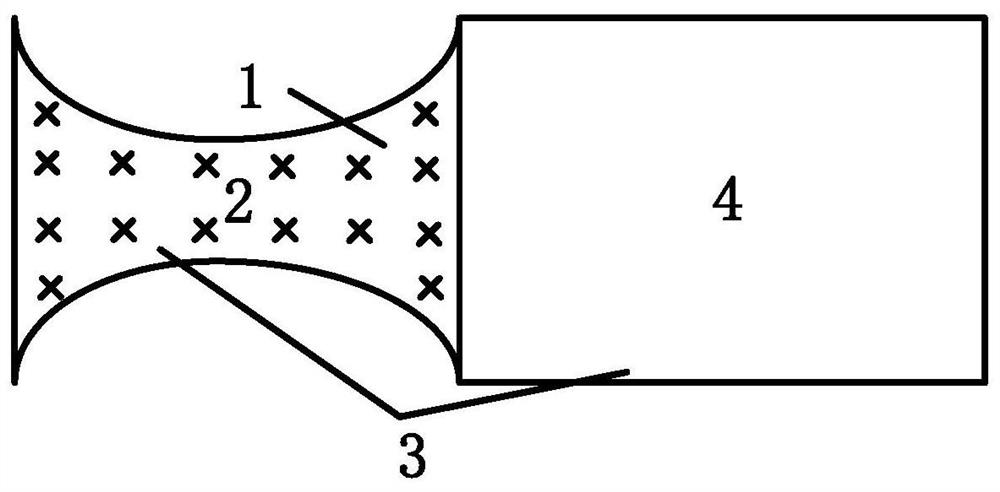

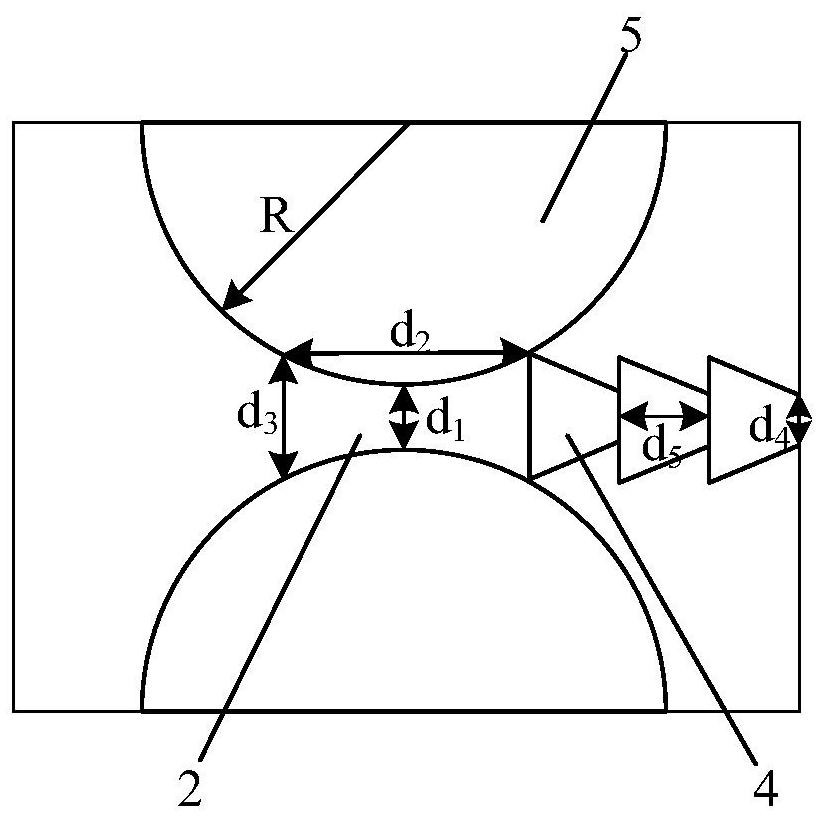

[0023] Such as figure 2 Shown is a schematic diagram of the magnetic field area set in this embodiment. The magnetic field area 1 mainly covers the discharge section 2 of the arc quenching structure, wherein the discharge section 2 refers to the air gap space 3 covering the discharge electrodes and the arc between the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com