Bimetal composite pipe and preparation method thereof

A bimetallic composite pipe and composite pipe technology, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of difficult preparation of stainless steel/nickel-based alloy composite pipes, and achieve the effects of low cost, excellent quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

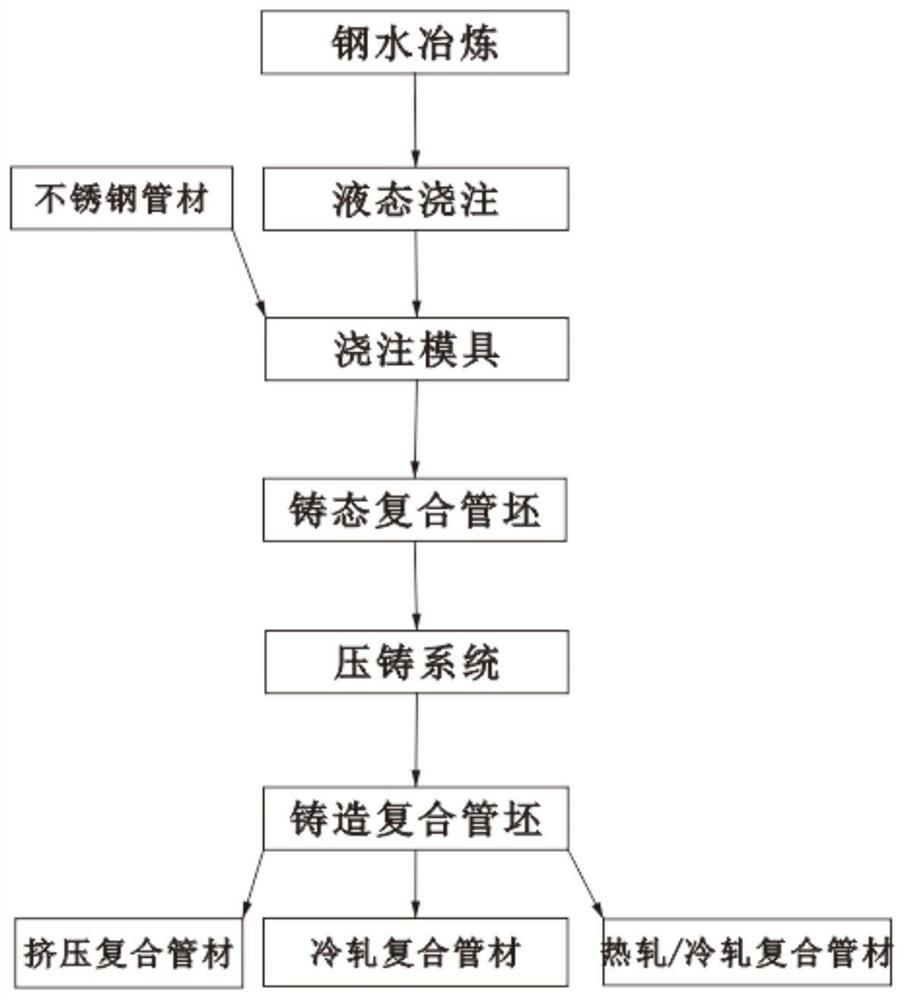

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a bimetal composite pipe, comprising the following steps:

[0035] S1: Pretreatment of 304 steel pipes, the pretreatment includes the following steps:

[0036] SS1: Soak 304 steel pipes in 0.1mol / L sodium hydroxide and 0.1mol / L hydrochloric acid solutions for 1 hour respectively, then rinse with deionized water for 3 times, and dry the water on the surface of the base steel pipe;

[0037] SS2: Put the 304 steel pipe after SS1 treatment into nickel ammonium sulfate at a temperature of 600°C, keep it warm for 60 minutes, and grow a binder film coating with a thickness of about 200nm on the surface of the base steel pipe in situ;

[0038] S2: Smelting the Q235 carbon steel to make it into molten steel, and adjusting the temperature of the molten steel to 1530°C; the target carbon steel smelting includes the following steps:

[0039] SS1: Take Q235 carbon steel and heat it to liquid state;

[0040] SS2: Transfer the liquid Q235 carbon steel to the c...

Embodiment 2

[0047] A method for preparing a bimetal composite pipe, comprising the following steps:

[0048] S1: Pretreatment of 304 steel pipes, the pretreatment includes the following steps:

[0049] SS1: Soak 304 steel pipes in 0.1mol / L sodium hydroxide solution and 0.1mol / L hydrochloric acid solution for 1 hour respectively, then rinse with deionized water for 4 times, and dry the water on the surface of the base steel pipe;

[0050] SS2: Put the 304 steel pipe after SS1 treatment into nickel ammonium sulfate at a temperature of 550°C, keep it warm for 45 minutes, and grow a binder film coating with a thickness of about 100nm on the surface of the base steel pipe in situ;

[0051] S2: Smelting the Q235 carbon steel to make it into molten steel, and adjusting the temperature of the molten steel to 1600°C; the target carbon steel smelting includes the following steps:

[0052] SS1: Take Q235 carbon steel and heat it to liquid state;

[0053] SS2: Transfer the liquid Q235 carbon steel ...

Embodiment 3

[0060] A method for preparing a bimetal composite pipe, comprising the following steps:

[0061] S1: Pretreatment of 304 steel pipes, the pretreatment includes the following steps:

[0062] SS1: Soak the 304 steel pipe in the sodium hydroxide solution with a concentration of 0.1mol / L and the hydrochloric acid solution with a concentration of 0.1mol / L for 1 hour respectively, then rinse it twice with deionized water, and then dry the water on the surface of the base steel pipe;

[0063] SS2: Put the 304 steel pipe after SS1 treatment into nickel ammonium sulfate at a temperature of 650°C, keep it warm for 45 minutes, and grow a binder film coating with a thickness of about 150nm on the surface of the base steel pipe in situ;

[0064] S2: Smelting the Q235 carbon steel to make it into molten steel, and adjusting the temperature of the molten steel to 1700°C; the target carbon steel smelting includes the following steps:

[0065] SS1: Take Q235 carbon steel and heat it to liquid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com