PVC baking varnish adhesive tape for metal baking varnish vehicle and preparation method of PVC baking varnish adhesive tape

A technology for metal baking varnishes and vehicles. It is applied in the direction of adhesives, natural rubber adhesives, and adhesive types. It can solve problems such as poor heat resistance, easy residual glue, and inconvenient cleaning, and achieve enhanced heat resistance. Small diffusion, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

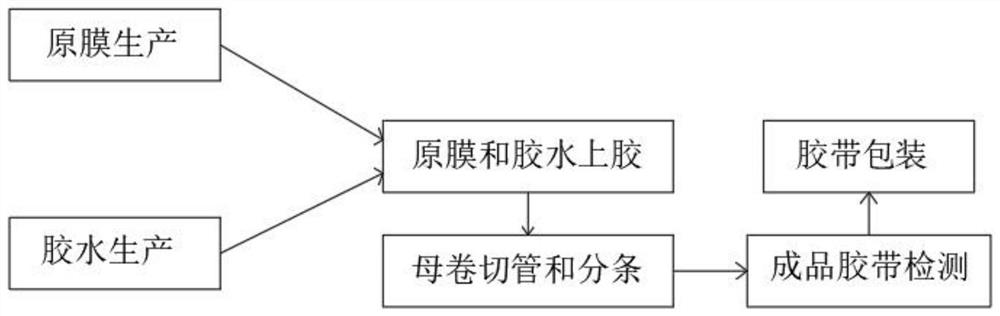

Method used

Image

Examples

Embodiment 1

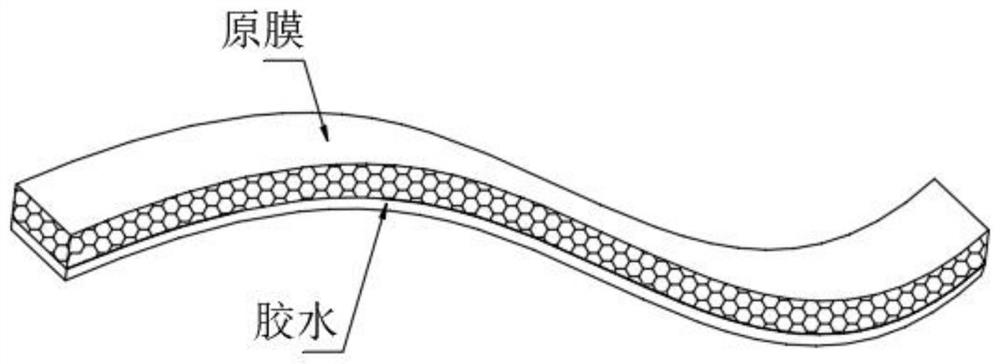

[0035] The PVC baking varnish adhesive tape for metal baking varnish vehicles includes an original film and glue, the bottom of the original film is provided with glue, the glue and the original film are bonded, and the area of the bottom surface of the original film matches the area of the glue. The thickness of the original film is greater than that of the glue.

[0036] Further, the composition of the original film formula: 50-60% vinyl chloride resin (PVC), 15-18% plasticizer, 20-25% filler, 0.21-0.28% stabilizer, 0.9-1.3% Gelling accelerator and 0.15-0.21% antioxidant.

[0037] Further, the composition of the glue formula: 18-22% of natural rubber, 25-31% of styrene-butadiene rubber, 5-8% of synthetic rubber, 25-31% of terpene resin, 20-22% of hydrogenated resin , 1.5-3.1% liquid phenolic resin and 0.08-0.1% antioxidant.

[0038] Further, the selected plasticizers are dioctyl phthalate, trioctyl trimellitate and polyethylene terephthalate, and dioctyl phthalate, tri...

Embodiment 2

[0058] The PVC baking varnish adhesive tape for metal baking varnish vehicles includes an original film and glue, the bottom of the original film is provided with glue, the glue and the original film are bonded, and the area of the bottom surface of the original film matches the area of the glue. The thickness of the original film is greater than that of the glue.

[0059] Further, the composition of the original film formula: 55% vinyl chloride resin (PVC), 16.5% plasticizer, 22.5% filler, 0.245% stabilizer, 0.11% gelling accelerator and 0.18% Antioxidants.

[0060] Further, the glue formula consists of: 20% natural rubber, 28% styrene-butadiene rubber, 6.5% synthetic rubber, 28% terpene resin, 21% hydrogenated resin, 2.3% liquid phenolic resin and 0.09% of antioxidants.

[0061] Further, the selected plasticizers are dioctyl phthalate, trioctyl trimellitate and polyethylene terephthalate, and dioctyl phthalate, trioctyl trimellitate The ratio of octyl ester to polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com