Supersonic speed test cabin for plane cascade high-altitude flow simulation

A flow simulation and supersonic technology, which is applied in engine testing, jet engine testing, gas turbine engine testing, etc., can solve the problems of lack of flow field quality improvement means, single test Reynolds number simulation means, and limited range, so as to save tests Preparation time, simple test preparation, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

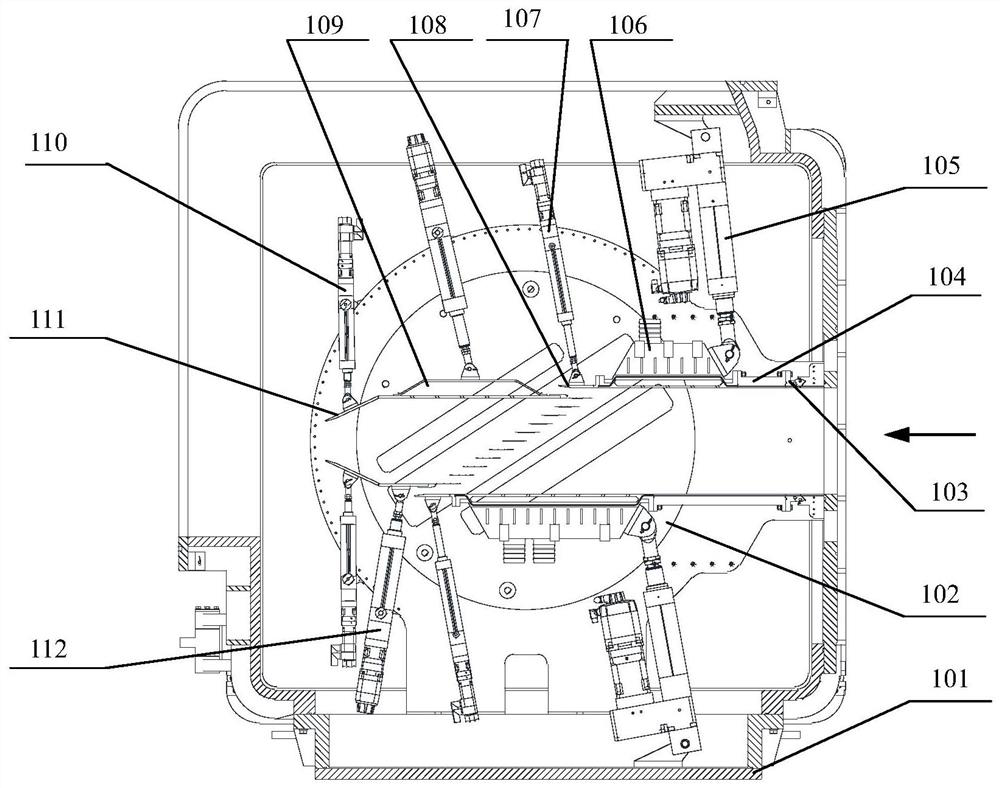

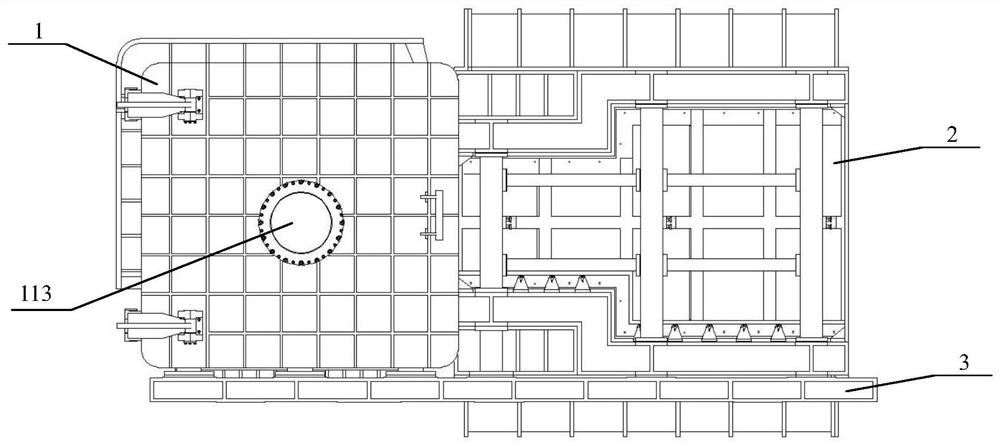

[0033] Such as figure 2 As shown, the supersonic test cabin 1 used for plane cascade high-altitude flow simulation in this embodiment is installed on the installation platform 3, and the variable Mach number nozzle 2 and the supersonic test cabin 1 are sequentially connected along the airflow direction on the installation platform 3; A cascade test piece is installed in the supersonic speed test cabin 1 , and an observation window 113 is installed in the center of the left and right side walls of the supersonic speed test cabin 1 .

[0034] The variable Mach number nozzle 2 is a two-dimensional square nozzle, which has a sub-transonic nozzle profile adjustment function with a Mach number of 1.0 to Mach number 2.0, and is used to adjust the incoming Mach number of the supersonic test chamber 1 .

[0035] The flow field calibration test shows that the deviation of the core area of the flow field in the test section of the supersonic test chamber 1 is better than 0.01 when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap