Two-dimensional magnetic Fe3GeTe2 nanosheet and graphene nanosheet composite material as well as preparation method and application thereof

A technology of graphene nanosheets and composite materials, which is applied in the field of wave-absorbing materials, can solve the problems of not being able to meet the reflection loss value, hinder the development of wave-absorbing materials, and low thickness at the same time, and achieve good dispersion effect, low power, and high power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

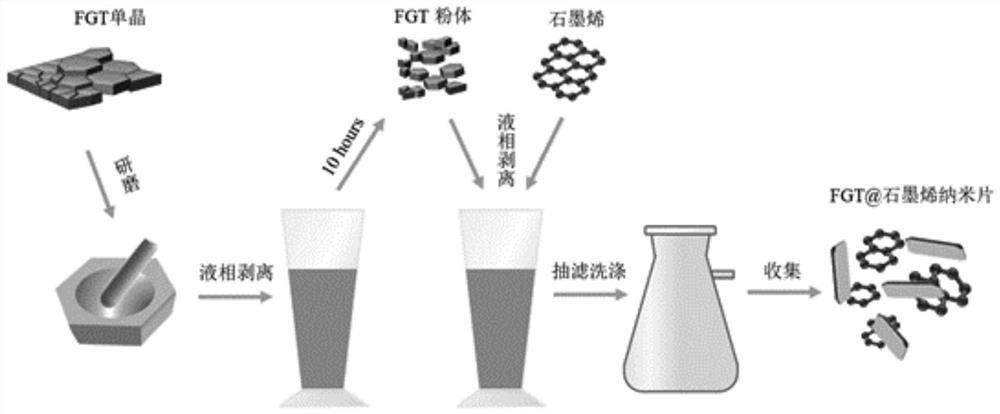

[0042] This embodiment provides a two-dimensional magnetic Fe 3 GeTe 2 Nano sheet and graphene nano sheet composite material, the flow process of its preparation method is as follows figure 1 As shown, it specifically includes the following steps:

[0043] (1) Grinding Fe 3 GeTe 2 single crystal, obtained Fe 3 GeTe 2 Powder; the Fe 3 GeTe 2 The powder was added into acetone (1mg / mL), and the ultrasonic liquid phase exfoliation was performed for 10 hours, and the power of the ultrasonic liquid phase exfoliation was 500W to obtain Fe 3 GeTe 2 nanosheet dispersion.

[0044] (2) Fe was collected by vacuum filtration and washed with deionized water 3 GeTe 2 nanosheets, dried under vacuum to obtain Fe 3 GeTe 2 Nanosheets.

[0045] (3) Graphite and Fe 3 GeTe 2 The nanosheets were evenly mixed according to the mass ratio of 1:1~3, and added to NMP (1-methyl-2-pyrrolidone) according to a certain mass ratio (1mg / mL), and ultrasonically dissociated in liquid phase for 2 h...

Embodiment 2

[0051] This embodiment provides a two-dimensional magnetic Fe 3 GeTe 2 Nano sheet and graphene nano sheet composite material, the flow process of its preparation method is as follows figure 1 As shown, it specifically includes the following steps:

[0052] (1) Grinding Fe 3 GeTe 2 single crystal, obtained Fe 3 GeTe 2 Powder; the Fe 3 GeTe 2 The powder was added to acetone (1.5mg / mL), and the ultrasonic liquid phase exfoliation was performed for 15 hours. The power of the ultrasonic liquid phase exfoliation was 600W, and Fe 3 GeTe 2 nanosheet dispersion.

[0053] (2) Fe was collected by vacuum filtration and washed with deionized water 3 GeTe 2 nanosheets, dried under vacuum to obtain Fe 3 GeTe 2 Nanosheets;

[0054] (3) Graphite and Fe 3 GeTe 2 The nanosheets were uniformly mixed according to the mass ratio of 1:2, and added to NMP (1-methyl-2-pyrrolidone) according to a certain mass-volume ratio (1.5 mg / mL), and ultrasonically dissociated in liquid phase for 4...

Embodiment 3

[0057] This embodiment provides a two-dimensional magnetic Fe 3 GeTe 2 Nano sheet and graphene nano sheet composite material, the flow process of its preparation method is as follows figure 1 As shown, it specifically includes the following steps:

[0058] (1) Grinding Fe 3 GeTe 2 single crystal, obtained Fe 3 GeTe 2 Powder; the Fe 3 GeTe 2 The powder was added to acetone (0.5mg / mL), and the ultrasonic liquid phase exfoliation was carried out for 9 hours. The power of the ultrasonic liquid phase exfoliation was 400W, and Fe 3 GeTe 2 nanosheet dispersion.

[0059] (2) Fe was collected by vacuum filtration and washed with deionized water 3 GeTe 2 nanosheets, dried under vacuum to obtain Fe 3 GeTe 2 Nanosheets;

[0060] (3) Graphite and Fe 3 GeTe 2 The nanosheets were uniformly mixed according to the mass ratio of 1:2, and added to NMP (1-methyl-2-pyrrolidone) according to a certain mass-volume ratio (0.5 mg / mL), and ultrasonically dissociated in liquid phase for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reflection loss value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum reflection loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com