Treatment process for stable dehydration of ammonia-alkali process alkali residues

A treatment process, the technology of the ammonia-soda method, which is applied in the field of stable dehydration of the ammonia-soda method alkali slag, which can solve the problems of high cost, poor cohesion, and loose structure, so as to reduce the treatment cost and realize reuse , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

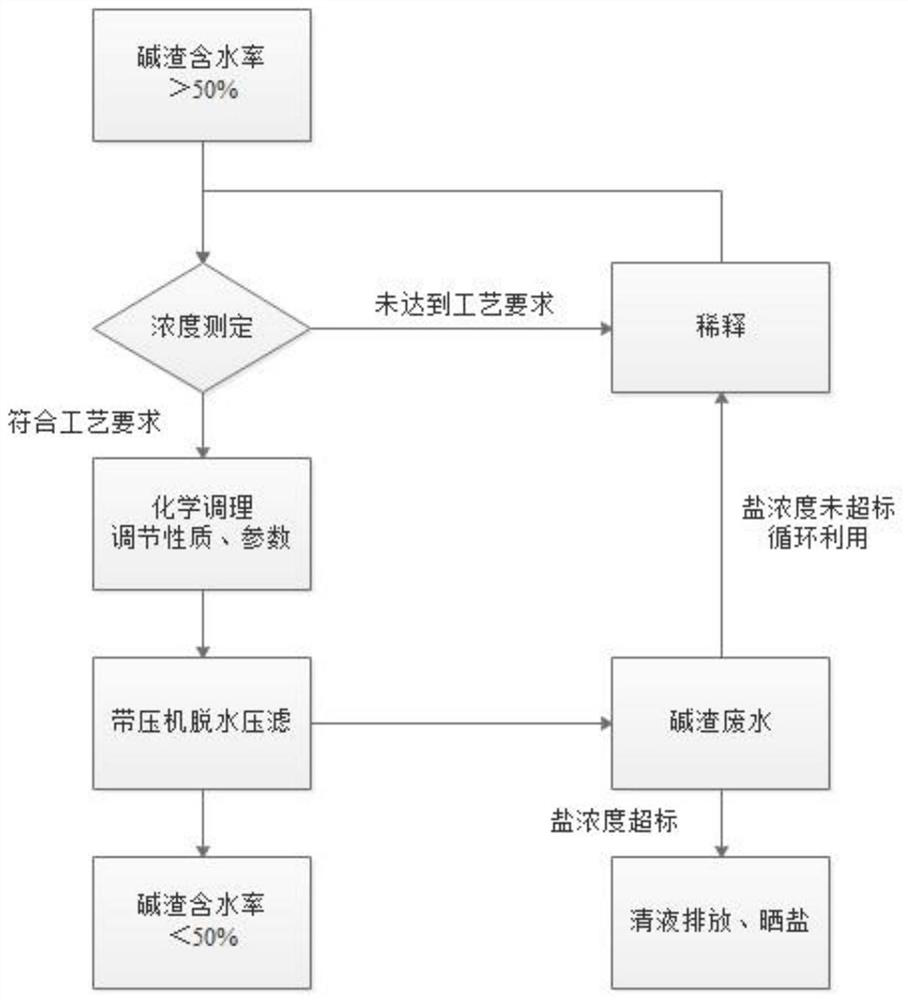

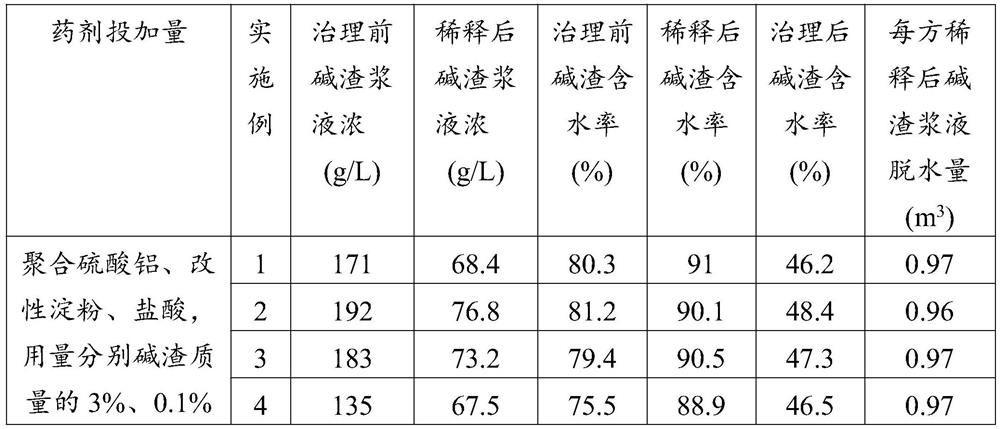

[0032] A process for stably dehydrating the ammonia-soda process alkali slag, the steps are as follows:

[0033] (1) measure the alkali slag concentration of the alkali slag slurry in the alkali slag pool to be 171g / L, wherein the water content in the slurry is 80.3%;

[0034] (2) Dilute the alkali slag slurry, and the diluted alkali slag concentration is 68.4g / L;

[0035] (3) in the diluted alkali slag slurry, add chemical conditioning agent and fully mix, and described chemical conditioning agent is the hydrochloric acid solution that mass concentration is 31% of polyaluminum sulfate, phosphoric acid type amphoteric starch, and consumption is respectively 3% of alkali slag quality %, 0.1% and 5%;

[0036] (4) Carry out belt filter press dehydration to the alkali slag slurry processed by chemical conditioning agent, record the alkali slag moisture content to be 46.2%, the dehydration clear liquid is returned to the alkali slag pond, and the alkali slag slurry in the alkali s...

Embodiment 2

[0038] A process for stably dehydrating the ammonia-soda process alkali slag, the steps are as follows:

[0039] (1) the alkali slag concentration of the alkali slag slurry in the alkali slag pond is measured to be 192g / L, wherein the water content in the slurry is 81.2%;

[0040] (2) Dilute the alkali slag slurry, and the diluted alkali slag concentration is 76.8g / L;

[0041] (3) In the diluted alkali slag slurry, add a chemical conditioner and fully mix. The chemical conditioner is polyaluminum sulfate, phosphoric acid type amphoteric starch, and a hydrochloric acid solution with a mass concentration of 31%, and the consumption is 3% of the alkali slag quality respectively. , 0.1% and 5%;

[0042] (4) Carry out belt filter press dehydration to the alkali slag slurry processed by chemical conditioning agent, record the alkali slag moisture content of 48.4%, the dehydration clear liquid is discharged back to the alkali slag pond, and the alkali slag slurry in the alkali slag po...

Embodiment 3

[0044] A process for stably dehydrating the ammonia-soda process alkali slag, the steps are as follows:

[0045] (1) measure the alkali residue concentration of the alkali residue slurry in the alkali residue pool to be 183g / L, wherein the water content in the slurry is 79.4%;

[0046] (2) Dilute the alkali slag slurry, and the diluted alkali slag concentration is 73.2g / L;

[0047] (3) In the diluted alkali slag slurry, add a chemical conditioner and fully mix. The chemical conditioner is polyaluminum sulfate, phosphoric acid type amphoteric starch, and a hydrochloric acid solution with a mass concentration of 31%, and the consumption is 3% of the alkali slag quality respectively. , 0.1% and 5%;

[0048] (4) Carry out belt filter press dehydration to the alkali slag slurry processed by chemical conditioning agent, record the alkali slag moisture content to be 47.3%, the dehydration clear liquid is discharged back to the alkali slag pond, to the alkali slag slurry in the alkal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com