Wet desulfurization and denitrification integrated device and method for ship exhaust gas

A desulfurization, denitrification, and wet desulfurization technology, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of gypsum covering a large area, low reduction selectivity, and secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

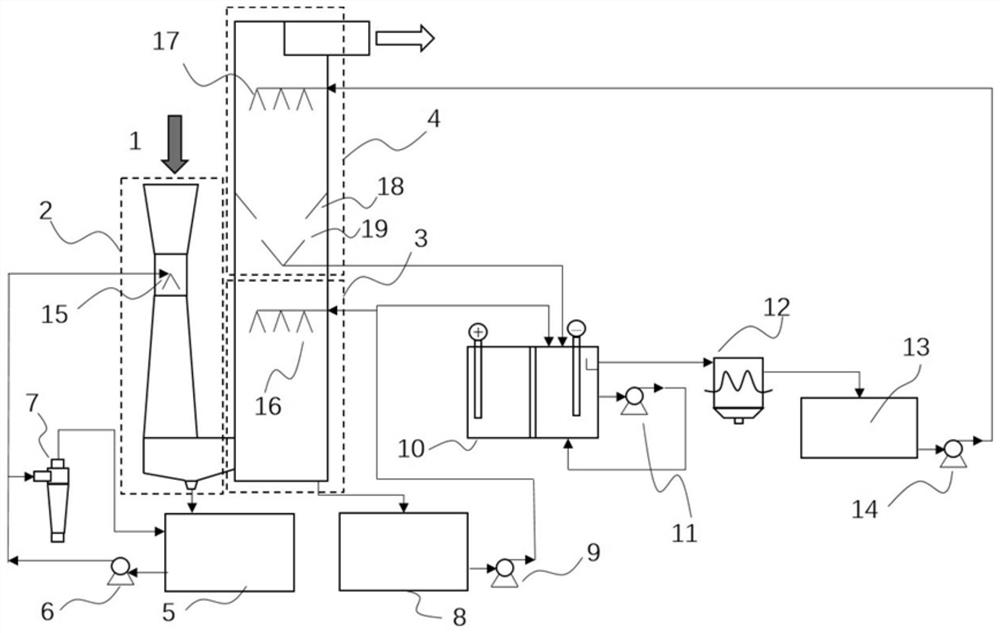

[0034] A method of desulfurizing denitrifting debris denitriftering debris deinterpulfurization denitriftering debris deinterlean deinterpretering, including the following steps:

[0035] (1) Ship exhaust (SO 2 Concentration 600ppm, no x 1100ppm, traffic 5000nm 3 / h) After the exhaust gas inlet 1 enters the first stage washing and dust removal zone 2, the first-stage washing dust removal zone 2 Liquid gas ratio is 2 l / nm 3 Partially circulated washing liquid is treated with solid liquid separator 7, and the concentrate is stored in the sludge tank, and the liquid is refluxed to the primary circulation pool 5, extracts the outboard seawater hydration;

[0036] (2) After removing dust, the exhaust gas enters the secondary washing desulfurization region 3, control the secondary washing desulfurization region 3 liquid gases is 4 l / nm 3 , By adding magnesium hydroxide to the secondary circulation pool 8, the pH of the second-stage washing desulfurization region 3 circulating spray...

Embodiment 2

[0041] A method of desulfurizing denitrifting debris denitriftering debris deinterpulfurization denitriftering debris deinterlean deinterpretering, including the following steps:

[0042] (1) Ship exhaust (SO 2 Concentration 600ppm, no x 1100ppm, traffic 5000nm 3 / h) After the exhaust gas inlet 1 enters the first stage washing and dust removal zone 2, the first-stage washing dust removal zone 2 Liquid gas ratio is 2 l / nm 3 Partially circulated washing liquid is treated with solid liquid separator 7, and the concentrate is stored in the sludge tank, and the liquid is refluxed to the primary circulation pool 5, extracts the outboard seawater hydration;

[0043] (2) After removing dust, the exhaust gas enters the secondary washing desulfurization region 3, control the secondary washing desulfurization region 3 liquid gases is 4 l / nm 3 , By adding magnesium hydroxide to the secondary circulation pool 8, the pH of the second-stage washing desulfurization region 3 circulating spray...

Embodiment 3

[0048] A method of desulfurizing denitrifting debris denitriftering debris deinterpulfurization denitriftering debris deinterlean deinterpretering, including the following steps:

[0049] (1) Ship exhaust (SO 2 Concentration 600ppm, no x 1100ppm, traffic 5000nm 3 / h) After the exhaust gas inlet 1 enters the first stage washing and dust removal zone 2, the first-stage washing dust removal zone 2 Liquid gas ratio is 2 l / nm 3 Partially circulated washing liquid is treated with solid liquid separator 7, and the concentrate is stored in the sludge tank, and the liquid is refluxed to the primary circulation pool 5, extracts the outboard seawater hydration;

[0050] (2) After removing dust, the exhaust gas enters the secondary washing desulfurization region 3, control the secondary washing desulfurization region 3 liquid gases is 4 l / nm 3 , By adding magnesium hydroxide to the secondary circulation pool 8, the pH of the second-stage washing desulfurization region 3 circulating spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com