Tensile high-strength hook forge piece forging device

A high-strength, hook-head technology, used in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve the problem of reducing the service life of the hook, increasing the shear force between the hook head and the structure, manual overturning and positioning uncontrollable progress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

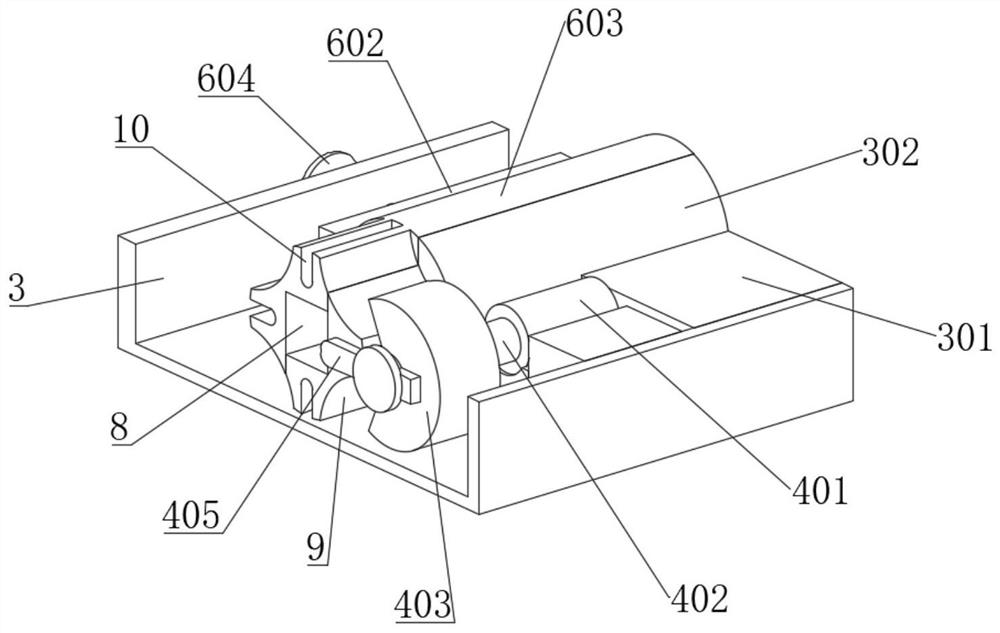

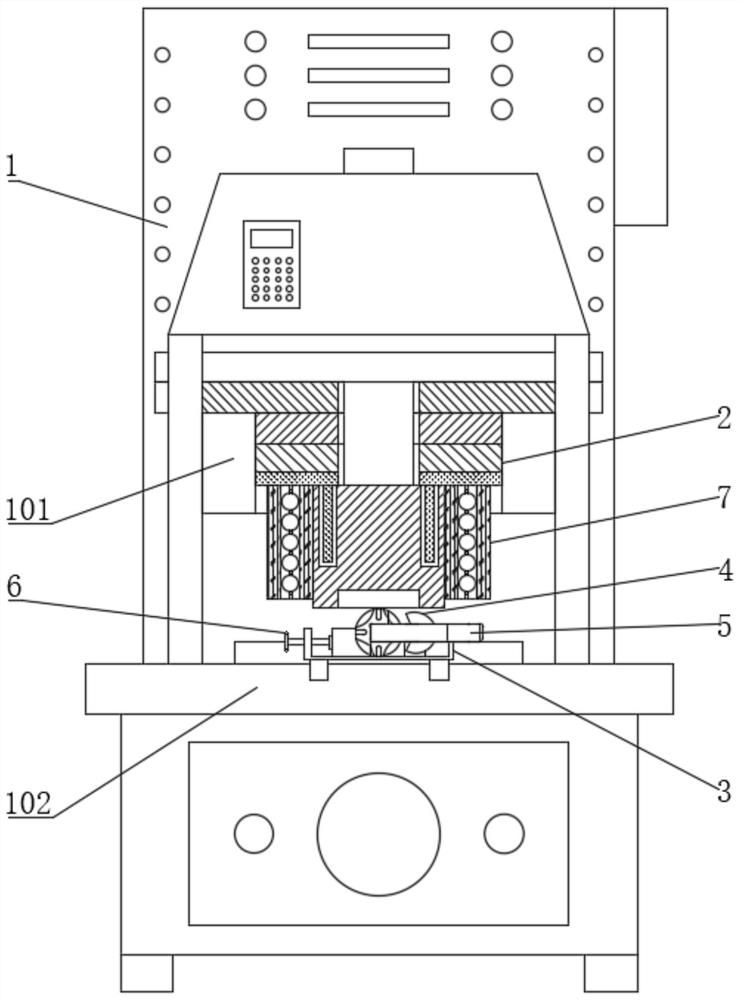

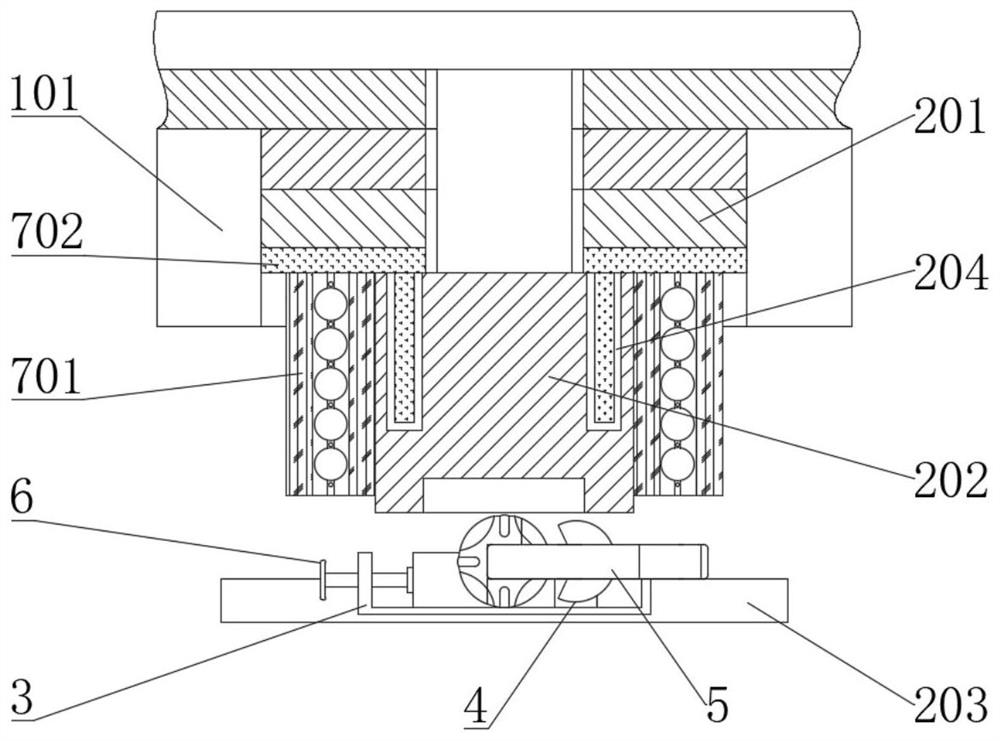

[0058] see Figure 1-13 , a high-strength tensile hook forging forging device, including a forging body 1, the upper end of the forging body 1 is fixedly connected with a mold mounting frame 101, and the upper end of the forging body 1 is fixedly connected with a forging frame located at the lower side of the mold mounting frame 101. Workbench 102, the forging mold 2 is installed in the mold mounting frame 101, the front end of the forging workbench 102 is fixedly installed with the forging holder 3 matching the forging mold 2, and the upper end of the forging holder 3 is fixedly connected with a fixed Arc block 301, the upper end of the forging clamp seat 3 is connected with the flip assembly 4 located at the front side of the fixed arc block 301, the upper end of the forged clamp seat 3 is connected with the clamping assembly 6 located on the left side of the fixed arc block 301, the clamp A hook 5 is installed between the holding assembly 6 and the fixed arc block 301; plea...

Embodiment 2

[0066] see Figure 1-13 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 and image 3 , the lower end of the mold mounting frame 101 is fixedly installed with a heating assembly 7, and the heating assembly 7 includes a heating sheath 701, and the left and right inner walls of the mold mounting frame 101 are fixedly connected with a heating sheath 701, and the forging punch 202 is located between the two heating jackets 701 and matches with the heating jackets 701 . The heating sheath 701 heats up the forging punch 202, reduces the generation of oxide skin on the end surface of the hook 5 caused by the temperature difference of the forging punch 202, improves the forging quality of the hook 5, homogenizes the cryst...

Embodiment 3

[0071] see Figure 1-13 , wherein the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 are described below. The difference between this embodiment 3 and embodiment 1 is: please refer to Figure 13 , a method for using a tensile high-strength hook head forging device, comprising the following steps:

[0072] S1. Place the formed hook 5 on the upper end of the forged holder 3;

[0073] S2. Turn the locking threaded rod 601 to drive the locking slider 602 and the clamping left rod 603 to move to the fixed arc block 301, and clamp and fix the hook 5;

[0074] S3. The forging body 1 drives the forging die 2 to act on the hook 5 to forge the hook head of the hook 5;

[0075] S4. After forging once, start the turning component 4, and drive the hook 5 to turn over on the forging holder 3;

[0076] S5. Repeat steps S3-S4;

[0077] S6. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com