Sludge hydrothermal humic acid generation regulation and heavy metal passivation method

A technology of humic acid and sludge water, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve mosquito breeding and long composting time (generally within 20 days) The above problems, such as large area, achieve the effect of reducing bioavailability, promoting the degree of humification, and achieving stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

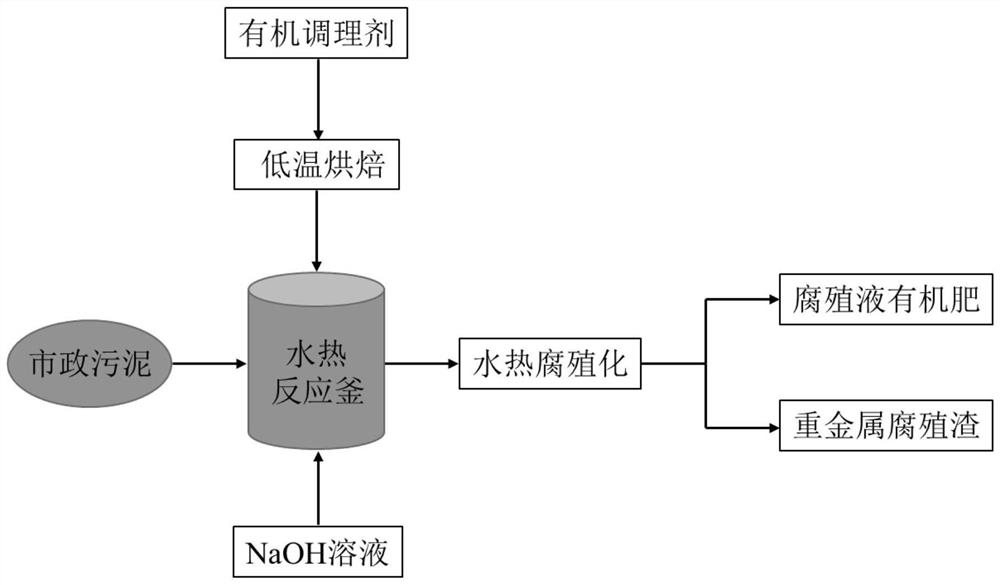

Method used

Image

Examples

Embodiment 1

[0024] (1) Pretreatment of municipal sludge: Take the remaining sludge from a sewage treatment plant in Wuxi, let it dry naturally for 48 hours, dry it at 105°C for 12 hours, and pass it through a 35-mesh molecular sieve after crushing; the industrial analysis value of the volatile content of the municipal sludge is greater than 45%;

[0025] (2) Pretreatment of the organic conditioner: the organic conditioner is subjected to low-temperature roasting treatment, the roasting temperature is 150° C., and the roasting time is 0.5 h; wherein the organic conditioner is a lignin-based organic conditioner;

[0026] (3) Get 4.0g municipal sludge, 1.0g organic conditioner, mix them evenly and add in the hydrothermal reaction kettle of 100mL capacity, add the sodium hydroxide solution of 70mL pH=8 (sodium hydroxide solution concentration is 10 -6 mol / L, the pH value is 8);

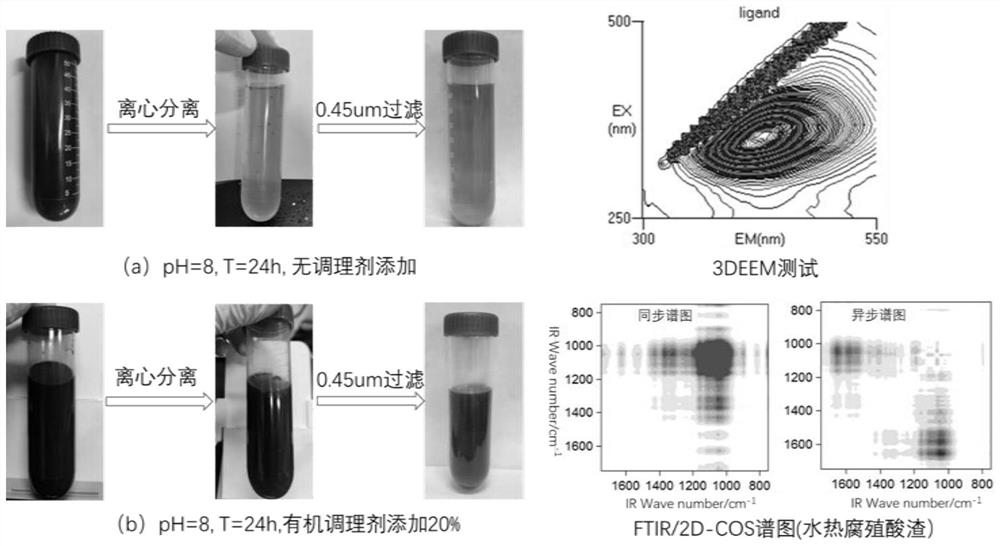

[0027] (4) Hydrothermal humification reaction: set the hydrothermal humification reaction temperature to 250°C, t...

Embodiment 2

[0030] The difference between this embodiment and specific example 1 is that the added amount of the organic conditioner is 0 g.

[0031] (1) Pretreatment of municipal sludge: Take the remaining sludge from a sewage treatment plant in Wuxi, let it dry naturally for 48 hours, dry it at 105°C for 12 hours, and pass it through a 35-mesh molecular sieve after crushing; the industrial analysis value of the volatile content of the municipal sludge is greater than 45%;

[0032] (2) Pretreatment of the organic conditioner: the organic conditioner is subjected to low-temperature roasting treatment, the roasting temperature is 150° C., and the roasting time is 0.5 h; wherein the organic conditioner is a lignin-based organic conditioner;

[0033] (3) Get 4.0g of municipal sludge, add it to a hydrothermal reaction kettle with a capacity of 100mL, add 70mL of sodium hydroxide solution with pH=8 (the concentration of sodium hydroxide solution is 10 -6 mol / L, the pH value is 8);

[0034] (...

Embodiment 3

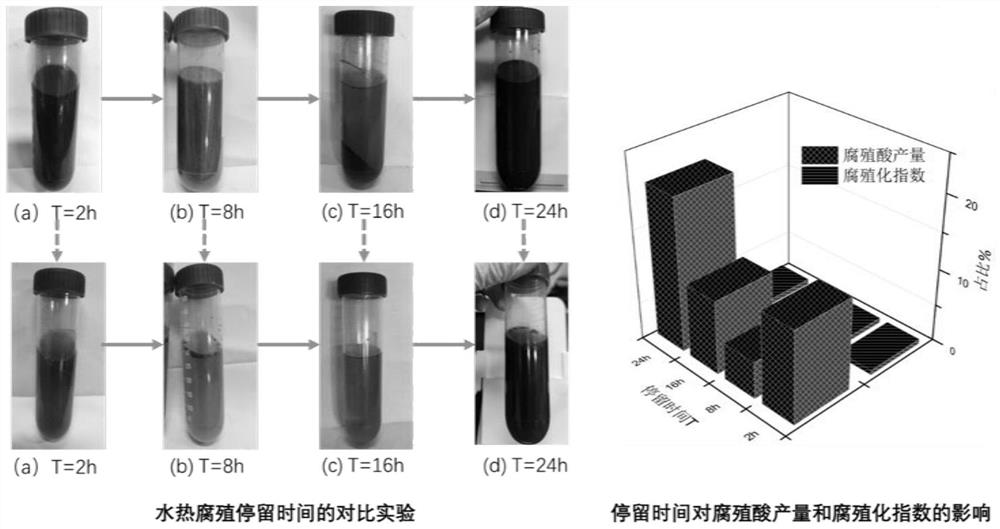

[0037] The difference between this embodiment and the specific example 1 is that the hydrothermal humification reaction time is 2 hours.

[0038] (1) Pretreatment of municipal sludge: Take the remaining sludge from a sewage treatment plant in Wuxi, let it dry naturally for 48 hours, dry it at 105°C for 12 hours, and pass it through a 35-mesh molecular sieve after crushing; the industrial analysis value of the volatile content of the municipal sludge is greater than 45%;

[0039] (2) Pretreatment of the organic conditioner: the organic conditioner is subjected to low-temperature roasting treatment, the roasting temperature is 150° C., and the roasting time is 0.5 h; wherein the organic conditioner is a lignin-based organic conditioner;

[0040] (3) Get 4.0g municipal sludge, 1.0g organic conditioner, mix them evenly and add in the hydrothermal reaction kettle of 100mL capacity, add the sodium hydroxide solution of 70mL pH=8 (sodium hydroxide solution concentration is 10 -6 mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com