Porous polydimethylsiloxane with daytime radiation refrigeration function, and preparation method thereof

A dimethylsiloxane, radiative cooling technology for sustainable manufacturing/processing, sustainable construction, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a preparation method of porous polydimethylsiloxane with daytime radiation refrigeration, comprising the following steps:

[0035] (1) Synthesis of micron NaCl porogen:

[0036] Add 5ml, 3M NaCl solution (solvent is water) dropwise to 100ml of absolute ethanol under stirring condition, stir for 10min, stop stirring, after standing for 1min, pour off the supernatant, and use a centrifuge to centrifuge , collect the white precipitate; wash the white precipitate with absolute ethanol, centrifuge with a centrifuge to collect the precipitate, put the precipitate in a vacuum drying oven at 100°C for 12 hours and take it out, grind it to powder with agate smoke wave, A micron-sized NaCl porogen with a particle size of 7.5 μm was obtained;

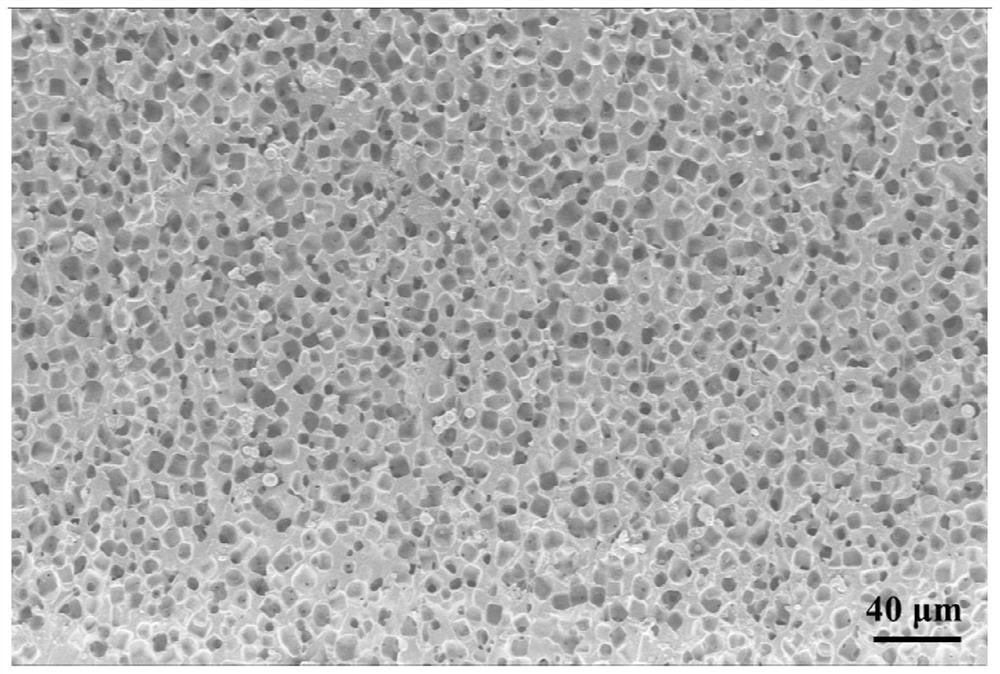

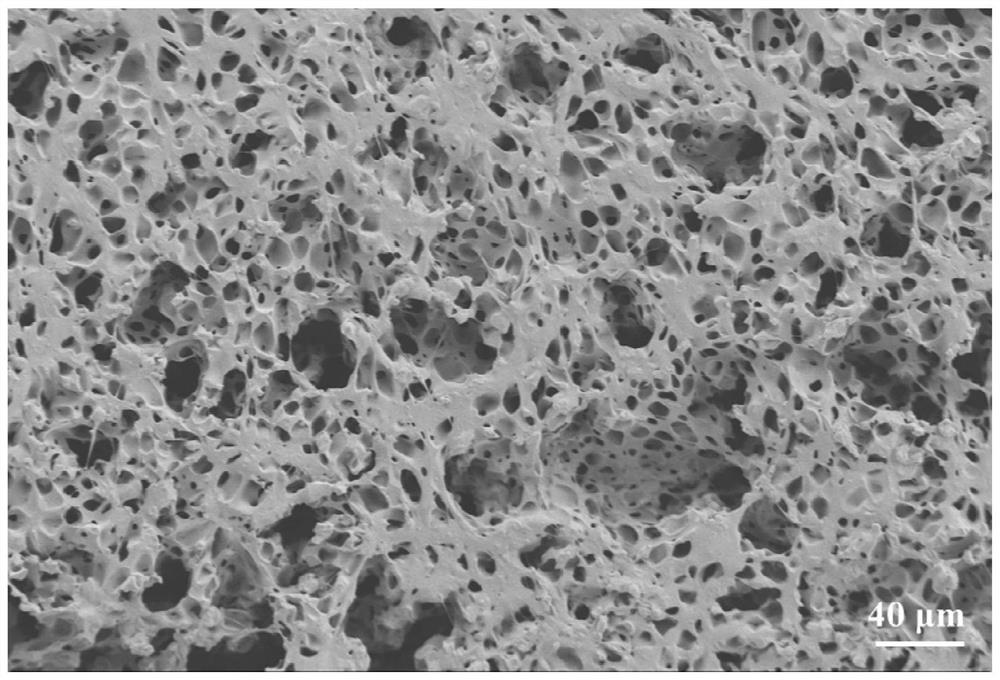

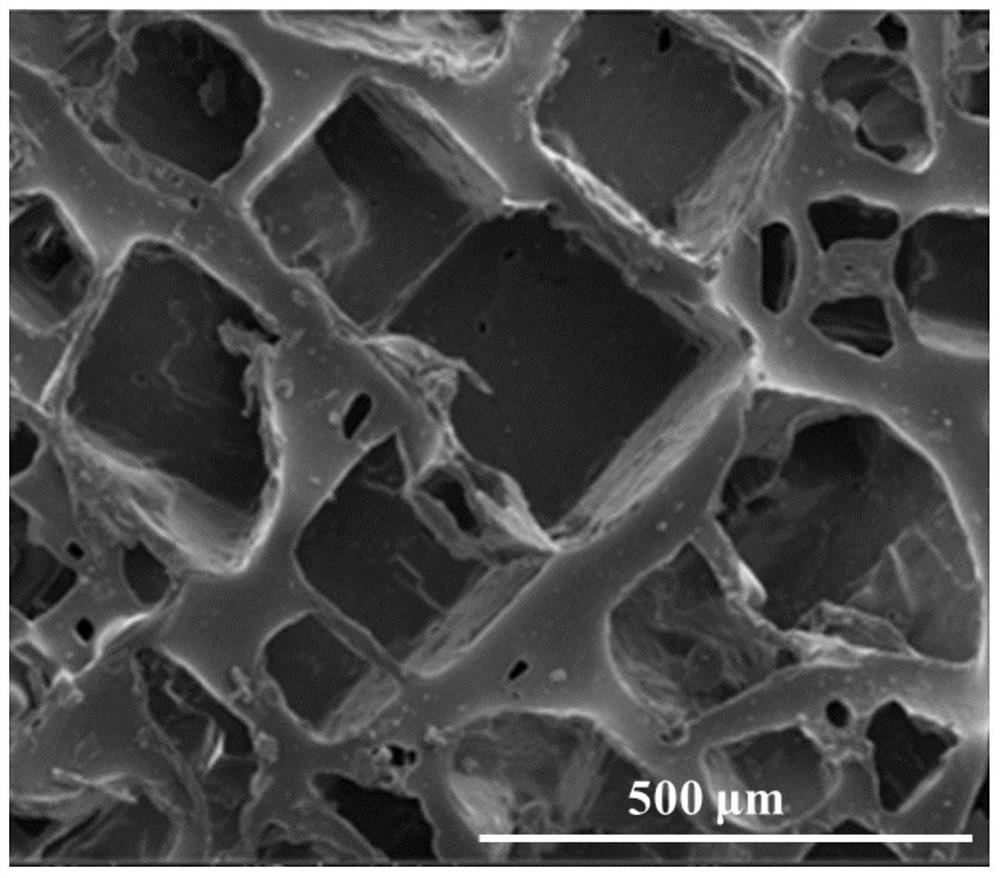

[0037] (2) Weigh 10g of Dow Corning PDMS (Dow Corning 184A) and 2g of Dow Corning curing agent (Dow Corning 184B), and mix thoroughly to obtain a PDMS mixture; take 5g of the PDMS mixture and 5g of the micron mixtu...

Embodiment 2

[0041] This embodiment provides a preparation method of porous polydimethylsiloxane with daytime radiation refrigeration, comprising the following steps:

[0042] (1) Synthesis of micron NaCl porogen:

[0043] Add 5ml, 3M NaCl solution (solvent is water) dropwise to 100ml of absolute ethanol under stirring condition, stir for 10min, stop stirring, after standing for 1min, pour off the supernatant, and use a centrifuge to centrifuge , collect the white precipitate; wash the white precipitate with absolute ethanol, centrifuge with a centrifuge to collect the precipitate, put the precipitate in a vacuum drying oven at 100°C for 12 hours and take it out, grind it to powder with agate smoke wave, A micron-sized NaCl porogen with a particle size of 7.5 μm was obtained;

[0044] (2) Weigh 10g of Dow Corning PDMS (Dow Corning 184A) and 2g of Dow Corning curing agent (Dow Corning 184B), and mix thoroughly to obtain a PDMS mixture; take 1g of the PDMS mixture and 6g of the micron mixtu...

Embodiment 3

[0047] This embodiment provides a preparation method of porous polydimethylsiloxane with daytime radiation refrigeration, comprising the following steps:

[0048] (1) Synthesis of micron NaCl porogen:

[0049] Add 5ml, 3M NaCl solution (solvent is water) drop by drop into 100ml absolute ethanol under stirring condition, stir for 10min, stop stirring, after standing for 1min, pour off the supernatant, and use centrifuge to centrifuge, Collect the white precipitate; wash the white precipitate with absolute ethanol, centrifuge it with a centrifuge, collect the precipitate, put the precipitate in a vacuum drying oven at 100°C for 12 hours, take it out, grind it to powder with agate smoke wave, and then A micron-sized NaCl porogen with a particle size of 7.1 μm was obtained;

[0050] (2) Weigh 10g of Dow Corning PDMS (Dow Corning 184A) and 2g of Dow Corning curing agent (Dow Corning 184B), and mix thoroughly to obtain a PDMS mixture; take 2g of the PDMS mixture and 10g of the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com