Cu-TiC electric contact composite material and preparation method thereof

A composite material, electrical contact technology, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of pure copper hardness, low strength, limited application, resistance to arc erosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

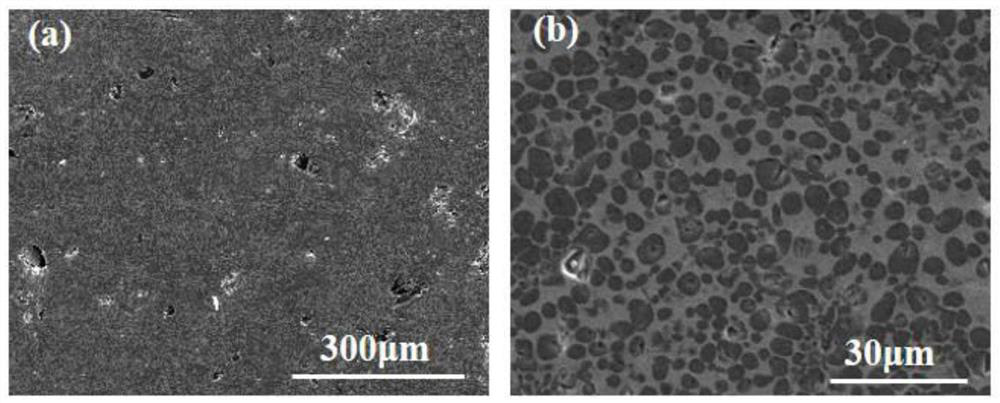

[0030] (1) Raw material preparation: weighed by mass percentage, titanium powder with a particle size of 5 μm and a purity greater than 99%: 24%, graphite powder with a particle size of 50 μm and a purity greater than 99%: 6%, the rest is 50 μm with a purity > 99.5% copper powder;

[0031] (2) Mixing of raw materials: the graphite powder is firstly mixed evenly with part of the copper powder, then fully mixed with the titanium powder and the remaining copper powder to obtain Cu-Ti-graphite mixed powder;

[0032] (3) Cold-press forming: the Cu-Ti-graphite mixed powder obtained in step (2) is cold-pressed into a cylindrical prefabricated block, and the pressure used is 80 MPa.

[0033] (4) Hot-press sintering: place the cold-pressed prefabricated block in a hot-press sintering furnace for hot-press sintering;

[0034] Hot pressing sintering adopts two-step method: first heating to 850°C, holding at 100MPa pressure for 60min, then further raising the temperature to 1050°C, holdi...

Embodiment 2

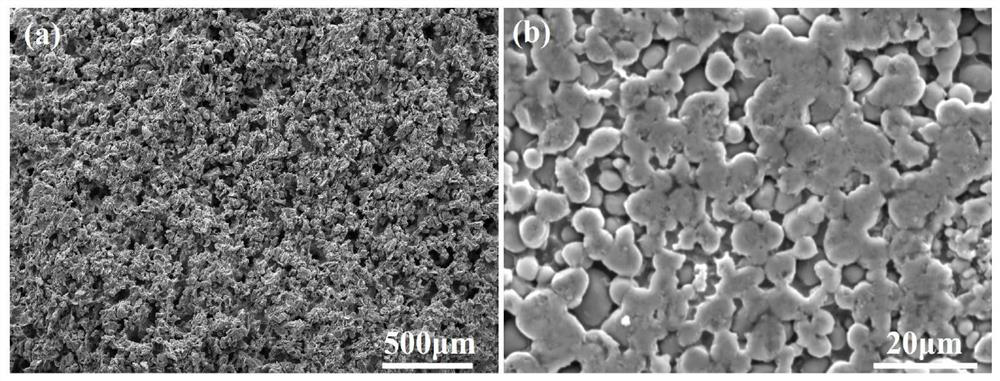

[0038] (1) Raw material preparation: Weigh by mass percentage, titanium powder with a particle size of 50 μm and a purity greater than 99%: 8%, graphite powder with a particle size of 5 μm and a purity greater than 99%: 2%, the rest is 50 μm with a purity > 99.5% copper powder;

[0039] 2) Mixing of raw materials: the graphite powder is firstly mixed evenly with part of the copper powder, and then fully mixed with the titanium powder and the remaining copper powder to obtain Cu-Ti-graphite mixed powder;

[0040] (3) cold press forming: the Cu-Ti-graphite mixed powder obtained in step (2) is cold pressed into a cylindrical prefabricated block, and the pressure used is 80MPa;

[0041] (4) Hot-press sintering: place the cold-pressed prefabricated block in a hot-press sintering furnace for hot-press sintering;

[0042] Hot pressing sintering adopts two-step method: first heating to 850°C, holding at 100MPa pressure for 30min, then further raising the temperature to 1050°C, holdin...

Embodiment 3

[0045] (1) Raw material preparation: Weigh by mass percentage, titanium powder with a particle size of 10 μm and a purity greater than 99%: 4%, graphite powder with a particle size of 3 μm and a purity greater than 99%: 1%, the rest is 20 μm with a purity > 99.5% copper powder;

[0046]2) Mixing of raw materials: the graphite powder is firstly mixed evenly with part of the copper powder, and then fully mixed with the titanium powder and the remaining copper powder to obtain Cu-Ti-graphite mixed powder;

[0047] (3) cold press forming: the Cu-Ti-graphite mixed powder obtained in step (2) is cold pressed into a cylindrical prefabricated block, and the pressure used is 50MPa;

[0048] (4) Hot-press sintering: place the cold-pressed prefabricated block in a hot-press sintering furnace for hot-press sintering;

[0049] Hot pressing sintering adopts two-step method: first heating to 900°C, holding at 100MPa pressure for 30min, then raising the temperature further to 1050°C, holding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com