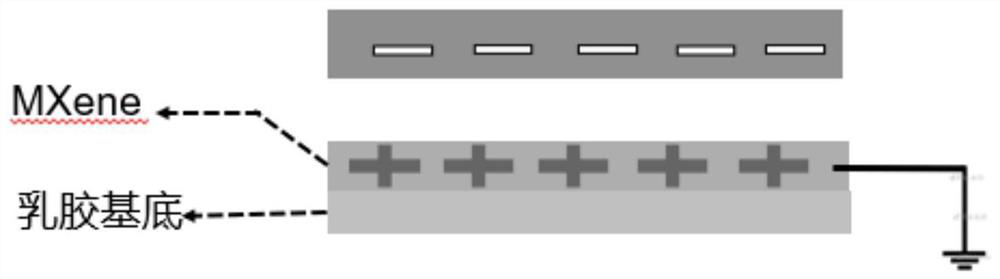

Friction nano-generator based on fold structure MXene film and preparation method of friction nano-generator

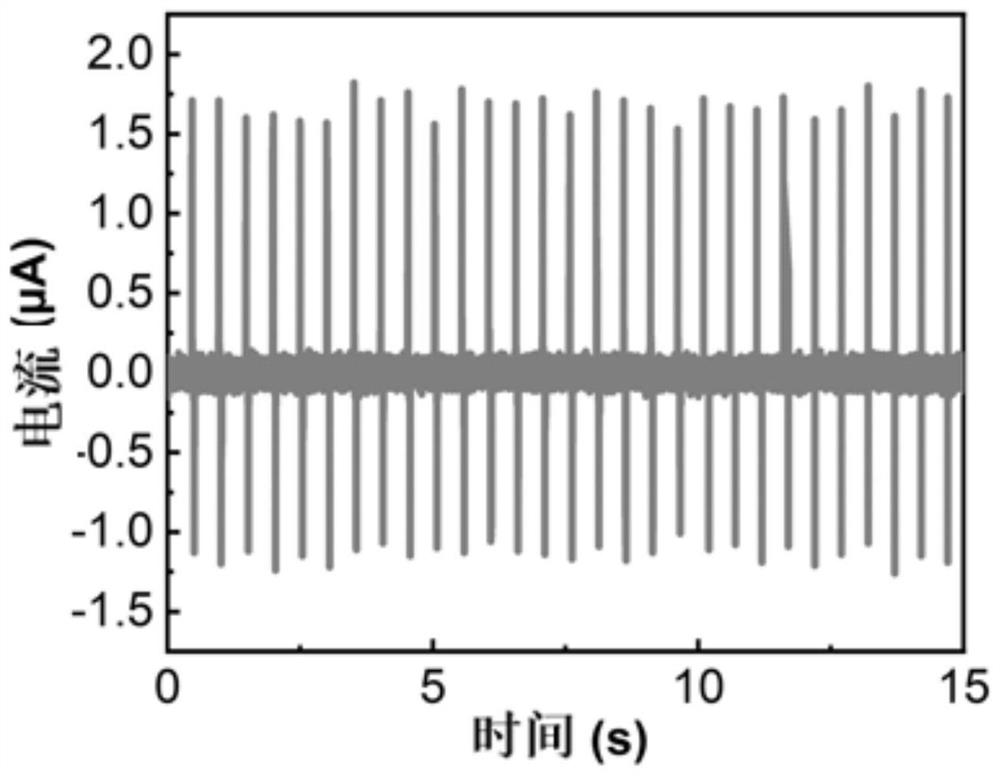

A nano-generator and thin-film technology, which is applied in the direction of triboelectric generators, can solve problems such as insufficient stretching ratio and sensitivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

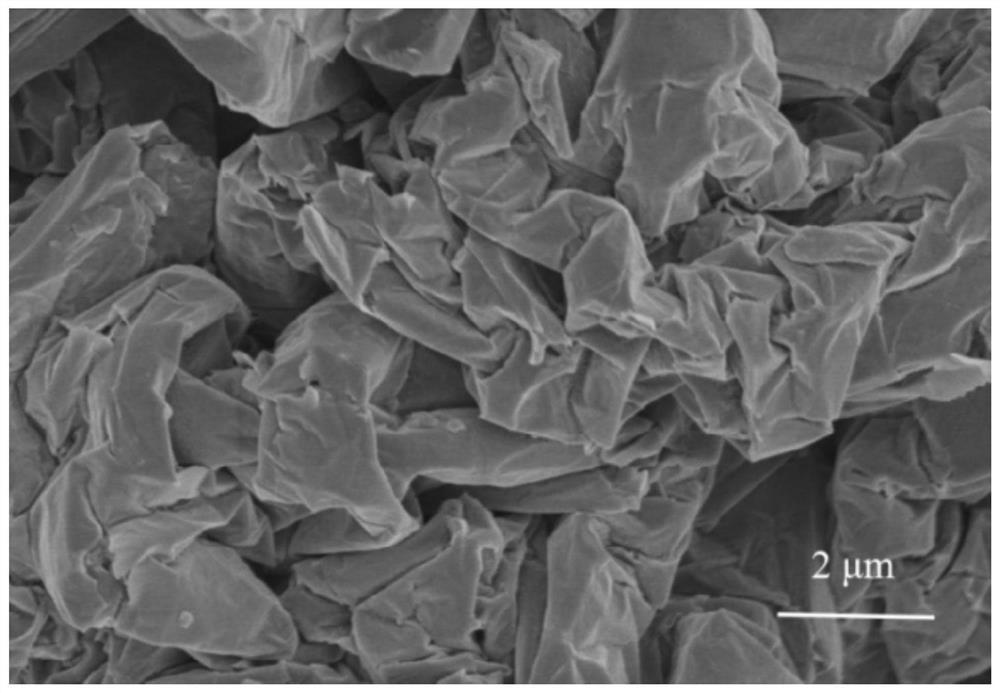

[0042] A method of preparing a friction nano generator, the specific steps are as follows:

[0043] (1) First addition of the Max phase to a mixed solution having a volume ratio of 6: 1 and hydrofluoric acid, stir evenly to obtain a solution X; Max is a mass volume ratio of the maximum mass of the mixed solution; followed by deion Water was used as a dispersion solvent, and the solution was added to the solution X to obtain a solution z; each centrifugal speed was 3500 r / min, each centrifugal time was 3 min, and the amount of deionized water was 50 ml each time; then After adding lithium chloride in solution Z, then 4 times, the centrifugation of 4 times, each centrifugal speed is 3500r / min, each centrifugal time is 3 min; each of the lithium chloride is added to max The mass ratio of the added amount is 1: 1; after the centrifugation is completed, the upper black green solution is a slurry A containing a single layer of MXENE, wherein the concentration of MXENE in the slurry ...

Embodiment 2

[0049] A method of preparing a friction nano generator, the specific steps are as follows:

[0050] (1) First addition of the Max phase to a mixed solution having a volume ratio of 6: 1 and hydrofluoric acid, stir evenly to obtain a solution X; Max is a mass volume ratio of the maximum mass of the mixed solution; followed by deion Water is used as a dispersion solvent, and the solution is carried out twice in solution X to obtain a solution z; each centrifugal speed is 3500 r / min, each centrifugal time is 3 min, each added deionized water volume of 55 mL; then After adding lithium chloride in solution Z, then 4 times, the centrifugation of 4 times, each centrifugal speed is 3500r / min, each centrifugal time is 3 min; each of the lithium chloride is added to max The mass ratio of the added amount is 1: 1; after the centrifugation is completed, the upper black green solution is a slurry A containing a single layer of MXENE, wherein the concentration of the monoland in the slurry ...

Embodiment 3

[0055] A method of preparing a friction nano generator, the specific steps are as follows:

[0056](1) First addition of the Max phase to a mixed solution having a volume ratio of 6: 1 and hydrofluoric acid, stir evenly to obtain a solution X; Max is a mass volume ratio of the maximum mass of the mixed solution; followed by deion The water was used as a dispersion solvent, and the solution was carried out twice in solution x to obtain a solution z; each centrifugal speed was 3500r / min, each centrifugal time was 4 min, and the amount of deionized water was 55ml each time; then After adding lithium chloride in solution Z, then 4 times, the centrifugation of 4 times, each centrifugal speed is 3500r / min, each centrifugal time is 3 min; each of the lithium chloride is added to max The mass ratio of the added amount is 1: 1; after the centrifugation is completed, the upper black green solution is a slurry A containing a single layer of MXENE, wherein the concentration of the monolan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com