Low-temperature disinfectant as well as preparation method thereof, manufacturing assembly and disinfection equipment

A disinfectant, low temperature technology, applied in the field of low temperature disinfectant and its preparation, can solve the problems of increased resource consumption, reduced disinfection effect of disinfectant, toxicity and the like, and achieves the effects of low price and good sterilization and disinfection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

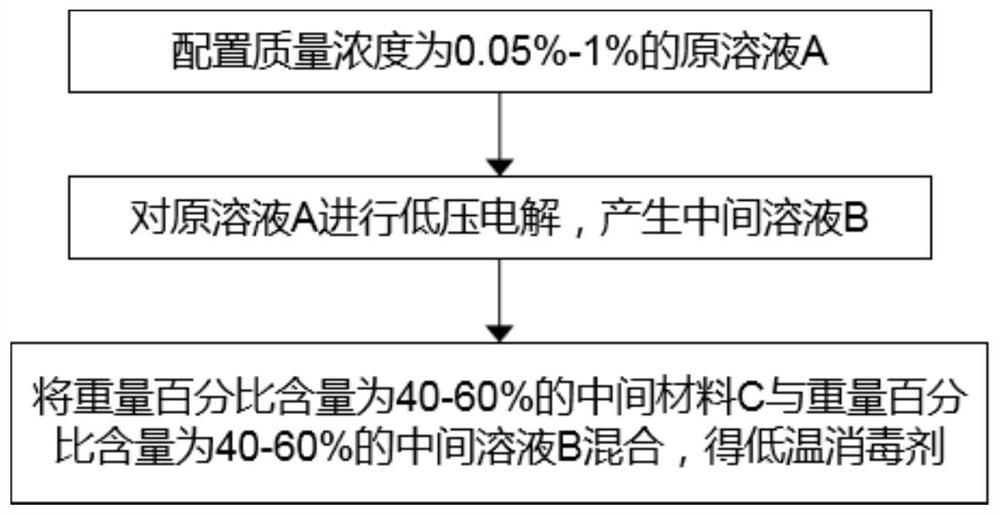

[0024] In order to solve the technical problem, the present invention provides a low-temperature disinfectant, which has strong antifreeze ability, can not freeze at -20°C and has a good sterilization and disinfection effect. The preparation method of the low-temperature disinfectant is provided below, Including the following steps:

[0025] Step S1: Prepare the original solution A with a mass concentration of 0.05%-1%.

[0026] Step S2: Perform low-pressure electrolysis on the original solution A to produce an intermediate solution B.

[0027] Step S3: Mix the intermediate material C with a content of 40-60% by weight and the intermediate solution B with a content of 40-60% by weight to obtain a low-temperature disinfectant.

[0028] Wherein, the original solution A includes one or more of hydrochloride or sulfate, and the intermediate material C is an alcoholic organic compound.

[0029] The low-temperature disinfectant provided by the present invention is prepared by the ...

Embodiment 1

[0056] Step S1: Prepare a sodium chloride solution with a mass concentration of 0.05%-1%.

[0057] Step S2: put the sodium chloride solution into the electrolytic cell for 5 minutes and circulate the electrolysis to obtain the disinfection material. The current of the electrolytic cell is about 3A, and the voltage is about 14V. The electrolytic cell is a PEM electrolytic cell, the anode is conductive diamond, and the cathode is stainless steel.

[0058] Step S3: Mix the disinfection material and the low-temperature material at a ratio of 4:6 to obtain a low-temperature disinfectant. The low-temperature material is a mixture of ethylene glycol and ethanol at a ratio of 8:2.

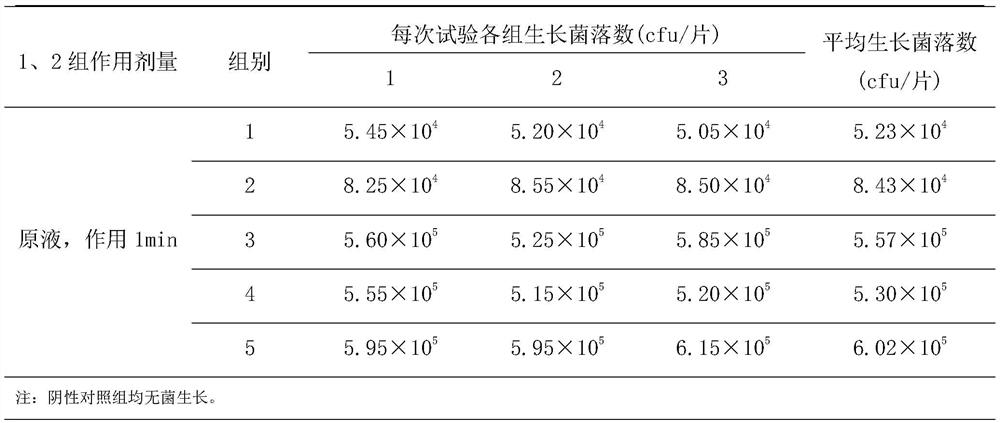

[0059] The low-temperature disinfectant obtained in this example can be refrigerated at -20°C for more than 12 hours without freezing, and can directly act on the surface of objects or perform disinfection operations by spraying or other methods. Use the low-temperature disinfectant of the present embodi...

Embodiment 2

[0061] Step S1: Prepare a sodium chloride solution with a mass concentration of 0.05%-1%.

[0062] Step S2: put the sodium chloride solution into the electrolytic cell for 8 minutes and circulate the electrolysis to obtain the disinfection material. The current of the electrolytic cell is about 3A, and the voltage is about 14V. The electrolytic cell is a PEM electrolytic cell, the anode is conductive diamond, and the cathode is stainless steel.

[0063] Step S3: Mix the disinfection material and the low-temperature material at a ratio of 4:6 to obtain a low-temperature disinfectant. The low-temperature material is a mixture of ethylene glycol and ethanol at a ratio of 8:2.

[0064] The low-temperature disinfectant obtained in this example can be refrigerated at -20°C for more than 12 hours without freezing, and can directly act on the surface of objects or perform disinfection operations by spraying or other methods. Use the low-temperature disinfectant of the present embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com