Wastewater electro-oxidation treatment method based on current density cascade control

A technology of current density and treatment method, applied in the field of wastewater electro-oxidation treatment based on current density cascade control, can solve problems such as high energy consumption and limit large-scale industrial applications, and achieves improved mass transfer reaction, is conducive to degradation, and improves current The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

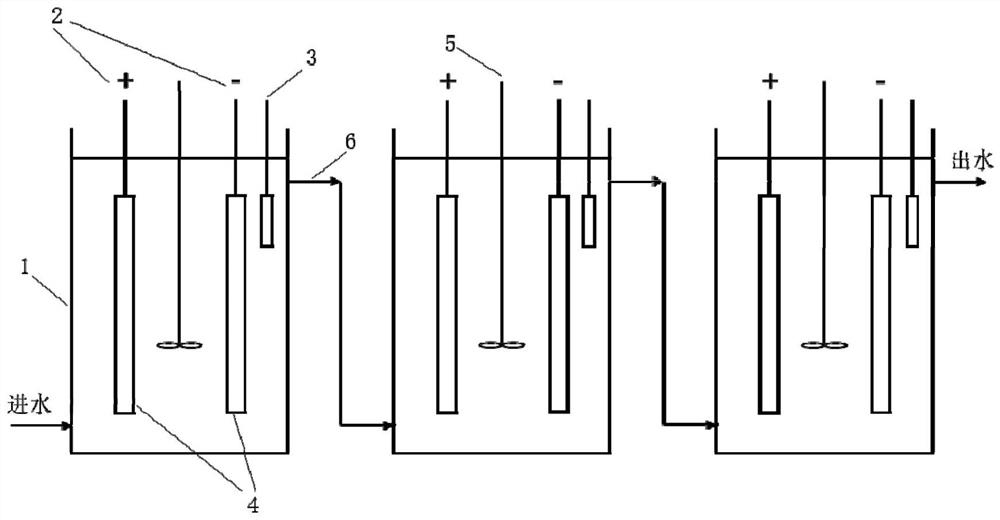

[0018] Such as figure 1 As shown, the wastewater electrooxidation treatment method based on current density step control of the present invention adopts a continuous stirring box type electrooxidation device, including a DC power controller 2, a pollutant monitor 3, an electrode assembly 4 and a reaction unit 1. Stirrer 5. The pollutant monitor 3 monitors the concentration of pollutants in each reaction unit of the electro-oxidation device, and feeds it back to the DC power controller 2, and the DC power controller 2 performs cascade control of the current density.

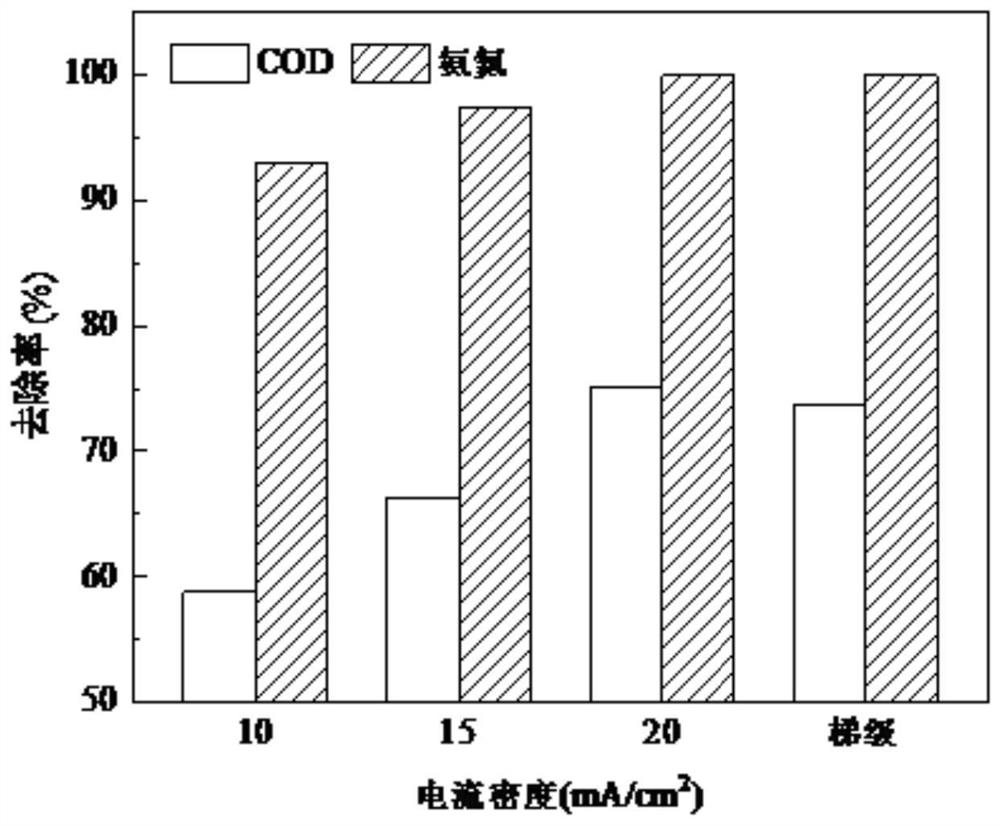

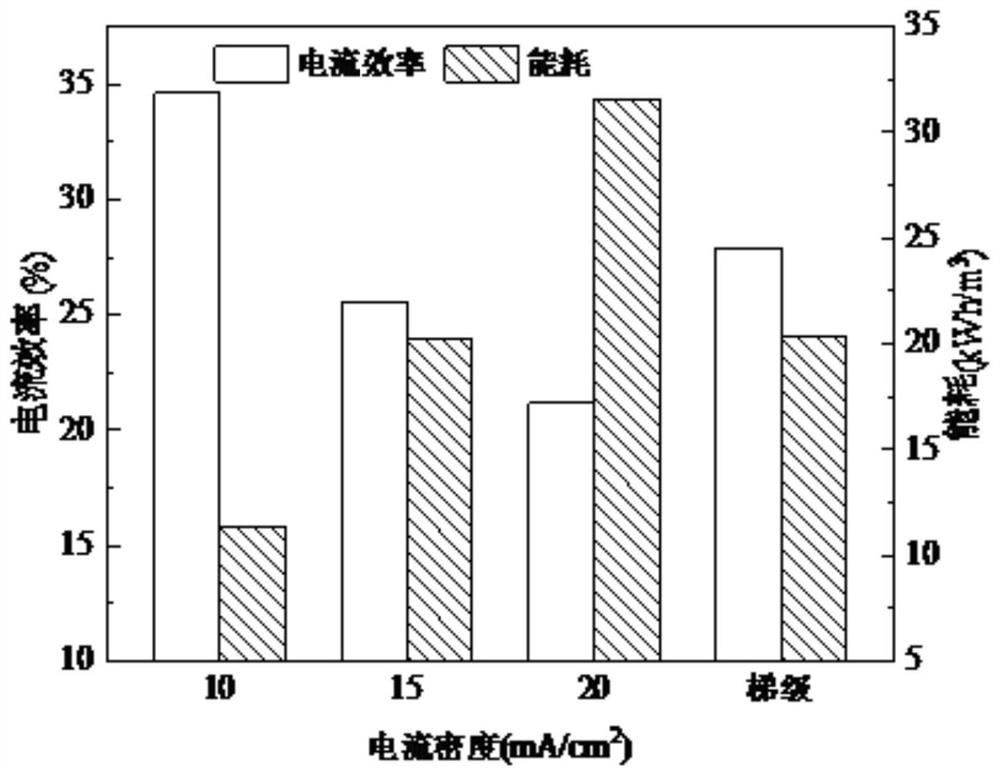

[0019] This method is used to treat the actual wastewater of a textile printing and dyeing enterprise. The average concentration of COD in wastewater is 285mg / L, the average concentration of ammonia nitrogen is 35mg-N / L, and pH 9. Three reaction units are designed, and the hydraulic retention time of each reaction unit is 60min. The electrode spacing is 1cm, and the current density range is 10-20mA / cm 2 , stepwi...

Embodiment 2

[0021] This method is used to treat the actual wastewater of a pharmaceutical company. The average concentration of COD in the wastewater is 895mg / L, the average concentration of ammonia nitrogen is 155mg-N / L, and the pH is 8.6. Two reaction units are designed, and the hydraulic retention time of each reaction unit is 90min. The spacing is 4cm, the current density range is 27.5~30mA / cm 2 , stepwise decrease of 2.5mA / cm in front and back reaction units 2 , that is, the first reaction unit sets the current density to 30mA / cm 2 , the second reaction unit set the current density 27.5mA / cm 2 . After treatment, the removal rates of COD and ammonia nitrogen are 67.2% and 92.1%, respectively, the current efficiency is 37.2%, and the energy consumption is 33.4kWh / m 3 . Compared with the traditional electro-oxidation process (30mA / cm 2 ), the pollutant removal rate is very close, but the energy saving is about 21.2%.

Embodiment 3

[0023] This method is used to treat actual wastewater in an industrial park. The average concentration of COD in wastewater is 220mg / L, the average concentration of ammonia nitrogen is 25mg-N / L, and pH 6. Four reaction units are designed, and the hydraulic retention time of each reaction unit is 20min. The distance is 1cm, the current density range is 5~12.5mA / cm 2 , stepwise decrease of 2.5mA / cm in front and back reaction units 2 , that is, the first reaction unit sets the current density to 12.5mA / cm 2 , the second reaction unit set the current density 10mA / cm 2 , the third reaction unit set the current density 7.5mA / cm 2 , the fourth reaction unit set the current density 5mA / cm 2 . After treatment, the removal rates of COD and ammonia nitrogen are 90% and 100% respectively, the current efficiency is 33.6%, and the energy consumption is 13.6kWh / m 3 . Compared with the traditional electro-oxidation process (12.5mA / cm 2 ), the pollutant removal rate is very close, but t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com