Modified bamboo fiber-suspended magnetic filler and preparation method thereof

A magnetic filler and bamboo fiber technology, applied in the direction of chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problem of lack of hydrophilicity, biocompatibility and mechanical strength, and does not provide magnetic suspension Filler preparation methods and other issues, to achieve high bio-affinity, high efficiency, easy to hang film effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

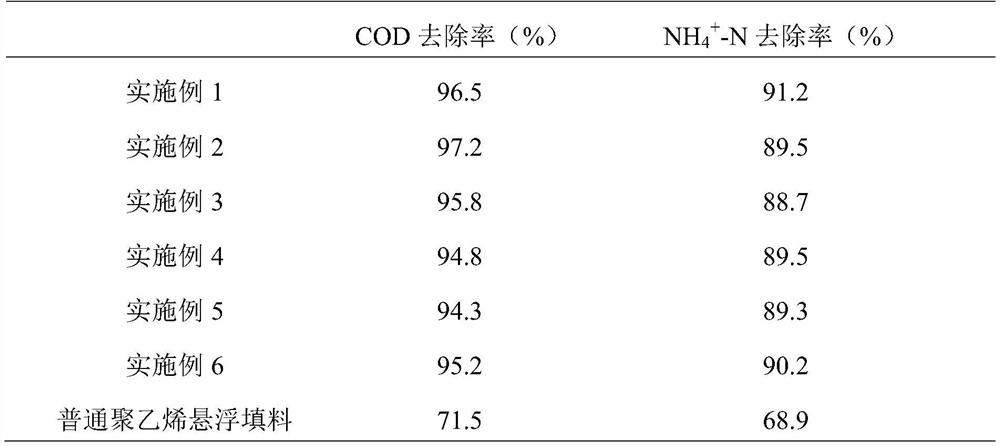

Embodiment 1

[0028] A kind of modified bamboo fiber suspended magnetic filler and preparation method thereof

[0029] The modified bamboo fiber suspended magnetic filler is formed by blending, extruding and cutting magnetized polyethylene and modified bamboo fiber; the weight ratio of the magnetized polyethylene to the modified bamboo fiber is 1:0.2; the magnetized polyethylene is modified It is blended with polyethylene and magnetic active powder; the above magnetic active powder is Si-Fe 3 o 4 / PEI-EDTA magnetic nano powder; the weight ratio of the above-mentioned modified polyethylene to the magnetizing active powder is 1:0.01; the above-mentioned modified bamboo fiber is surface-modified thick bamboo fiber.

[0030] In the present embodiment, the above-mentioned modified polyethylene includes the following raw materials in parts by weight: 80kg of high-density polyethylene, 5kg of rare earth compound, 2kg of hydrophilic polymer, 1kg of calcium hardate, 15kg of montmorillonite powder, ...

Embodiment 2

[0038] A kind of modified bamboo fiber suspended magnetic filler and preparation method thereof

[0039] The modified bamboo fiber suspended magnetic filler is formed by blending, extruding and cutting magnetized polyethylene and modified bamboo fiber; the weight ratio of the magnetized polyethylene to the modified bamboo fiber is 1:0.25; the magnetized polyethylene is modified It is blended with polyethylene and magnetic active powder; the above magnetic active powder is Si-Fe 3 o 4 / PEI-EDTA magnetic nano powder; the weight ratio of the above-mentioned modified polyethylene to the magnetizing active powder is 1:0.15; the above-mentioned modified bamboo fiber is a surface-modified thick bamboo fiber.

[0040] In the present embodiment, the above-mentioned modified polyethylene includes the following raw materials in parts by weight: 85kg of high-density polyethylene, 7kg of rare earth compound, 2.5kg of hydrophilic polymer, 1.5kg of calcium hardate, 18kg of montmorillonite p...

Embodiment 3

[0048] A kind of modified bamboo fiber suspended magnetic filler and preparation method thereof

[0049] The modified bamboo fiber suspended magnetic filler is formed by blending, extruding and cutting magnetized polyethylene and modified bamboo fiber; the weight ratio of the magnetized polyethylene to the modified bamboo fiber is 1:0.3; the magnetized polyethylene is modified It is blended with polyethylene and magnetic active powder; the above magnetic active powder is Si-Fe 3 o 4 / PEI-EDTA magnetic nano powder; the weight ratio of the above-mentioned modified polyethylene to the magnetizing active powder is 1:0.015; the above-mentioned modified bamboo fiber is a surface-modified thick bamboo fiber.

[0050] In the present embodiment, the above-mentioned modified polyethylene includes the following raw materials in parts by weight: 88kg of high-density polyethylene, 9kg of rare earth compound, 3.5kg of hydrophilic polymer, 1.5kg of calcium hardate, 20kg of montmorillonite p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com