Production process of chloropinacolone

A production process, pinatonone technology, applied in the field of monochloropinatone production process, can solve the problems of long reaction time, low production yield, high viscosity, etc., reduce production equipment and production consumption, and reduce production raw material consumption , The effect of reducing the chlorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

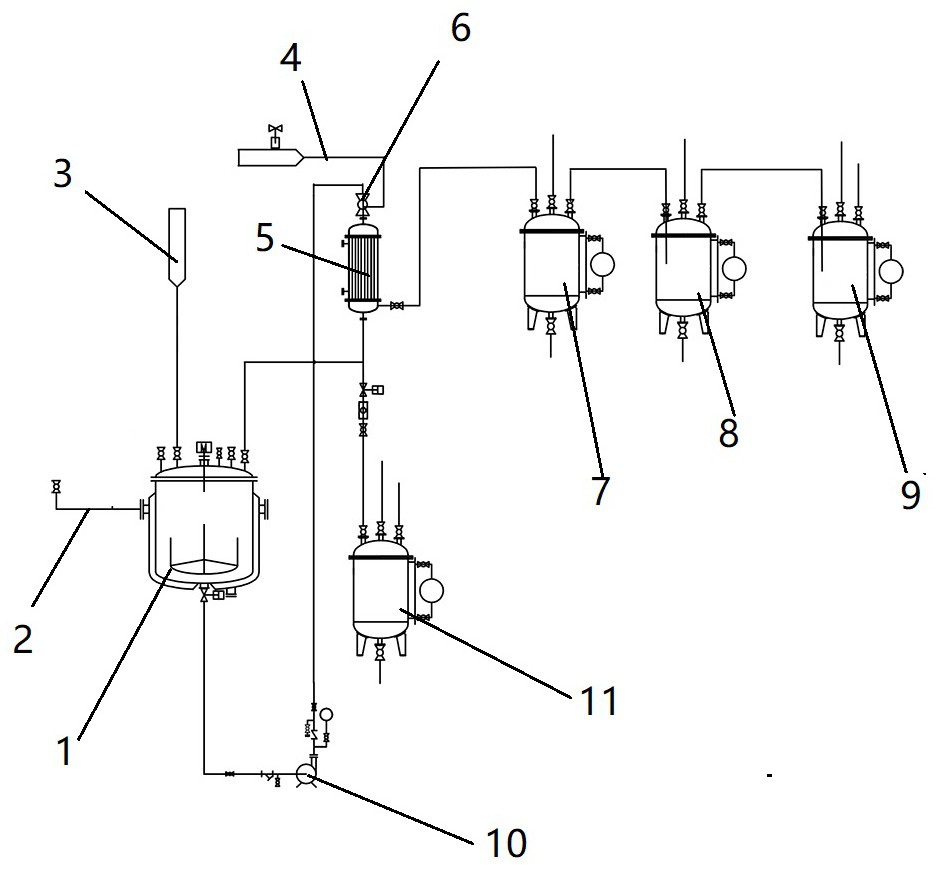

[0010] Embodiment: drop into 100kg pinacolone and 200kg methyl alcohol in the mixing kettle 3, after mixing evenly, pinacolone-methanol is dropped in the reactor 1, the stirring of opening reactor and the brine cooling pipeline 2, in the reactor The temperature of the pinacolone-methanol mother liquor drops below 0°C; the circulating pump 10 is turned on, and the pinacolone-methanol solution is repeatedly circulated from the reactor circulation outlet to the feed inlet, and a cooling heat exchanger 5 is arranged on the circulation pipeline. Keep the temperature of the circulating mother liquid below 0°C, install a Venturi mixer 6 at the inlet of the cooling heat exchanger, connect the gas inlet of the Venturi mixer to the chlorine gas pipeline 4, and add chlorine gas at a rate of 0.5-1.0kg / min, repeat the cycle After the addition of chlorine gas, keep it for 30 minutes. After the reaction is completed, stop the circulation, open the inlet valve of the precipitation kettle, pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com