Multicolor low-gloss water-based acrylic polyurethane finish paint for passenger train and preparation method of multicolor low-gloss water-based acrylic polyurethane finish paint

A technology of acrylic polyurethane and water-based acrylic, which is applied in the direction of polyurea/polyurethane coatings, multi-color effect coatings, coatings, etc. It can solve the problems of poor gloss stability of the paint film, reduce the gloss of the topcoat, and have no cost advantage. The effect of reducing the content of volatile organic compounds, stabilizing the gloss of the paint film, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides the preparation method of above-mentioned multi-color low-gloss water-based acrylic polyurethane topcoat for railway passenger cars, comprising the following steps:

[0033] The first step is to prepare component A: weigh each component according to the formula amount, first mix 4 / 5 of deionized water, 1 / 5 of hydroxyl-containing water-based acrylic resin, 1 / 2 of defoamer, dispersant, Wetting agent is added under stirring at 300-400r / min, after adding, stir for 10-15min to mix evenly, slowly add rheological additive, increase the speed to 600-800r / min and stir for 15-20min, then add various pigments , 800-1000r / min high-speed dispersion and stirring for 20-30min to obtain a pre-dispersed slurry; the upper sand mill grinds the pre-dispersed slurry to a fineness of less than 15 μm to obtain a finely ground slurry; grind the finely ground slurry at 600-800r / min Add 4 / 5 of hydroxyl-containing water-based acrylic resin, self-dulling water-based polyuret...

Embodiment 1--4

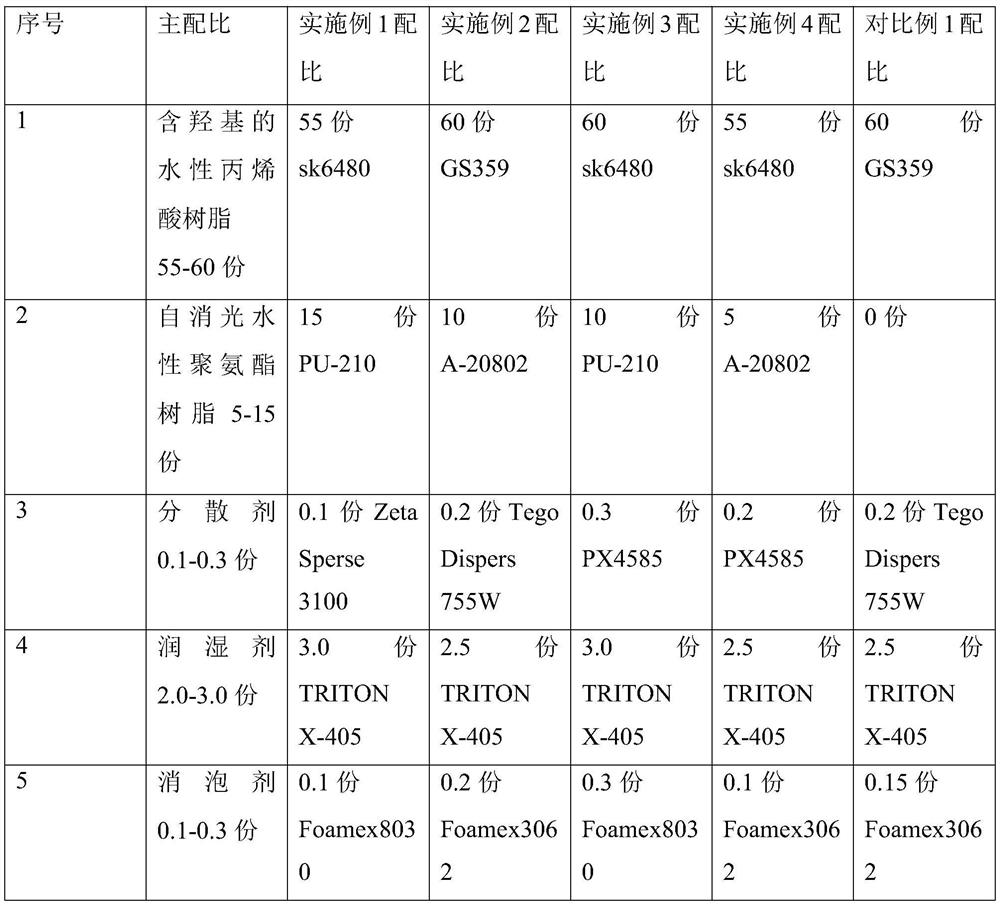

[0037] Embodiment 1-4 takes the raw material according to the proportioning amount in the following table 1, according to the processing parameters of the preparation method in the real table 2 and the preparation method to process the multi-color low gloss water-based acrylic polyurethane topcoat product for railway passenger cars, specifically see table 1 and Table 2.

[0038] Table 1: Raw material ratio table of embodiment 1-4

[0039]

[0040]

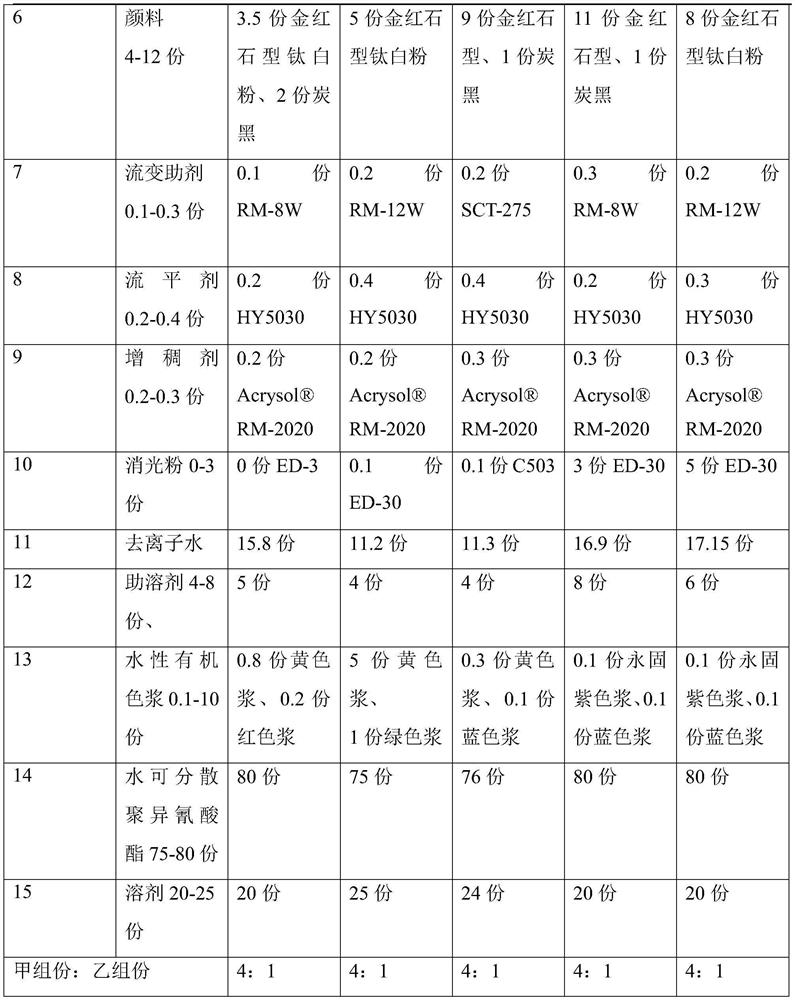

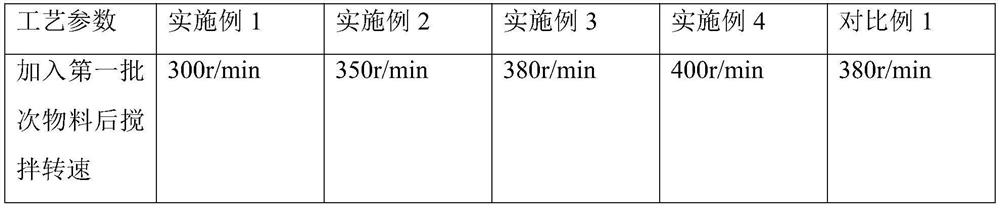

[0041] Table 2: Embodiment 1-4 process parameter table

[0042]

[0043]

[0044] The process parameters involved in Table 2 respectively correspond to the process parameters involved in the first step of the preparation process in sequence. Among them, "adding the first batch of materials" and "adding the second batch of materials" respectively correspond to the process of adding multiple raw materials in the first step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com