Reactive polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, reactive technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of low initial adhesion of hot-melt adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

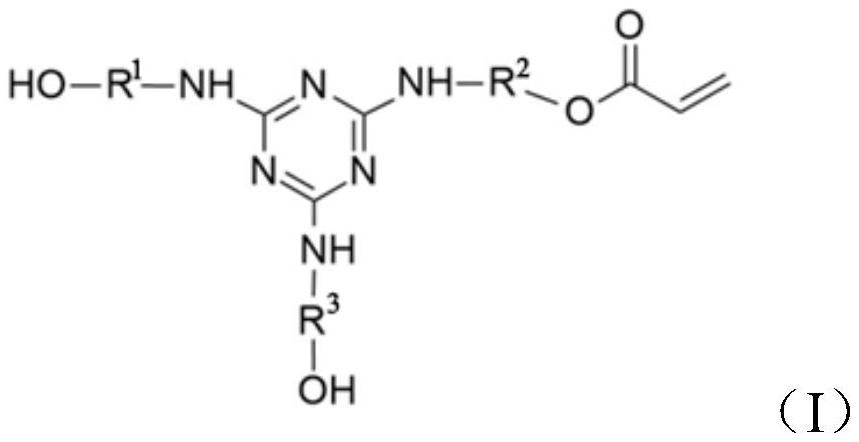

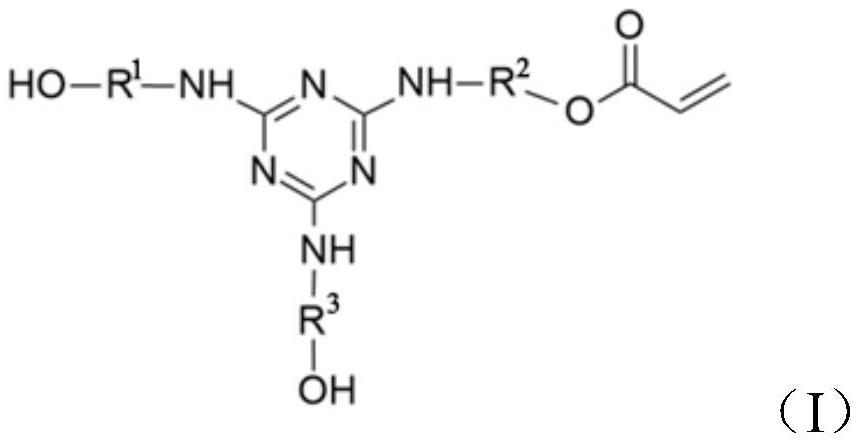

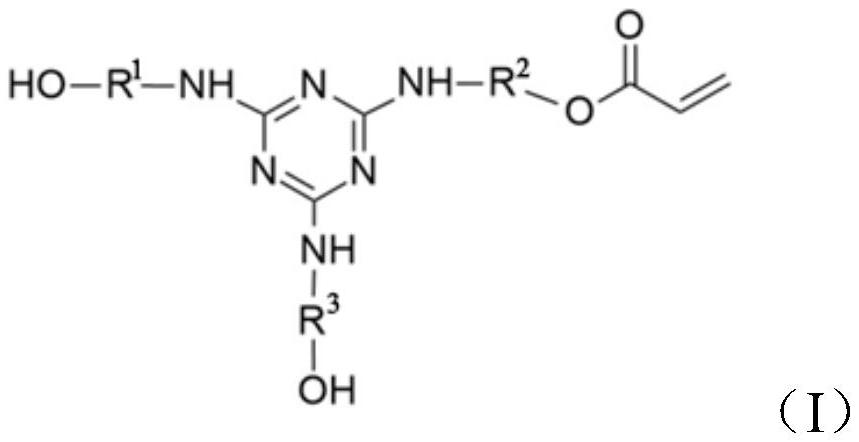

[0060] In the present embodiment, the molecular weight is 42 parts of crystalline polyester polyols of 3500, the molecular weight is 29 parts of amorphous polyester polyols of 3500, and the molecular weight is 29 parts of polyoxypropylene diols of 2000, shown in formula (I) 10 parts of the compound, wherein R is CH 2 CH 2 Alkyl, 29 parts of 4,4'-diphenylmethane diisocyanate, 20 parts of thermoplastic acrylic resin, photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propanone, and 2,4,6 - 0.5 parts of trimethylbenzoyl-diphenylphosphine oxide and methyl benzoylformate, antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] A total of 0.32 parts of pentaerythritol ester and β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 1.5 parts of silane coupling agent γ-glycidyl etheroxypropyl trimethoxysilane .

[0061] Stir and mix polymer polyols, compounds containing acrylate-based diols, and antioxidants, heat up to 120°C, and dehydrate for 0.5 hours under a v...

Embodiment 2

[0063] In this example, its specific implementation is similar to Example 1, except that: 50 parts of crystalline polyester polyols with a molecular weight of 3500, 25 parts of amorphous polyester polyols with a molecular weight of 3500, and a molecular weight of 2000 25 parts of polyoxypropylene diols, 9 parts of compounds shown in formula (I), wherein R is CH 2 CH 2 Alkyl, 28 parts of 4,4'-diphenylmethane diisocyanate, 19 parts of thermoplastic acrylic resin, photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propanone and 1-hydroxycyclohexylbenzene A total of 0.65 parts of methyl ketone, 0.46 parts of antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, silane coupling agent γ-glycidyl ether oxypropyl 1.4 parts of trimethoxysilane.

Embodiment 3

[0065] In this example, its specific implementation is similar to that of Example 1, except that: 48 parts of crystalline polyester polyols with a molecular weight of 3500, 24 parts of amorphous polyester polyols with a molecular weight of 3500, and a molecular weight of 2000 28 parts of polyoxypropylene diols, 12 parts of compounds shown in formula (I), wherein R is CH 2 CH 2 CH 2 Alkyl, 31 parts of 4,4'-diphenylmethane diisocyanate, 25 parts of terpene resin, photoinitiator 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone and 2, A total of 0.55 parts of 4,6-trimethylbenzoyl-diphenylphosphine oxide, antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and β - 0.3 parts of octadecyl (3,5-di-tert-butyl-4-hydroxyphenyl) propionate in total, and 1.5 parts of silane coupling agent γ-methylpropionyloxypropyl trimethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com