High-corrosion-resistance workpiece surface treating agent and preparation method thereof

A workpiece surface, corrosion-resistant technology, applied in the direction of metal material coating process, etc., can solve the problems of slow drying speed, influence of workpiece surface, residual water marks on workpiece surface during drying time, etc., to avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A high corrosion-resistant workpiece surface treatment agent consists of 10 parts of the following weight: 10 parts of potassium pyrophosphate, 1 tin sulfate, 2 sulfate, 1 sulfate, 1 quick dry agent; quick dry agent by the following A weight of the weight of the weight: 10 nano-titanium dioxide, 1 carbonous ash, 10 potassium permanganate solution.

[0045] The surface treatment agent prepared by the present embodiment was sprayed with the workpiece, and after the spray was completed, it was allowed to stand for 2 h. After standing, the workpiece was placed in the position of the air in 1 day, and after 1 day, after 1 day, workpiece The surface of the surface is measured.

Embodiment 2

[0047] A high corrosion workpiece surface treatment agent consists of 1 weight of the following weight: 13 parts of potassium pyrophosphate, 2 copies of sulfate, 3 sulfate, 2 sulfate, 2 quick-drying agents; quick-drying agent by the following The weight of the weight of the weight: 13 parts of nano-titanium dioxide, 3 serum ash, and 13 potassium permanganate solutions.

[0048] The surface treatment agent prepared by the present embodiment was sprayed with the workpiece, and after the spray was completed, it was allowed to stand for 2 h. After standing, the workpiece was placed in the position of the air in 1 day, and after 1 day, after 1 day, workpiece The surface of the surface is measured.

Embodiment 3

[0050] A high corrosion-resistant workpiece surface treatment agent consists of 15 raw materials of the following weight: 5 potassium pyrophosphate, 3 copies of sulfate, 5 sulfate, 3 sulfate, 3 quick-drying agents; quick-drying agent by the following A weight of the weight of the weight: 15 parts of nano-titanium dioxide, 5 serum ash, 15 potassium permanganate solutions.

[0051] The surface treatment agent prepared by the present embodiment was sprayed with the workpiece, and after the spray was completed, it was allowed to stand for 2 h. After standing, the workpiece was placed in the position of the air in 1 day, and after 1 day, after 1 day, workpiece The surface of the surface is measured.

[0052] As can be seen from Examples 1-3, the surface treatment agent of the present invention can be quickly dried, and the surface treatment agent of the high corrosion workpiece is not easily left after spraying in the workpiece. .

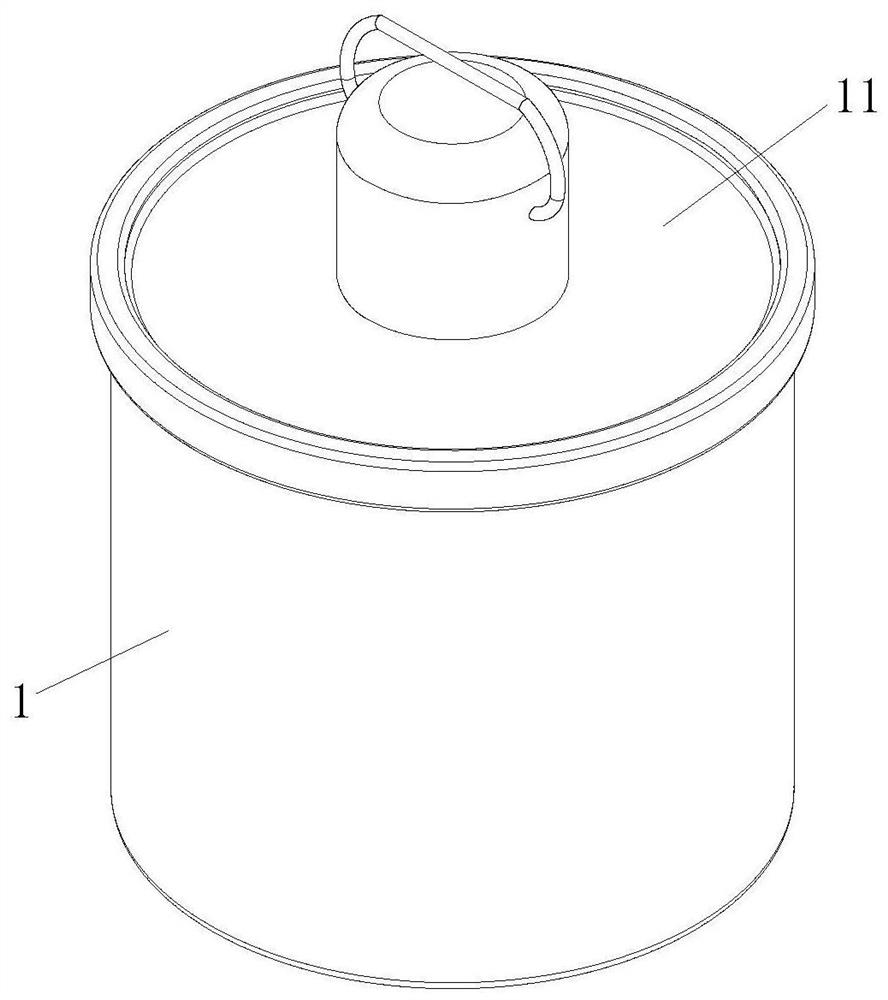

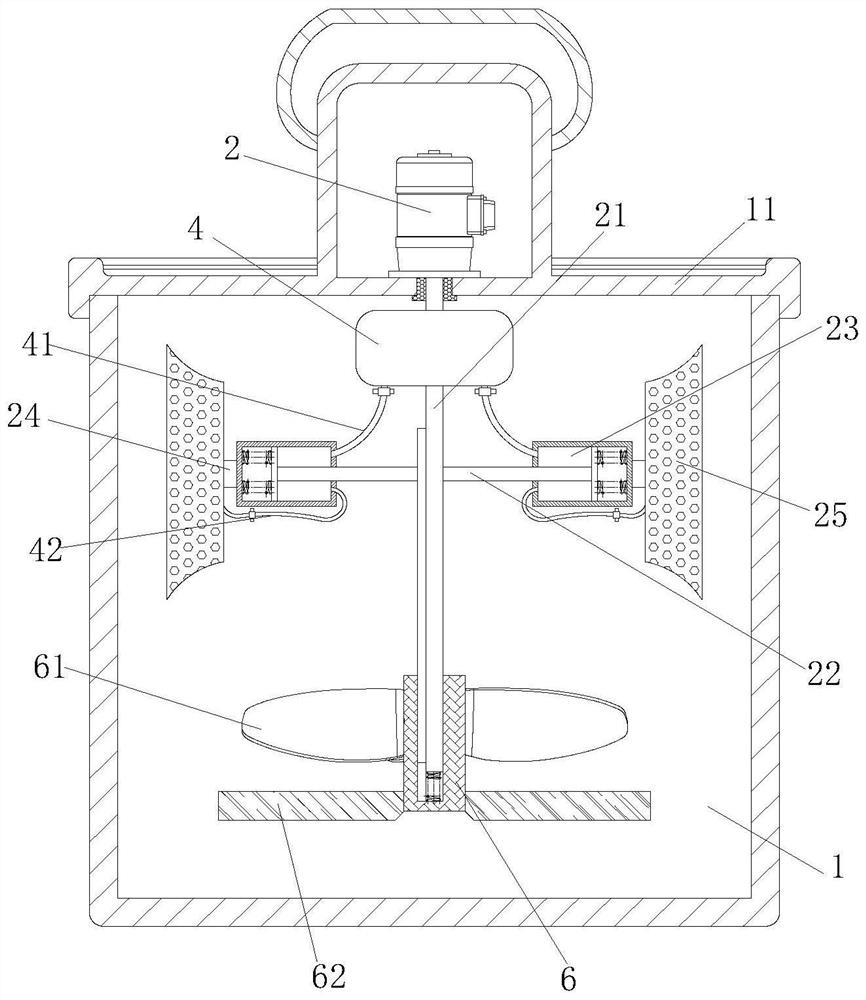

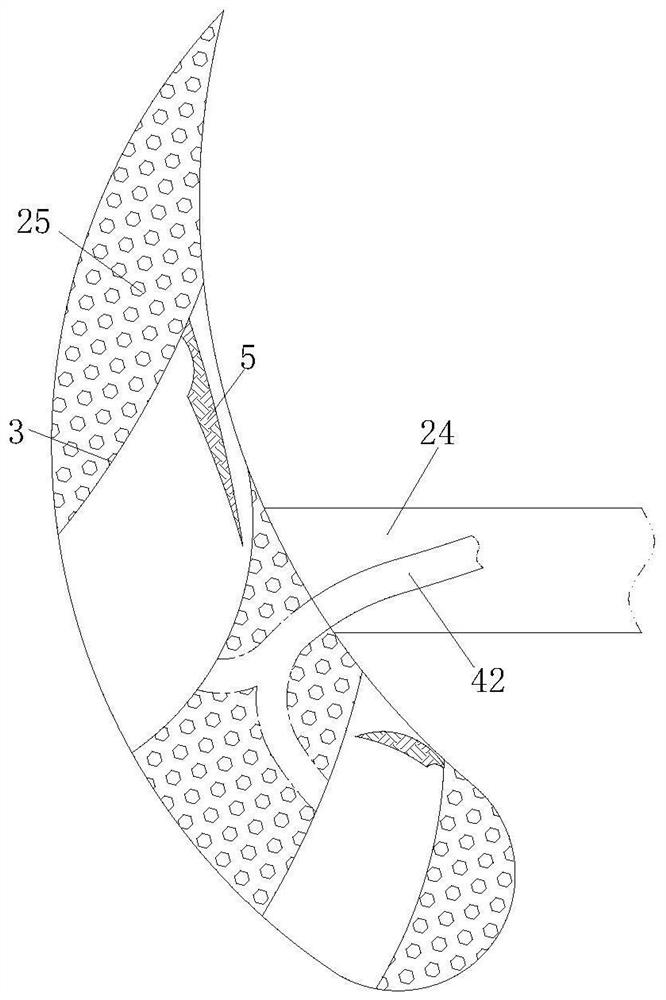

[0053] Such as Figure 1 - Figure 7 As shown, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com