Rare earth magnesium alloy metallographic corrosive and application thereof

A technology of rare earth magnesium and corrosive agent, which is applied in the preparation of test samples, etc., can solve the problems of complicated operation and increased input cost, and achieve the effect of simple operation, clear organization and low condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

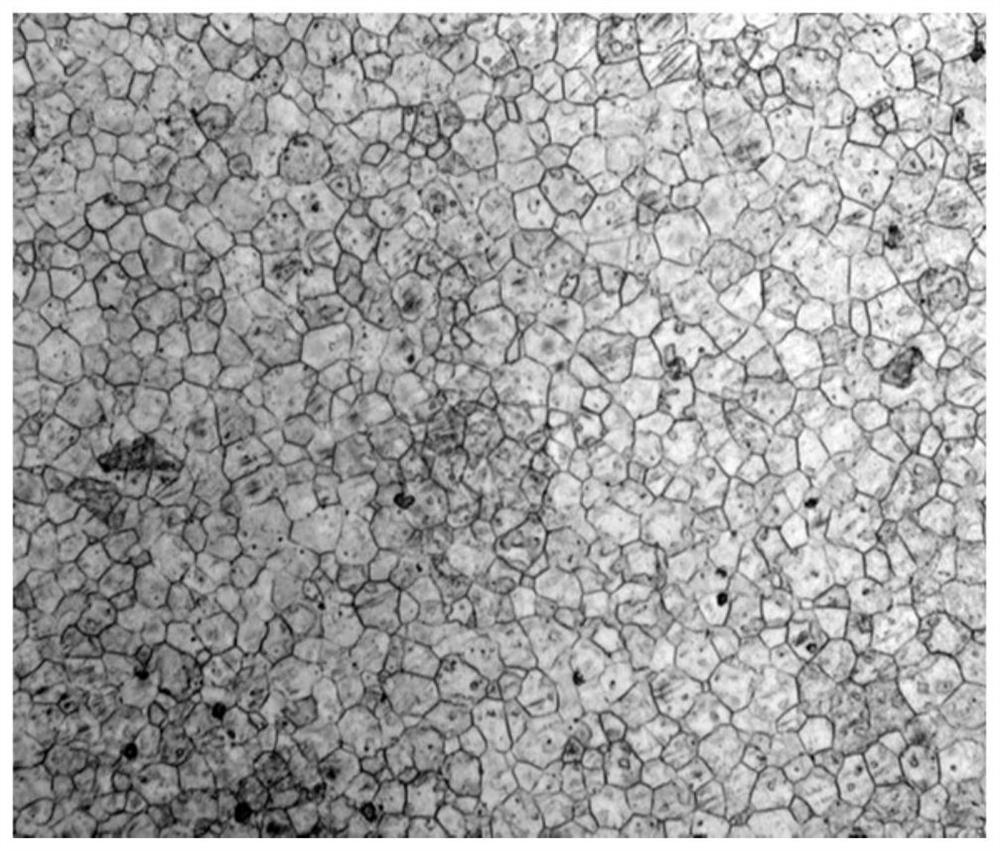

Image

Examples

Embodiment 1

[0029] The rare earth magnesium alloy metallographic etchant of this embodiment consists of the following components: 2.5g of sodium chloride, 11g of boric acid, 24ml of glycerin, 50ml of absolute ethanol, and 26ml of distilled water.

[0030] The content of rare earth in rare earth magnesium alloy is 7%.

Embodiment 2

[0032] The rare earth magnesium alloy metallographic etchant of this embodiment is composed of the following components: 3.5g potassium chloride, 9g boric acid, 20ml glycerin, 60ml absolute ethanol, and 20ml distilled water.

[0033] The rare earth content in the rare earth magnesium alloy is 10%.

Embodiment 3

[0035] The rare earth magnesium alloy metallographic etchant of this embodiment is composed of the following components: 4.5g sodium chloride, 7g boric acid, 16ml glycerin, 70ml absolute ethanol, and 14ml distilled water.

[0036] The rare earth content in rare earth magnesium alloy is selected as 13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com