Fabricated leveling composite radiation energy-saving concrete wall and construction method thereof

A technology of concrete wall and composite radiation, applied in the field of building walls, can solve the problems of wall damage, difficult installation, high density, etc., and achieve the effect of reducing thickness and self-weight, fast and installation, and quiet installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

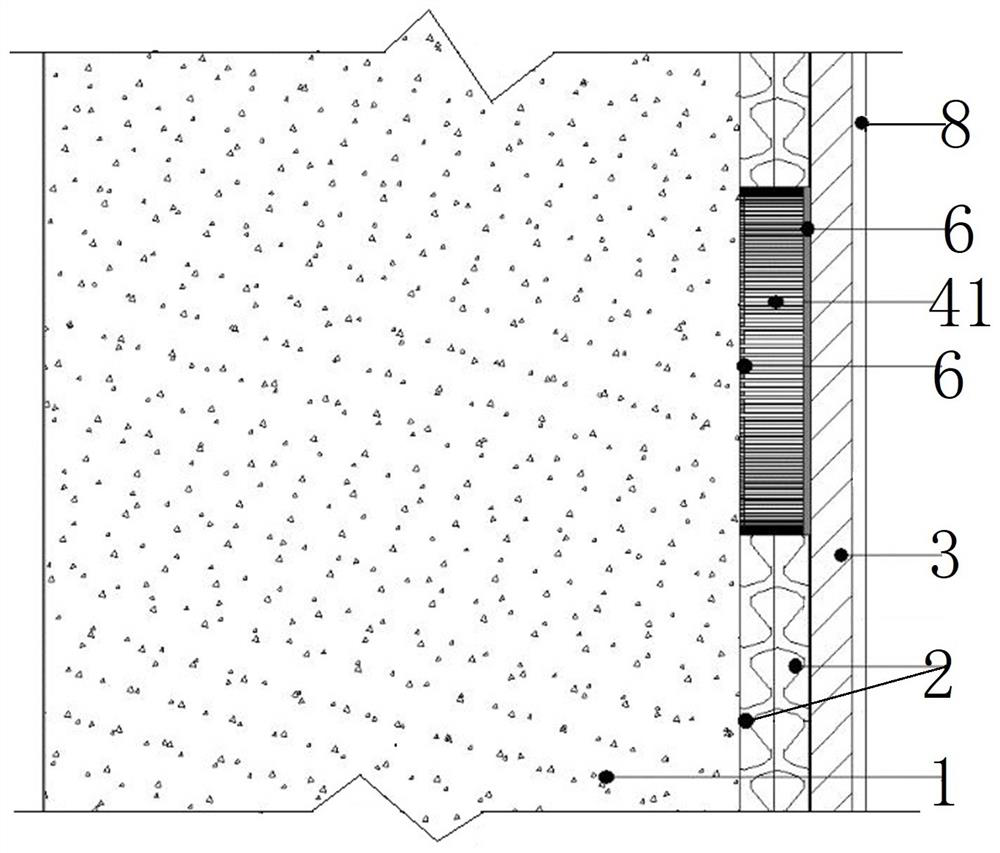

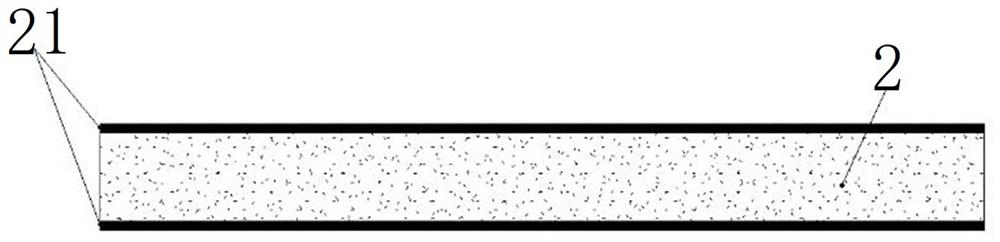

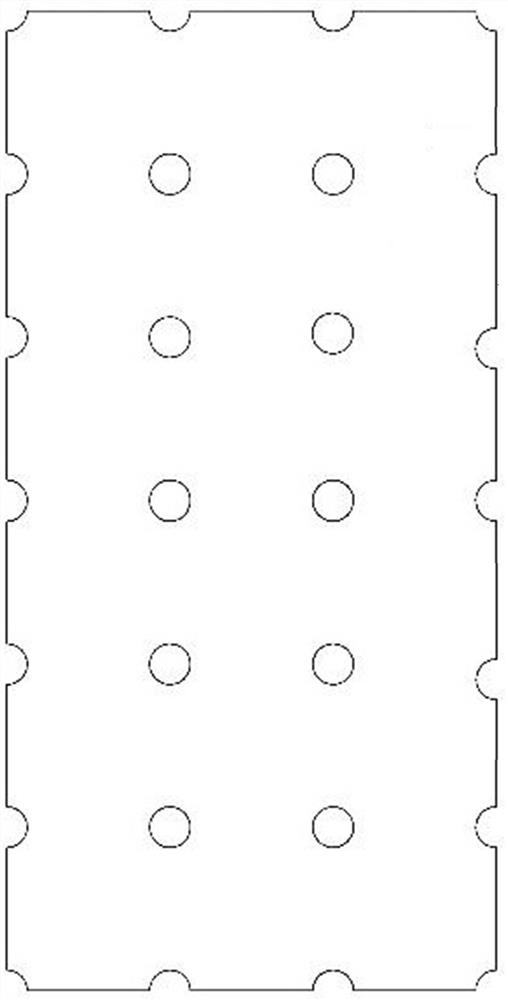

[0047] Such as figure 1 As shown, the prefabricated leveling composite radiant energy-saving concrete wall includes a concrete wall 1; it also includes a thermal insulation coil 2 wrapped on the surface of the concrete wall 1, and a decorative panel arranged on the outer surface of the thermal insulation coil 2. The panel 3, the supporting member for preventing the thermal insulation coiled material 2 from being crushed is evenly arranged between the decorative panel 3 and the surface of the concrete wall 1 . Here the thermal insulation system can be arranged on one side or both sides of the concrete wall 1 . Here the veneer 3 also plays a protective role, separating the thermal insulation coil 2 from the outside world.

[0048] The veneer 3 is connected to the surface of the concrete wall 1 through a support, and the dimension of the support in the direction perpendicular to the veneer 3 is adjustable, and has a locking device for locking the adjusted size. Like this just c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com