Fabricated building automatic assembly production line system

A construction automation and production line technology, applied in construction, building components, building materials, etc., to ensure cleanliness, reduce labor, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

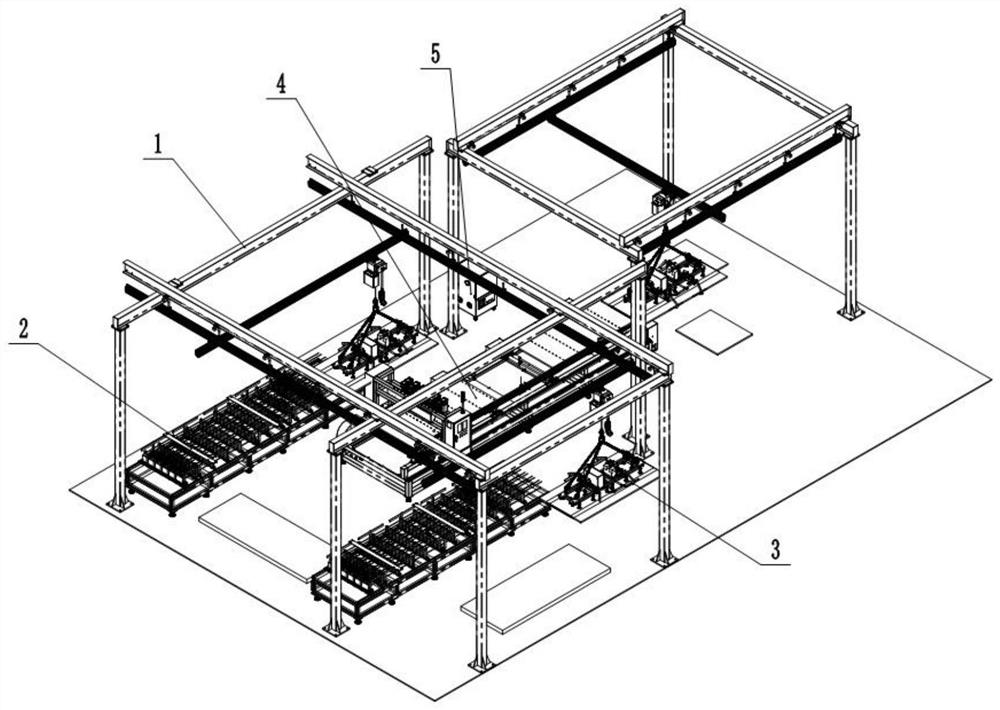

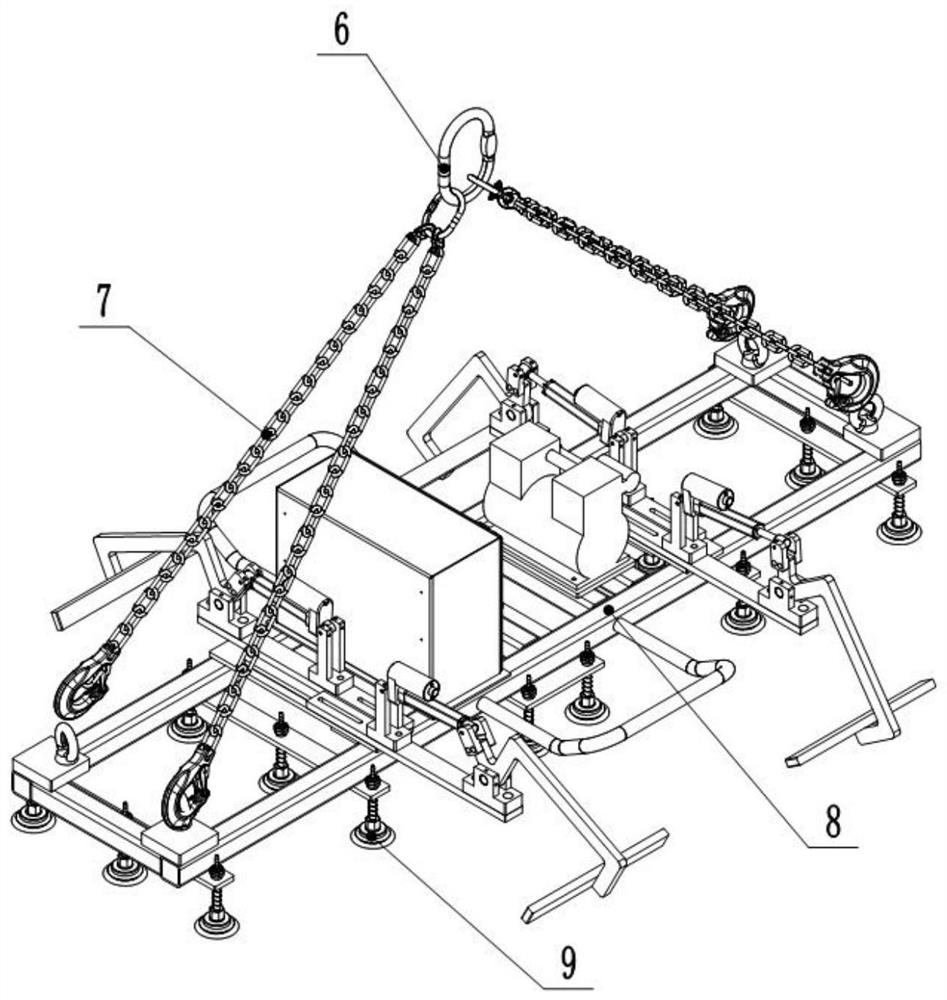

[0025] Basic attachment figure 1 As shown: an assembled building automatic assembly production line system, including truss 1, two assembly tables 2, three spreader 3, punching equipment 4 and vacuum cleaner 5, two assembly tables 2 are arranged in the punching equipment 4 On the side, the vacuum cleaner 5 is mounted on the side of the punching device 4. The three spreaders 3 are located above the two assembly tables 2 and the punching device 4, respectively, and the three spreader 3 slide on the truss 1, combined figure 2 As shown, the spreader 3 includes an electric hoist, a hanging ring 6, a rail chain 7, a bracket 8, and a vacuum chuck 9. The electric hoist is mounted on the truss 1, the hanging ring 6 is connected to the electric hoist, and the bracket 8 is connected to the ring 6. The vacuum suction cup 9 is mounted on the bracket 8.

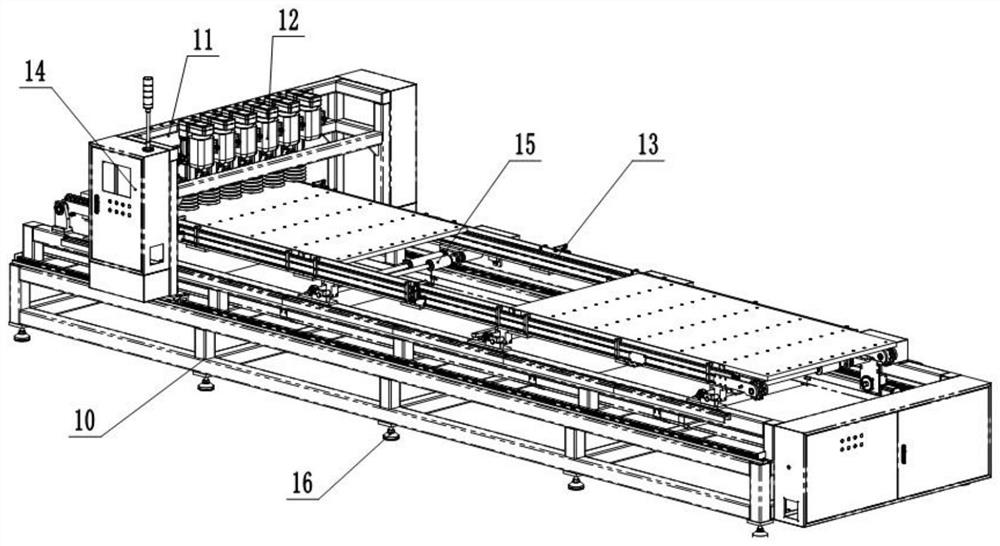

[0026] Combine image 3 As shown, the punching device 4 includes a rack 10, a gantry 11, a walking assembly, a punch assembly 12, a multiplier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com